Crushed thing drying machine

The technology of a dryer and a box body is applied in a field, and can solve the problems of uneven drying degree, reducing the processing quality of the object to be dried, and poor control of air flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

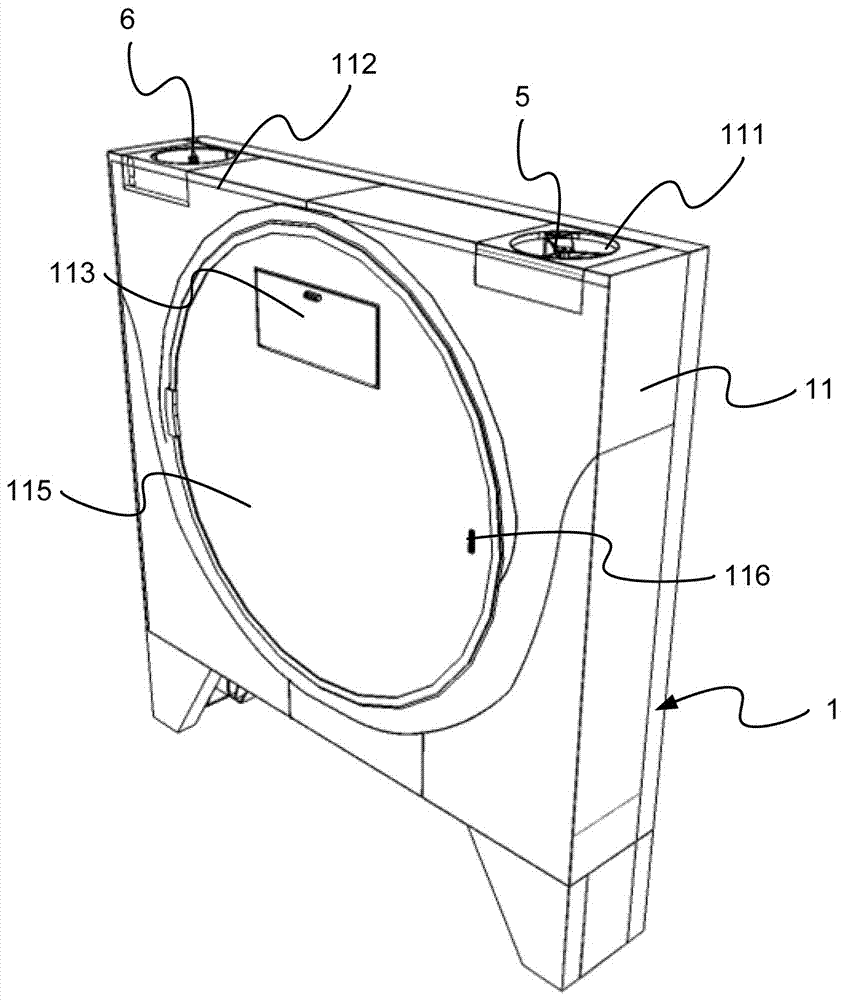

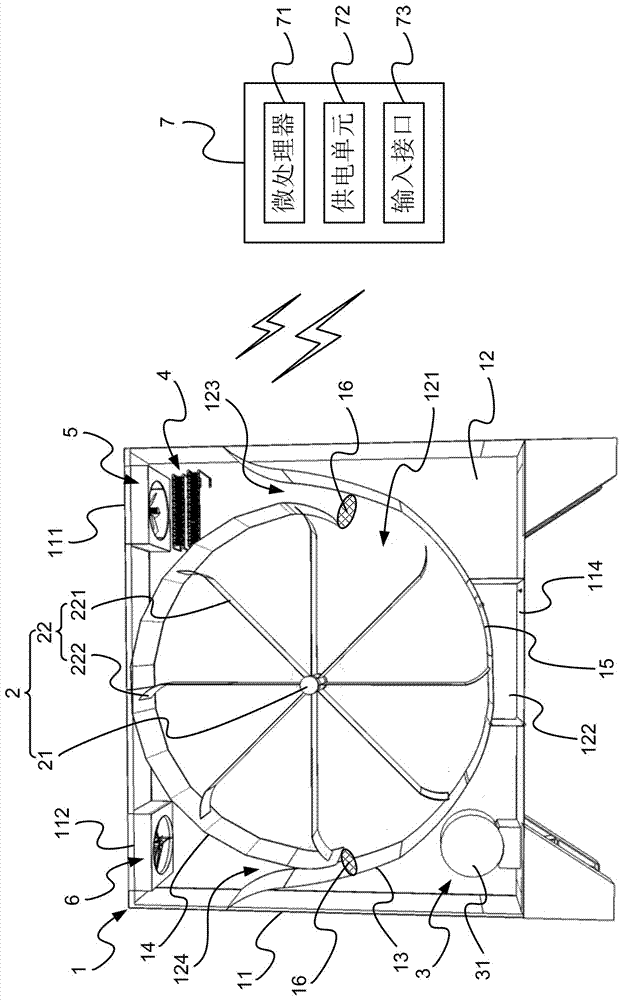

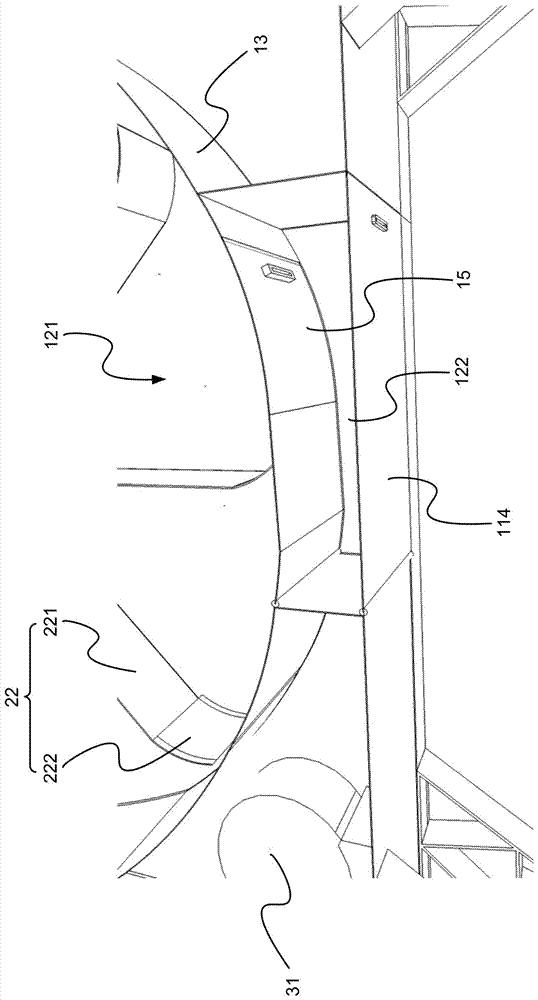

[0061] see Figure 1-Figure 5Shown are the schematic diagram of the appearance of the crumb dryer of the present invention, the schematic diagram of the internal chamber of the crumb dryer of the present invention, the enlarged schematic diagram of a part of the internal chamber of the crumb dryer of the present invention, and the Another partially enlarged schematic diagram of the inner chamber of the inventive crumb dryer, and a schematic diagram of the back of the chamber of the inventive crumb dryer. As shown in the figure: the present invention is a debris dryer, which includes a drying box 1, an agitator 2, a driver 3, several heaters 4 with heat radiation and heat dissipation films, an exhaust fan 5, an exhaust Air fan 6, and controller 7 constitute.

[0062] The upper sides of the shell 11 of the above-mentioned drying box 1 are respectively provided with an air inlet 111 and an air outlet 112, and the front is provided with an inlet door 113, and the bottom is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com