AGV capable of achieving automated waste recovery

A technology of waste recycling and trolley, which is applied in the field of automation, can solve the problems of production personnel walking around and prominent safety hazards, and achieve the effects of reliable operation, reduction of safety hazards, and economical use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate those skilled in the art to understand and realize the present invention, the technical solution of the present invention is now further described in conjunction with the drawings and specific embodiments.

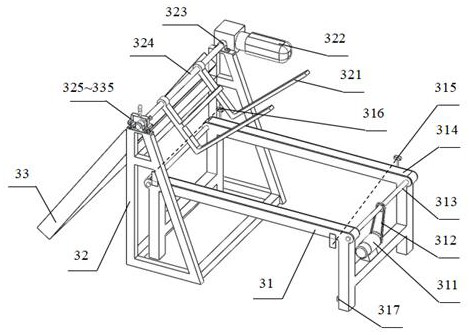

[0029] Such as Figure 5 As shown, the system mainly includes: waste bin 1, AGV trolley 2 and box turning machine 3.

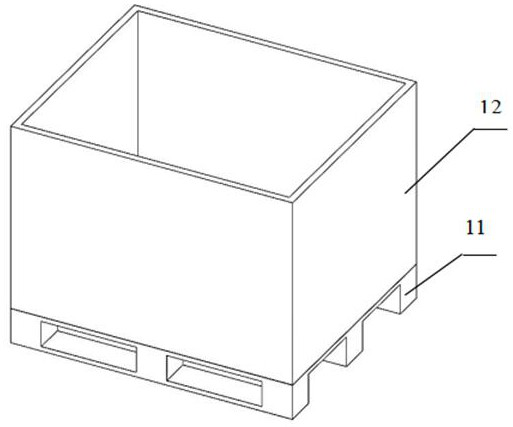

[0030] Such as figure 1 As shown, the waste bin 1 is composed of a standard pallet 11 and a frame 12 fixedly assembled, and the frame does not exceed the edge of the pallet to form a waste bin container. Preferably, standard pallet size: length x width x height = 1200mm x 1000mm x 150mm, four-way fork type.

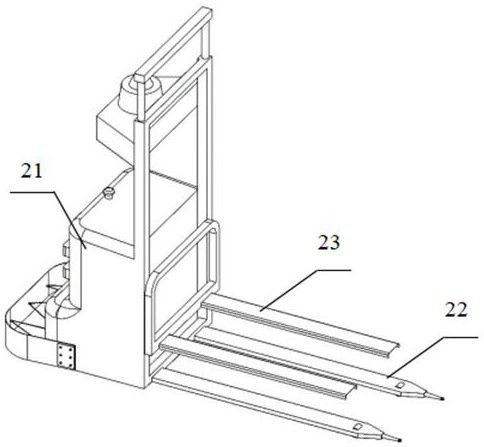

[0031] Such as figure 2 As shown, the AGV trolley 2 uses the existing AGV handling system to load waste recycling business on this basis. The method is: set the initial platform as waste bin 1 of the production unit, and set the target platform as box turning machine 3. Handling process setting: no-load state AGV tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com