Gearbox simulation test system

A test system and gearbox technology, which is applied in the field of transmission system simulation devices, can solve the problems of lengthening the development cycle, the inability to detect conceptual design and modeling defects in time, and extremely high safety requirements, so as to shorten the development cycle, The effect of improving development and testing efficiency, reducing development costs and risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

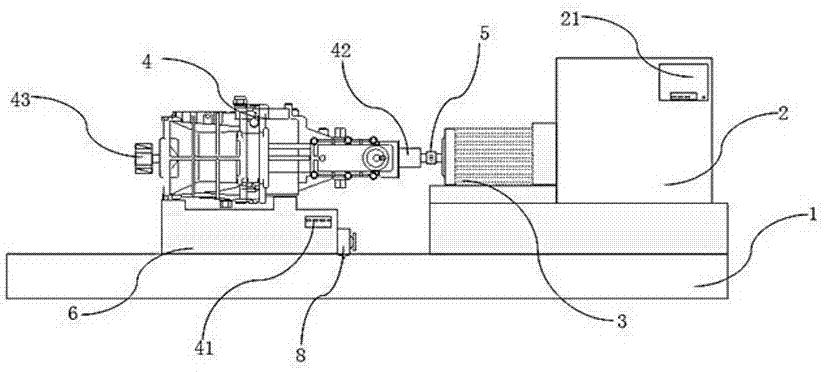

[0036] Such as figure 1 As shown, a gearbox simulation test system includes a workbench 1, a host 2, a drive motor 3, a gearbox 4, a gearbox controller 41, a connecting mechanism 5, a support 6 and measuring components. The host 2 is set at In the non-action area of the workbench 1, the drive motor 3 is fixed at one end of the workbench 1, the drive motor 3 is connected to the input shaft 42 of the gearbox 4 through the connecting mechanism 5, and the gearbox 4 is connected to the work station through the support 6 Station 1 is fixedly connected.

[0037] The support 6 is provided with a guide bearing bracket (not shown in the figure, adopting a conventional guide bearing support structure in the prior art), a guide bearing is provided on the guide bearing bracket, and the guide bearing positions the gearbox 4 A sensor is arranged on the guide bearing support, and the sensor feeds back information to the host 2, and the sensor is a vibration sensor and a rotational speed sensor...

Embodiment 2

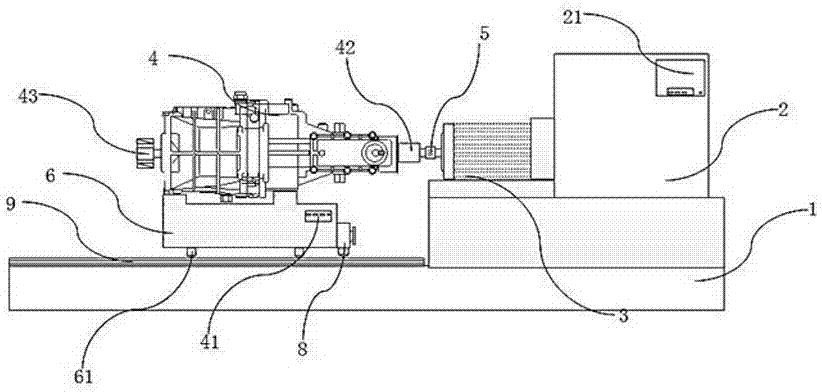

[0042] Such as figure 2 As shown, a gearbox simulation test system includes a workbench 1, a host 2, a drive motor 3, a gearbox 4, a gearbox controller 41, a connecting mechanism 5, a support 6 and measuring components. The host 2 is set at In the non-action area of the workbench 1, the drive motor 3 is fixed at one end of the workbench 1, the drive motor 3 is connected to the input shaft 42 of the gearbox 4 through the connecting mechanism 5, and the gearbox 4 is connected to the work station through the support 6 Station 1 is fixedly connected. The support 6 is provided with a guide bearing bracket (not shown in the figure, adopting a conventional guide bearing support structure in the prior art), a guide bearing is provided on the guide bearing bracket, and the guide bearing positions the gearbox 4 A sensor is arranged on the guide bearing support, and the sensor feeds back information to the host 2, and the sensor is a vibration sensor and a rotational speed sensor. A s...

Embodiment 3

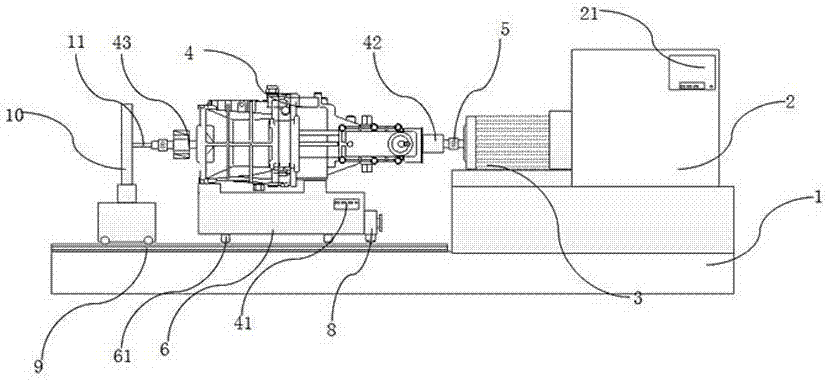

[0047] Such as image 3 As shown, a gearbox simulation test system includes a workbench 1, a host 2, a drive motor 3, a gearbox 4, a gearbox controller 41, a connecting mechanism 5, a support 6 and measuring components. The host 2 is set at In the non-action area of the workbench 1, the drive motor 3 is fixed at one end of the workbench 1, the drive motor 3 is connected to the input shaft 42 of the gearbox 4 through the connecting mechanism 5, and the gearbox 4 is connected to the work station through the support 6 Station 1 is fixedly connected. The support 6 is provided with a guide bearing bracket (not shown in the figure, adopting a conventional guide bearing support structure in the prior art), a guide bearing is provided on the guide bearing bracket, and the guide bearing positions the gearbox 4 A sensor is arranged on the guide bearing support, and the sensor feeds back information to the host 2, and the sensor is a vibration sensor and a rotational speed sensor. A sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com