Visible light photocatalyst for efficient reduction of hexavalent chromium and preparation method of visible light photocatalyst

A visible light, titanium dioxide technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as limited application, achieve high specific surface area, improve efficiency, and simple and convenient experimental steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

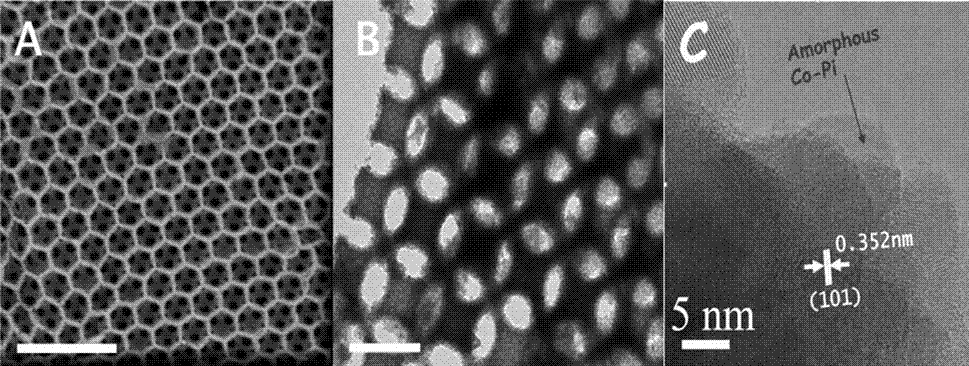

[0028] Preparation of inverse opal-structured titanium dioxide (i.o.TiO 2 )

[0029] Mix 26 mL of ethanol, 1 mL of acetylacetone (AcAc), 5.6 mL of isopropyl titanate (TTIP), 0.85 mL of hydrochloric acid (HCl), and 4.6 mL of deionized water, and stir at room temperature for about 2 hours to obtain a perfusate. Spread the prepared PS template monolayer on the petri dish, add the perfusion solution dropwise to the PS template, and keep the liquid level equal to the PS template. Dry overnight in air at 25°C, and then calcine in air at 500°C for 4 hours to remove the organic template after complete drying. After cooling, the samples were obtained by grinding.

Embodiment 2

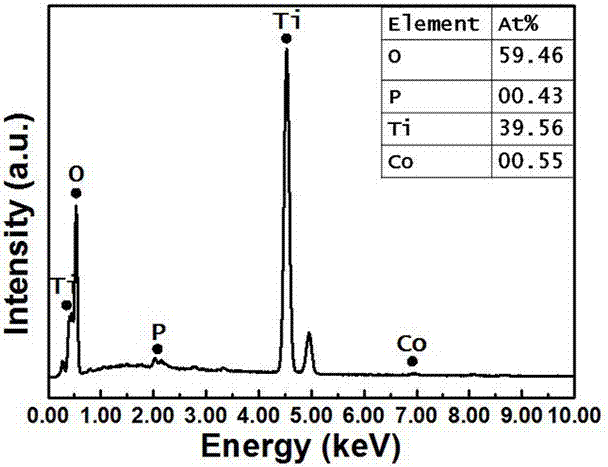

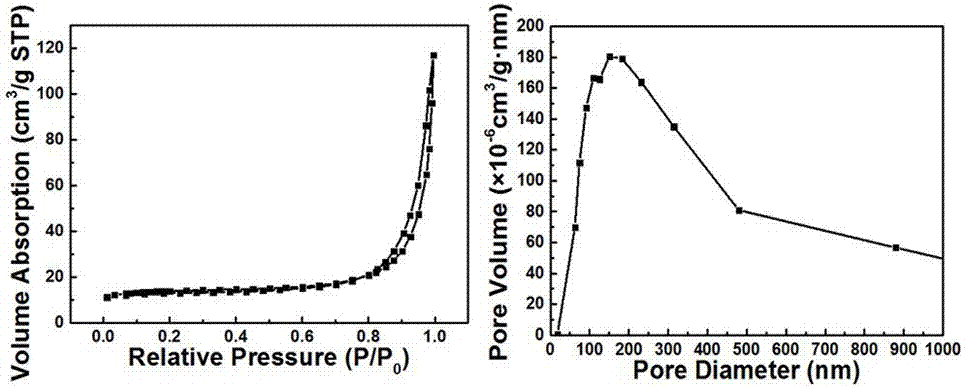

[0031] Preparation of cobalt phosphate-supported inverse opal titania (Co-Pi / i.o.TiO 2 )

[0032] Mix 26 mL of ethanol, 1 mL of acetylacetone (AcAc), 5.6 mL of isopropyl titanate (TTIP), 0.85 mL of hydrochloric acid (HCl), and 4.6 mL of deionized water, and stir at room temperature for about 2 hours to obtain a perfusate. Spread the prepared PS template monolayer on the petri dish, add the perfusion solution dropwise to the PS template, and keep the liquid level equal to the PS template. Dry overnight in air at 25°C, and then calcine in air at 500°C for 4 hours to remove the organic template after complete drying. After cooling, grind to get i.o.TiO 2 sample. Dissolve 0.005 M sodium dihydrogen phosphate and 0.005 M disodium hydrogen phosphate in 50 mL deionized water and adjust to pH=7. After the solution was sonicated for 3 min, 0.5 mM cobalt nitrate hexahydrate was added to the solution, and after it was completely dissolved, 0.3 gi.o.TiO was added to the solution 2 pow...

Embodiment 3

[0034] Preparation of cobalt phosphate-supported P25 samples (Co-Pi / P25)

[0035] Dissolve 0.005 M sodium dihydrogen phosphate and 0.005 M disodium hydrogen phosphate in 50 mL deionized water and adjust to pH=7. After the solution was sonicated for 3 min, 0.5 mM cobalt nitrate hexahydrate was added to the solution, and after it was completely dissolved, 0.3 g of P25 powder was added to the solution, and the mixed solution was placed under a 1000 w 302 nm ultraviolet mercury lamp and stirred for 30 min, then centrifuged and washed with water Dry and grind to get the sample (Co-Pi / i.o.TiO 2 ).

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap