Device and method for underwater repair of a hole of a nuclear reactor part

A technology for nuclear reactors and repair methods, applied in the direction of reactor fuel elements, reactors, milling machine equipment, etc., can solve problems such as redundancy and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

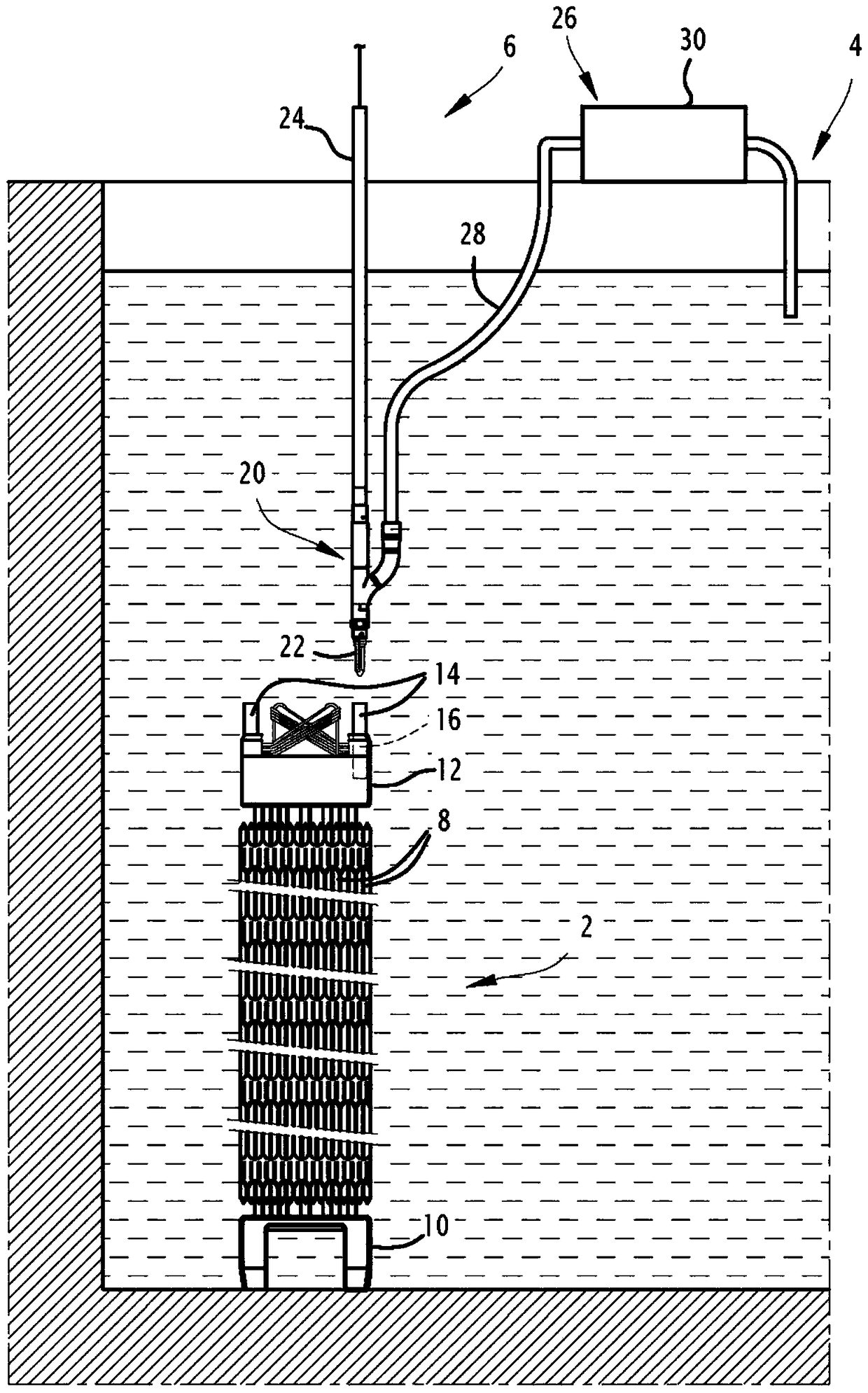

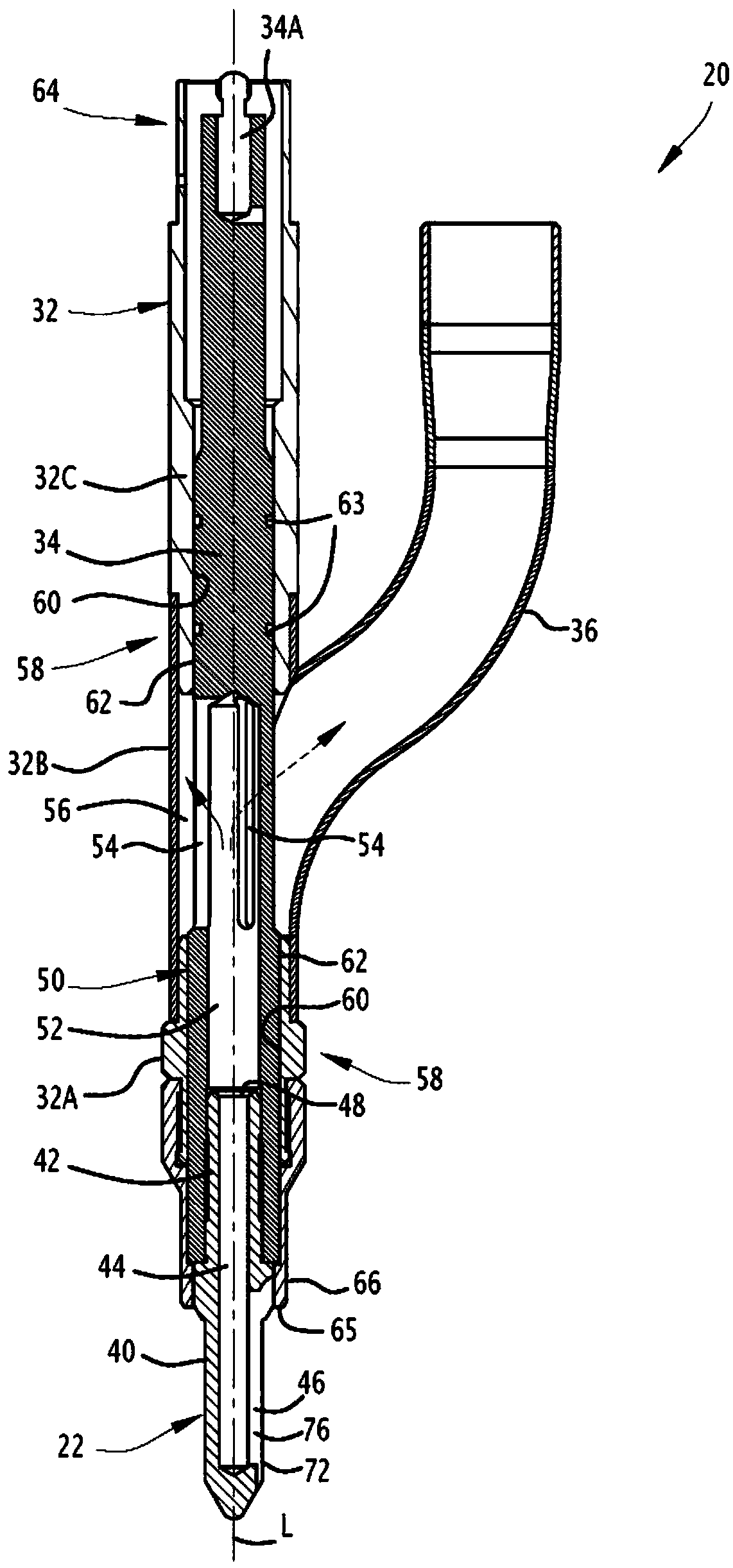

[0043] exist figure 1 In , a damaged nuclear fuel assembly 2 is placed underwater in a pool 4 of a nuclear power plant to be repaired using a repair system 6 .

[0044] The nuclear fuel assembly 2 comprises a bundle of elongated nuclear fuel rods 8 extending between a lower header 10 provided for placement on the lower core plate of a reactor in a nuclear power plant and an upper header 12, the upper tube The seat 12 is provided against the upper core plate of a reactor of a nuclear power plant. exist figure 1 In this case, the nuclear fuel assembly 2 is vertical, with the lower stem 10 at the bottom and the upper stem 12 at the top.

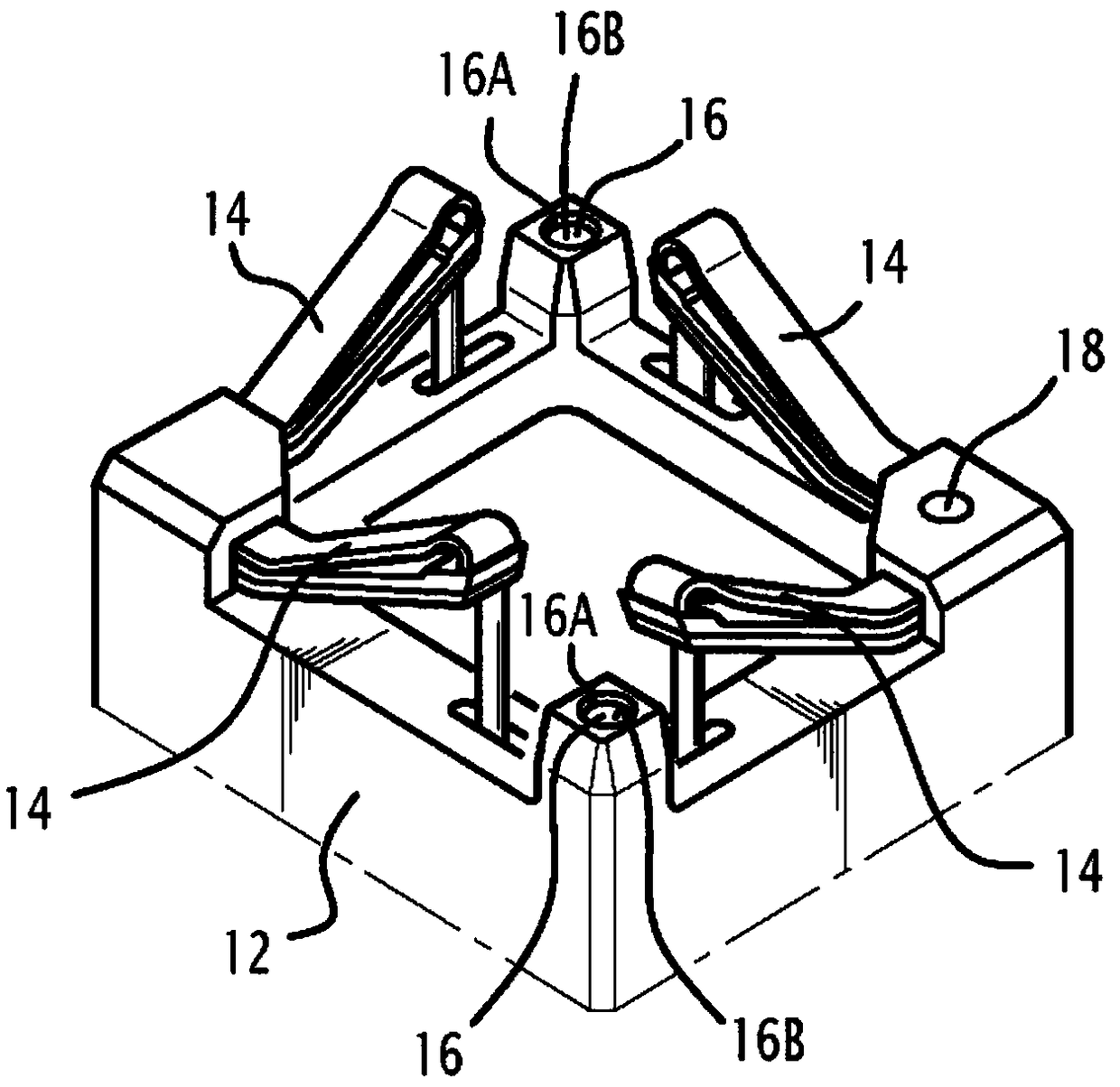

[0045] Conventionally, the top nozzle 12 includes a spring 14 provided against the top core plate in order to push the nuclear fuel assembly 2 downwards.

[0046] Such as figure 2 As shown, the upper nozzle 12 is provided with centering holes 16, each centering hole 16 being intended to receive a corresponding centering pin of the upper cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com