On-line test method used for surface acoustic wave filter

A surface acoustic wave, online testing technology, applied in electronic circuit testing, instruments, measuring electricity and other directions, can solve the problems of cumbersome, error, large testing workload, etc., to improve production efficiency, reduce supply pressure, realize automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

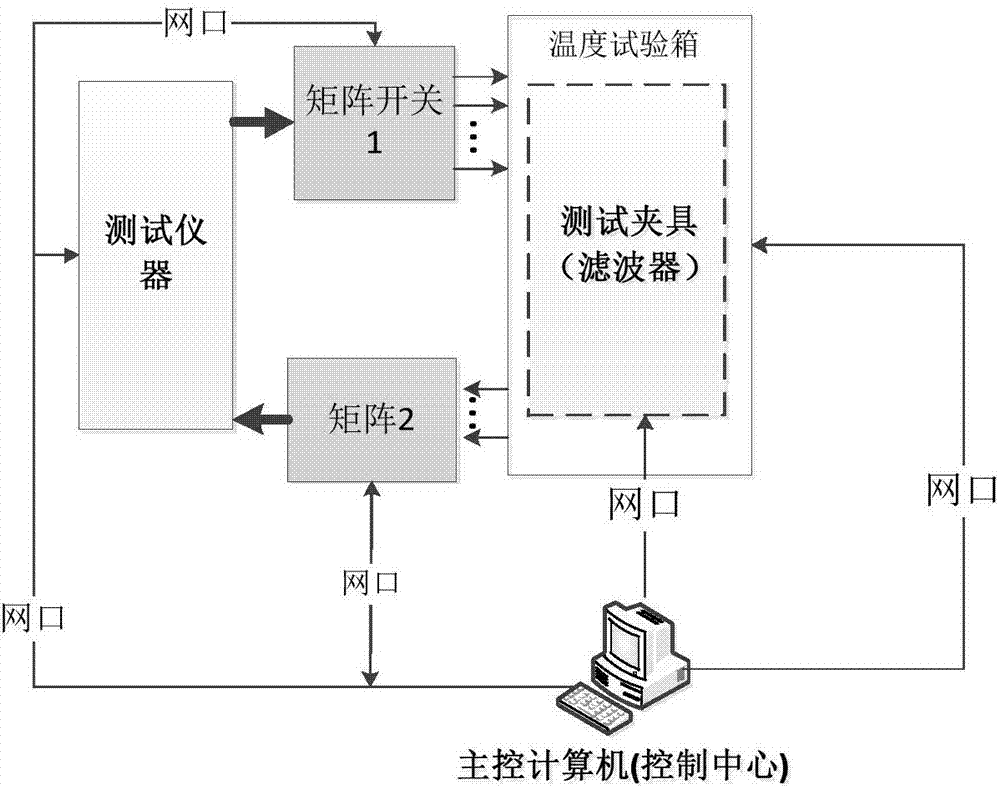

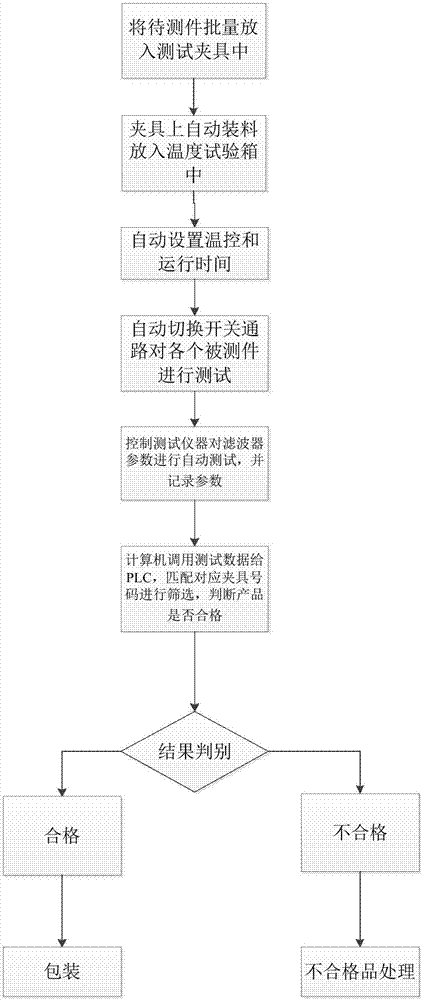

[0035] An online testing method applied to surface acoustic wave filters, using an online testing system for large quantities of wide temperature range surface acoustic wave filters, such as figure 1 As shown, it is mainly composed of computer, temperature test box, test fixture, matrix switch and test instrument;

[0036] The computer is used as the general control to control the temperature test chamber, matrix switch (two sets), temperature test chamber, test fixture, test instrument and other equipment through the network cable.

[0037] The test instrument is controlled through the network cable to control the input and output characteristics of the signal. The two ports of the test instrument are respectively tested through two matrix switches and the filter on the fixture in the incubator. The main control computer can control the on-off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com