Waste wire recovery device

A recycling device and wire technology, which is applied in the field of waste wire recycling devices, achieves the effects of strong practicability, easy repair and maintenance, and simple and efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

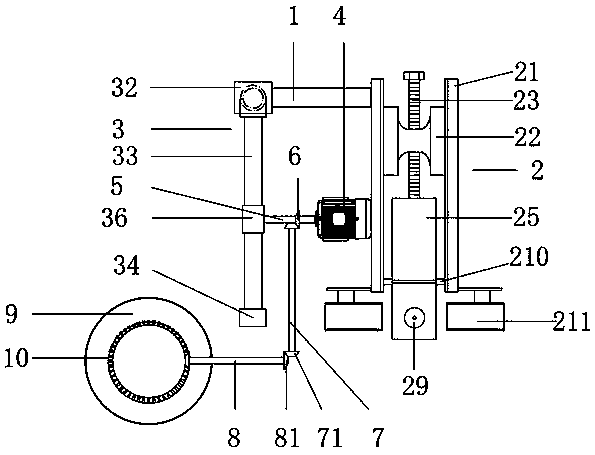

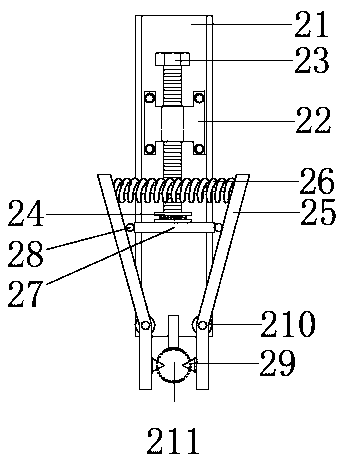

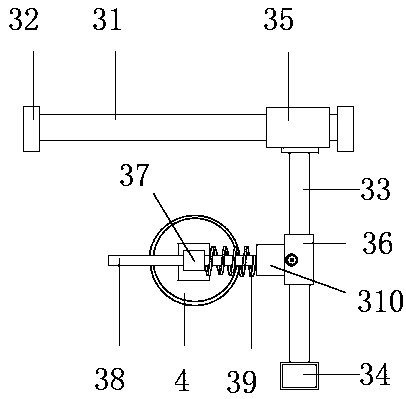

[0028] like Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: a waste wire recovery device, including a fixed bracket 1, a wire stripping mechanism 2 is connected to one side of the fixed bracket 1, and the fixed bracket 1 is far away from the wire stripping mechanism. 2 is connected to a wire swing mechanism 3, the wire stripping mechanism 2 is close to the side of the wire swing mechanism 3 and a servo motor 4 is fixedly connected between the wire stripping mechanism 2 and the wire swing mechanism 3, and the servo The output end of the motor 4 is connected to a No. 1 transmission rod 5 through a shaft coupling, and a No. 1 bevel gear 6 is fixedly connected to the No. 1 transmission rod 5, and a No. 2 transmission rod 7 is connected to the lower end of the No. 1 bevel gear 6. The end of the No. 2 transmission rod 7 away from the No. 1 bevel gear 6 is connected with the No. 3 transmission rod 8, and the end of the No. 3 transmission rod 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com