Drum-type leftover material recovery device for non-woven fabric production

A recycling device and drum-type technology, applied in the field of drum-type scrap recycling devices for non-woven production, can solve the problems of low crushing efficiency and poor effect of non-woven fabrics, improve product quality and work efficiency, and achieve good crushing effect. The effect of meeting recycling needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

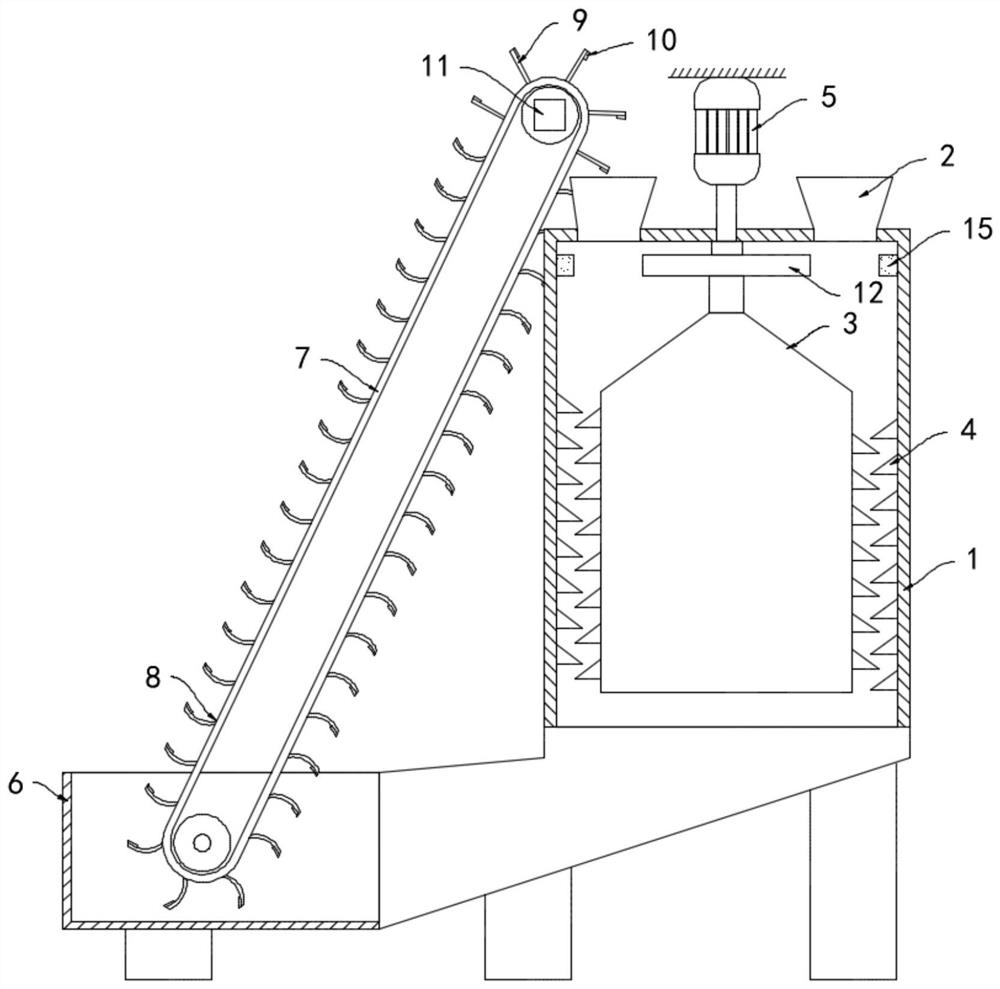

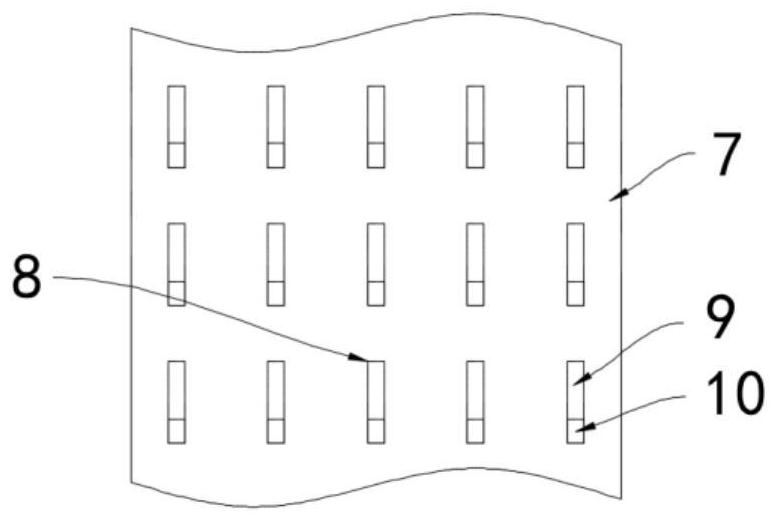

[0019] like Figure 1-3 As shown, a drum-type scrap recovery device for non-woven fabric production includes a cylindrical shell 1, the upper end of the cylindrical shell 1 is provided with a feeding port 2, and a crushing device is arranged inside the cylindrical shell 1 along its axial direction. Tube 3, the outer wall of the crushing tube 3 and the inner wall of the cylindrical shell 1 are equidistantly equipped with a plurality of crushing blades 4, and the plurality of crushing blades 4 are spirally arranged in a staggered manner, and the non-woven fabric can be crushed during the rotation and crushing process. Push down.

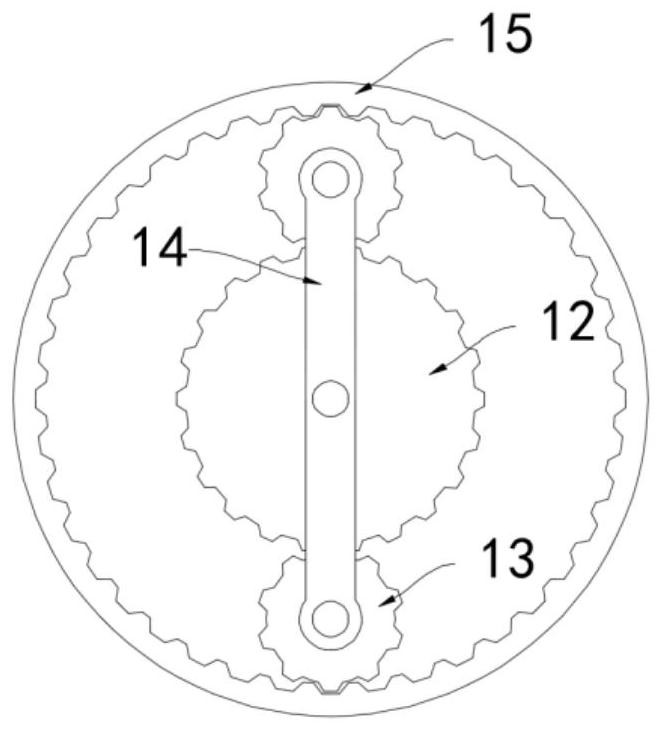

[0020] A driving motor 5 is arranged above the cylindrical housing 1, and the driving motor 5 is connected with the crushing cylinder 3 through a driving mechanism. Coaxially fixed, the outer ring of the driving gear 12 is meshed with two planetary gears 13, the upper end of the planetary gear 13 is connected to the rotating shaft along its axis, and ...

Embodiment 2

[0026] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that an air chamber 16 is provided in the crushing cylinder 3, an air inlet is provided at the upper end of the air chamber 16, and a fan 17 is coaxially installed on the inner wall of the air chamber 16. , The top surface of the air cavity 16 is installed with a helically wound conductive coil 18 , and the inner wall of the cylindrical housing 1 is installed with a ring magnet 19 .

[0027] In this embodiment, when the crushing cylinder 3 rotates, it drives the conductive coil 18 and the fan 17 to rotate. According to the principle of electromagnetic induction, when the magnetic flux in the closed coil changes, an induced current will be generated in the closed coil, and the conductive coil 18 will generate an induced current. Induction current is generated, electric energy is converted into heat energy to generate heat, no external power supply is needed, and the problem of external wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com