Plate-shaped thing drying machine

A technology of plate-like objects and dryers, which is applied in the directions of dryers, drying, and drying gas arrangement, can solve the problems of easy differences in drying degree, difficult temperature, and limited drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

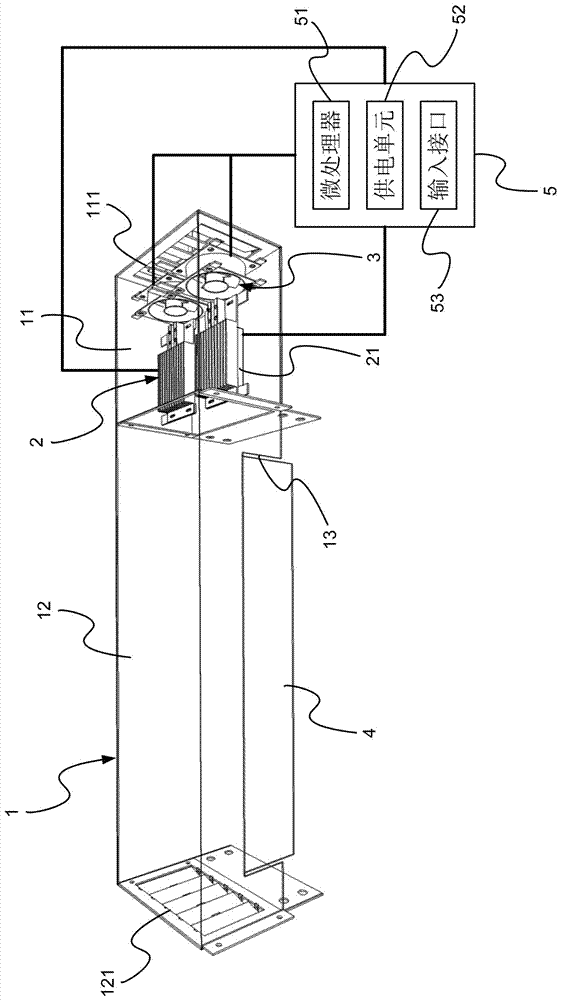

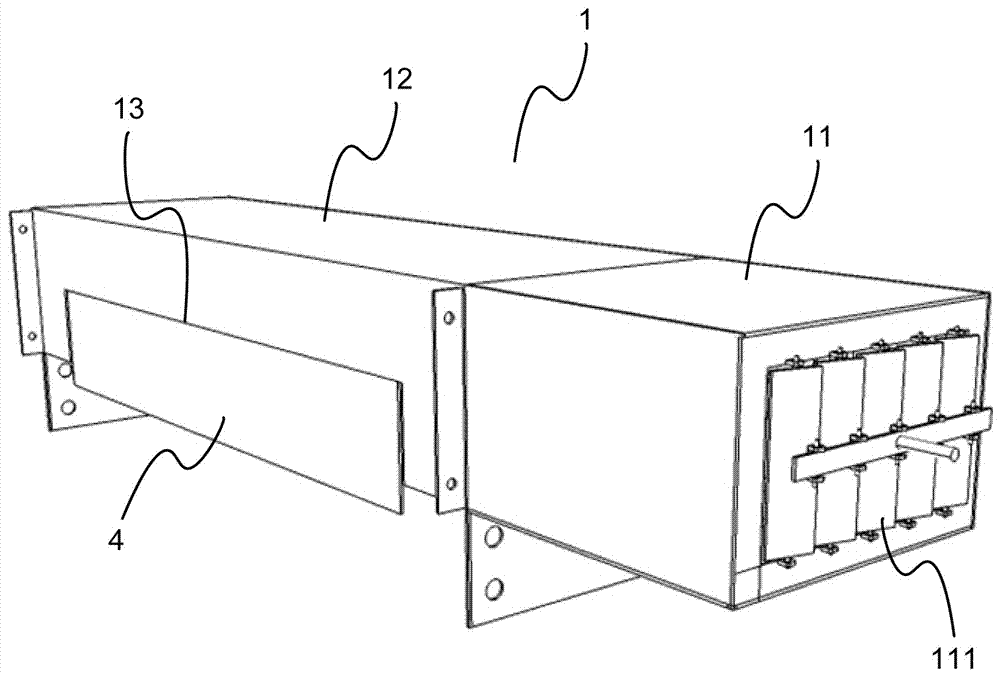

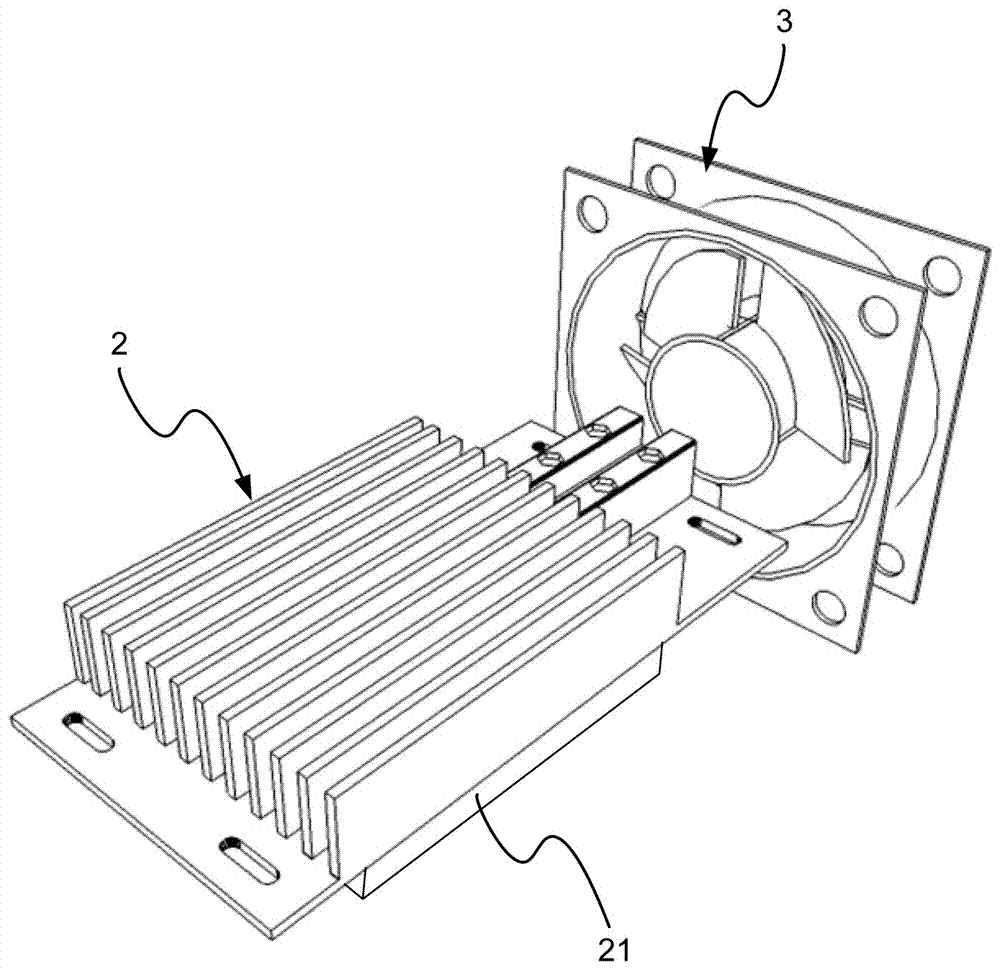

[0045] see Figure 1-Figure 3 As shown, they are the schematic diagram of the first embodiment of the plate dryer of the present invention, the appearance schematic diagram of the first embodiment of the plate dryer of the present invention, and the structure diagram of the heater and fan with heat radiation film of the present invention . As shown in the figure: the present invention is a plate dryer, which includes a drying box 1, several heaters 2 with heat radiation and cooling films, at least one fan 3, movable parts 4, and a controller 5 constituted.

[0046] The above-mentioned drying cabinet 1 is provided with a chamber 11 and a channel 12 communicating with the chamber 11, and the drying cabinet 1 is provided with an air inlet 111 at one end of the chamber 11, and the drying cabinet The body 1 is installed on a conveying platform and is provided with an opening 13 on the side for allowing plates to pass in and out of the passage 12. The air port 111 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com