Transformer manufacturing method capable of increasing output

A technology to improve output and transformers, applied in the manufacture of inductors/transformers/magnets, transformers/inductor cores, coils, etc., can solve the problems of reducing product production capacity and production efficiency, time-consuming winding process, and not in line with economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

[0040] Such as figure 1 As shown, a flow chart of the steps of Embodiment 1 of a method for preparing a transformer that can increase output includes the following steps:

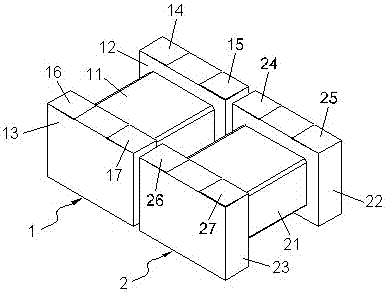

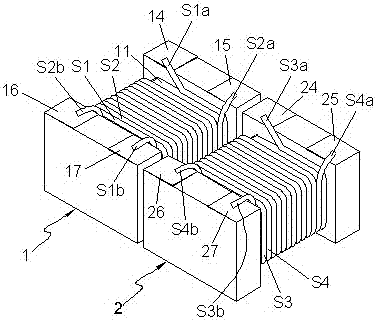

[0041] Step 1, material preparation steps, please refer to figure 2As shown, the material preparation step is to provide a first magnetic core 1 and a second magnetic core 2, the first magnetic core 1 has a first winding part 11 and a pair of first winding parts 11 connected to both ends of the first winding part 11 respectively. The flange 12 and the second flange 13, the top surface of the first flange 12 is provided with the first terminal electrode 14 and the second terminal electrode 15, and the top surface of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com