LNG optimum control reliquefaction system for recovering LNG low-temperature waste heat generated during LNG vaporization

A reliquefaction, cryogenic technology for gas/liquid distribution and storage, fixed-capacity gas storage tanks, container discharge methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

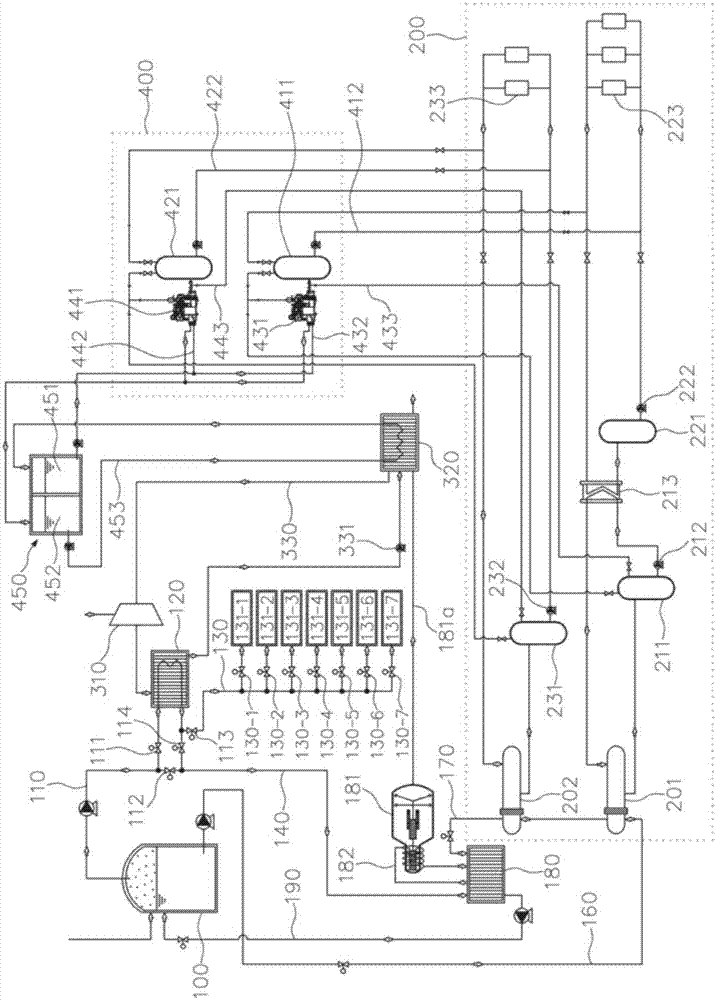

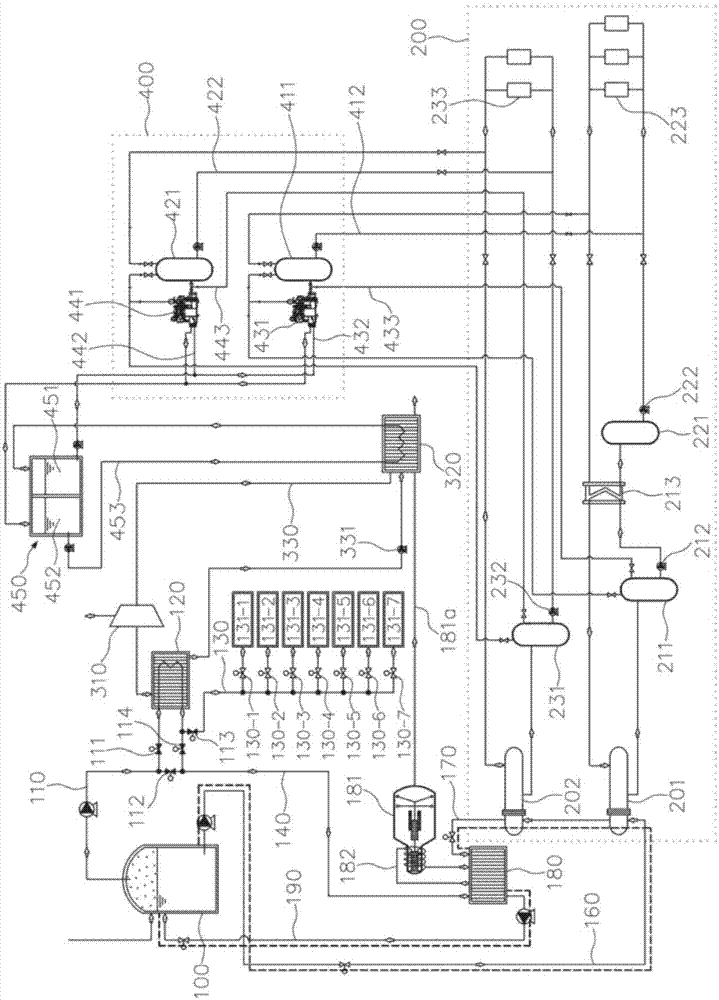

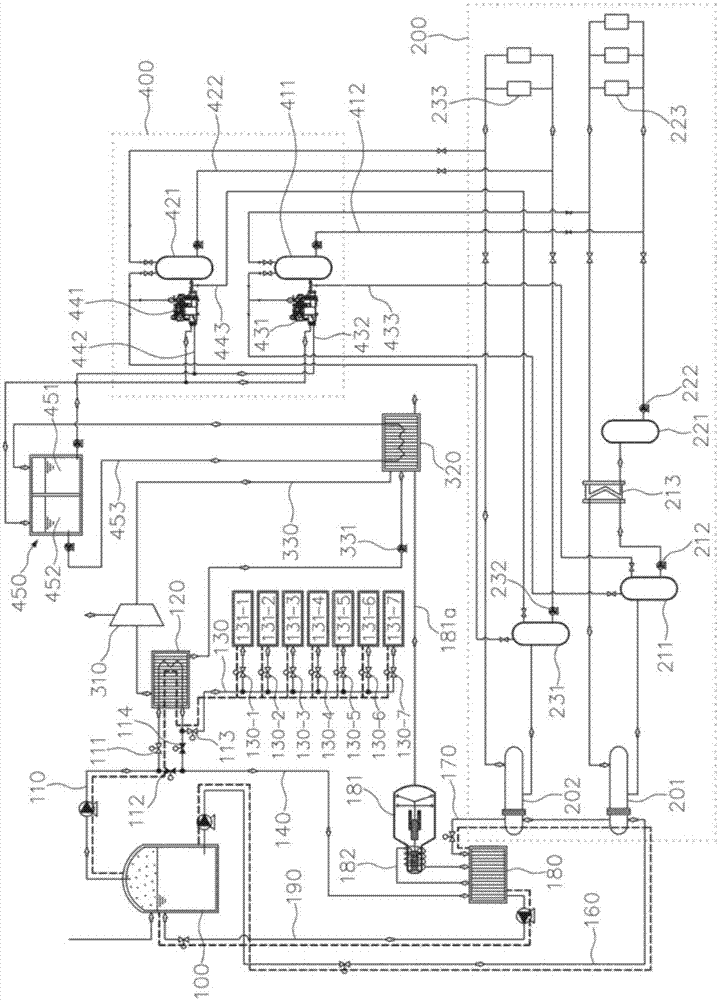

[0017] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those having ordinary knowledge in the technical field to which the present invention pertains can easily implement. However, the present invention can be implemented in various ways and is not limited to the embodiments described here. In addition, in order to clarify the present invention, in the drawings, parts irrelevant to the description are omitted, and similar reference numerals are assigned to similar parts throughout the specification.

[0018] Throughout the specification, when it is described that a certain part "includes" a certain constituent element, if there is no specific contrary statement, it means that other constituent elements are not excluded, but may also include other constituent elements.

[0019] The specific kinds of refrigerants above and below are just one example, and different kinds of refrigerants can be used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com