A roller mill improving wire and cable manufacturing quality

A wire and cable and rolling mill technology, applied in the field of rolling mills, can solve the problems of different shapes and sizes of scrap copper, waste of resources, and difficulty in recycling scrap copper, and achieve rapid sorting and rolling, improve quality, and improve recycling. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

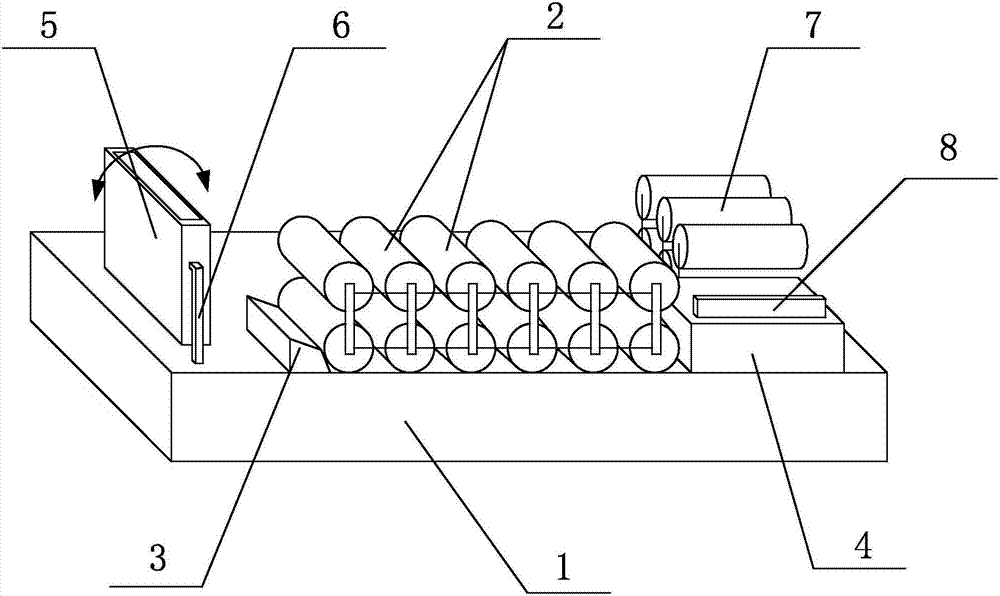

[0022] Such as figure 1 As shown, the rolling mill for improving the quality of wire and cable preparation in the present invention includes a workbench 1, and the workbench 1 is provided with multiple groups of longitudinal rollers 2 arranged in parallel, and the front ends of the multiple groups of longitudinal rollers 2 are provided with a feeding table 3. The rear end of multiple groups of longitudinal rollers 2 is provided with a discharge table 4, and a feed hopper 5 is provided beside the feed table 2, and an outlet is provided at the lower end of the upper opening of the feed hopper 5, and an outlet is provided at the outlet. switch, the two sides of the feed hopper 5 are connected to the workbench through the support rod 6, the two sides of the feed hopper 5 are hinged with the support rod 6, and the feed hopper 5 turns up and down around the hinge with the support rod 6, One side of the discharge platform 4 is provided with a plurality of sets of horizontal rollers 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com