Underwater rope fisher take-up and pay-off speed control device

A technology of speed control device and overshot, which is applied in the direction of extracting the undisturbed core device, earthwork drilling and mining, etc. It can solve the problems of rope skipping, entanglement to other parts of the subsea drilling rig, and failure of the subsea drilling rig to work normally, so as to achieve simple structure and avoid rope skipping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

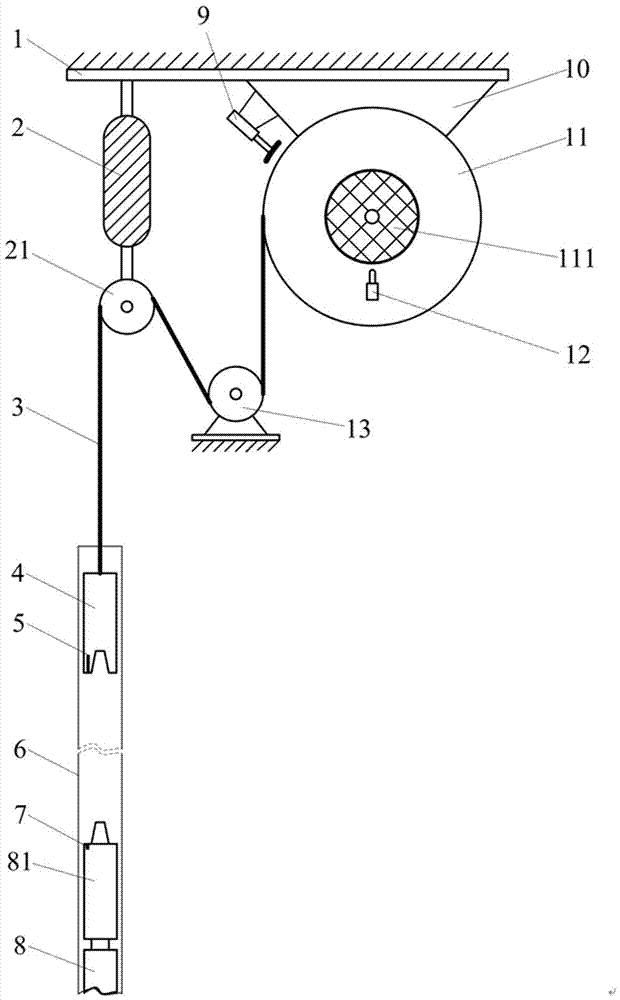

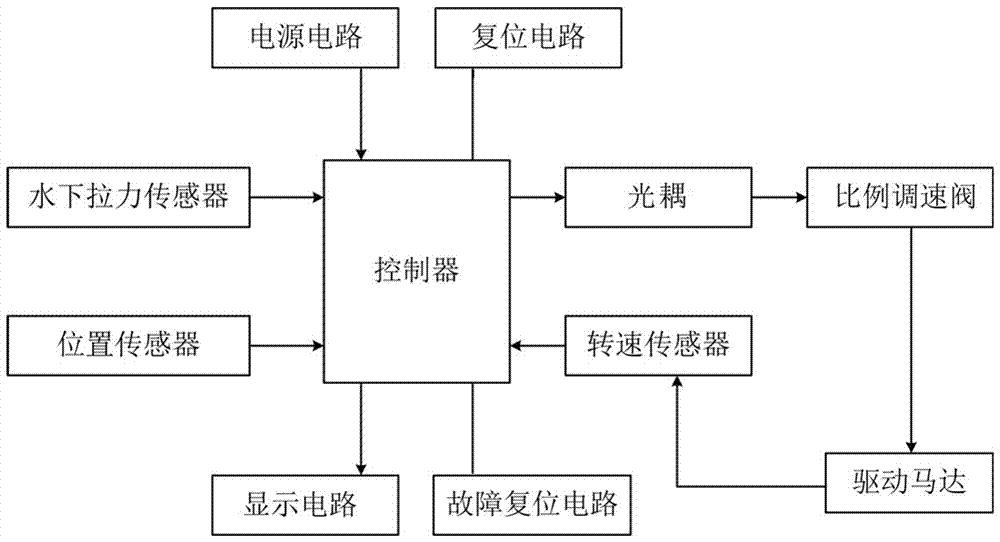

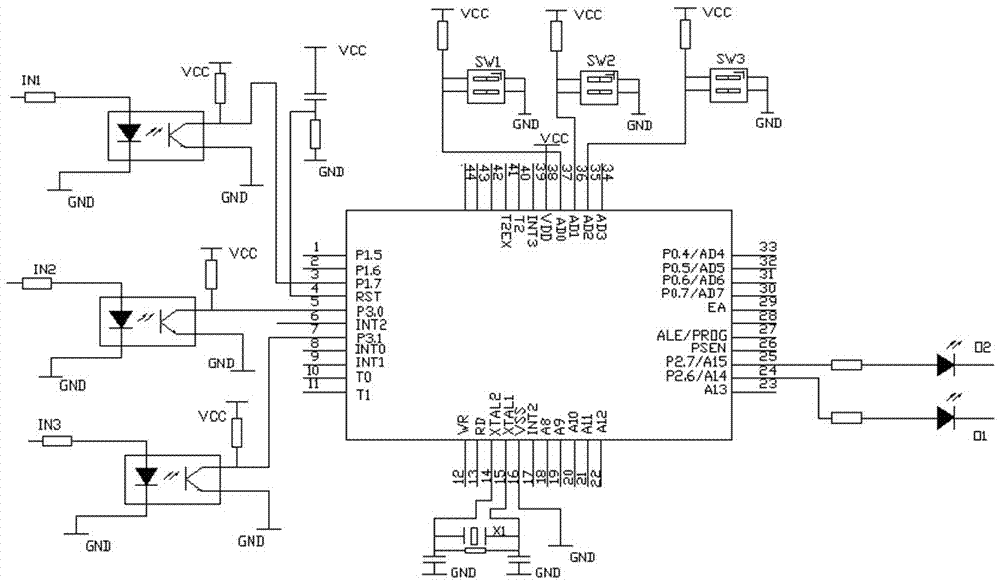

[0015] like figure 1 , figure 2 As shown, a speed control device for retracting and unwinding an underwater rope fisher includes a fisher 4, a rope 3, a hoist 11, an underwater pull force sensor 2, a position sensor 5, a rotational speed sensor 12, a fixed plate 1, a support plate 10, a control device, power supply, display circuit, reset circuit and fault reset circuit; the power supply is connected to the controller to provide working power for the entire control device; the support plate 10 is fixed on the fixed plate 1, and the hoist 11 is fixed on the support plate 10, and the hoist 11 below is provided with fixed pulley 13, and described underwater pulling force sensor 2 is positioned at winch 11 side, and underwater pulling force sensor 2 upper end is fixed on the fixed plate 1, and underwater pulling force sensor 2 lower end is provided with p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com