Method and apparatus for transferring a printed substance to a substrate by means of a laser beam

A laser, material technology, applied in printing, laser, laser parts and other directions, can solve the problems of high power, uneven transfer of printing materials, etc., to achieve the best interaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

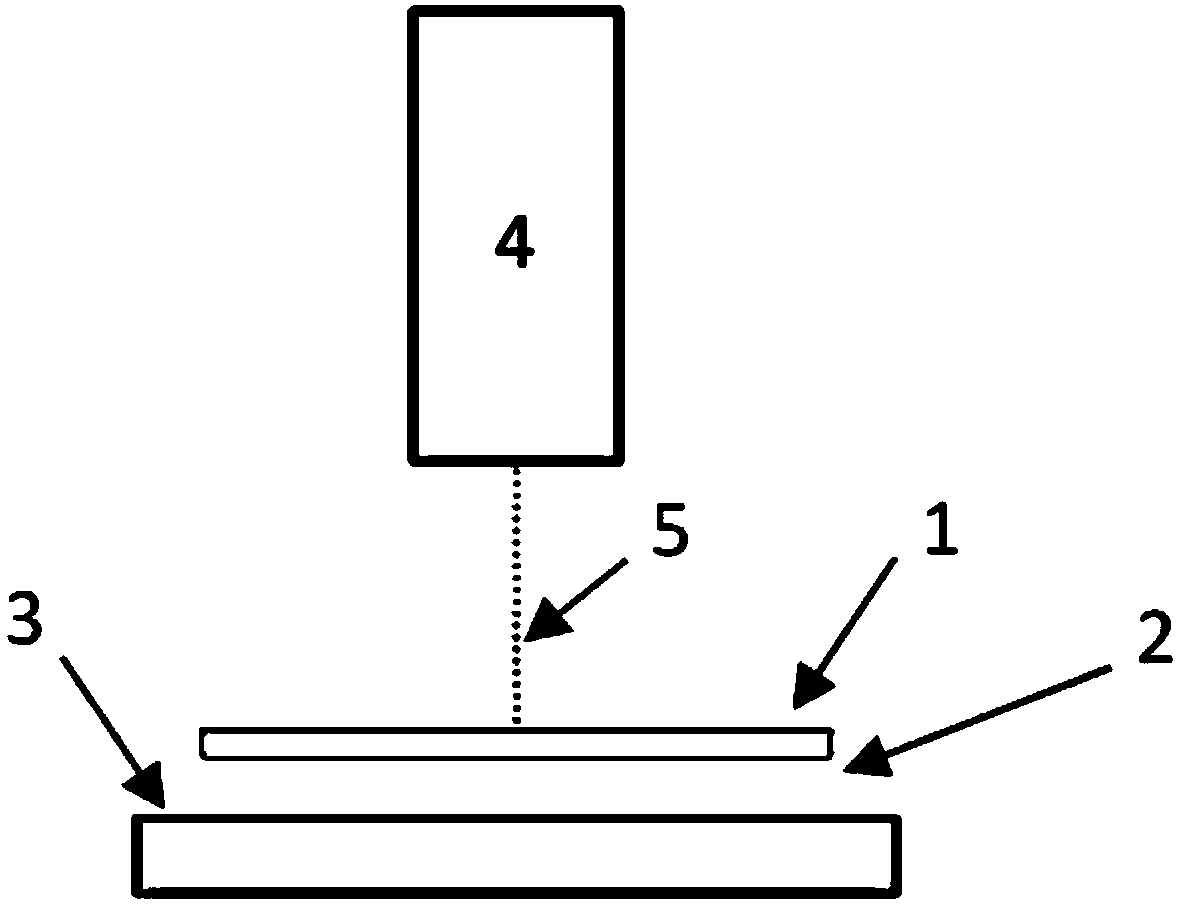

[0035] figure 1 A simple embodiment of a device for carrying out the transfer process according to the invention is shown. The stationary or stationary carrier 1 has a coating with a printing substance 2 . To transfer the printing substance 2 onto the substrate 3 , the optical unit 4 deflects a laser beam 5 from a laser beam source (not shown) onto the carrier 1 with the printing substance 2 . As a result of the thermal energy input, the printing substance is transferred from the carrier 1 to the substrate 3 selectively or spatially resolved, for example in the form of dots or lines. In addition to the deflection of the laser beam 5 , the carrier 1 and / or the substrate 3 can also be implemented in a translational movement in order to expand the available working space in this way.

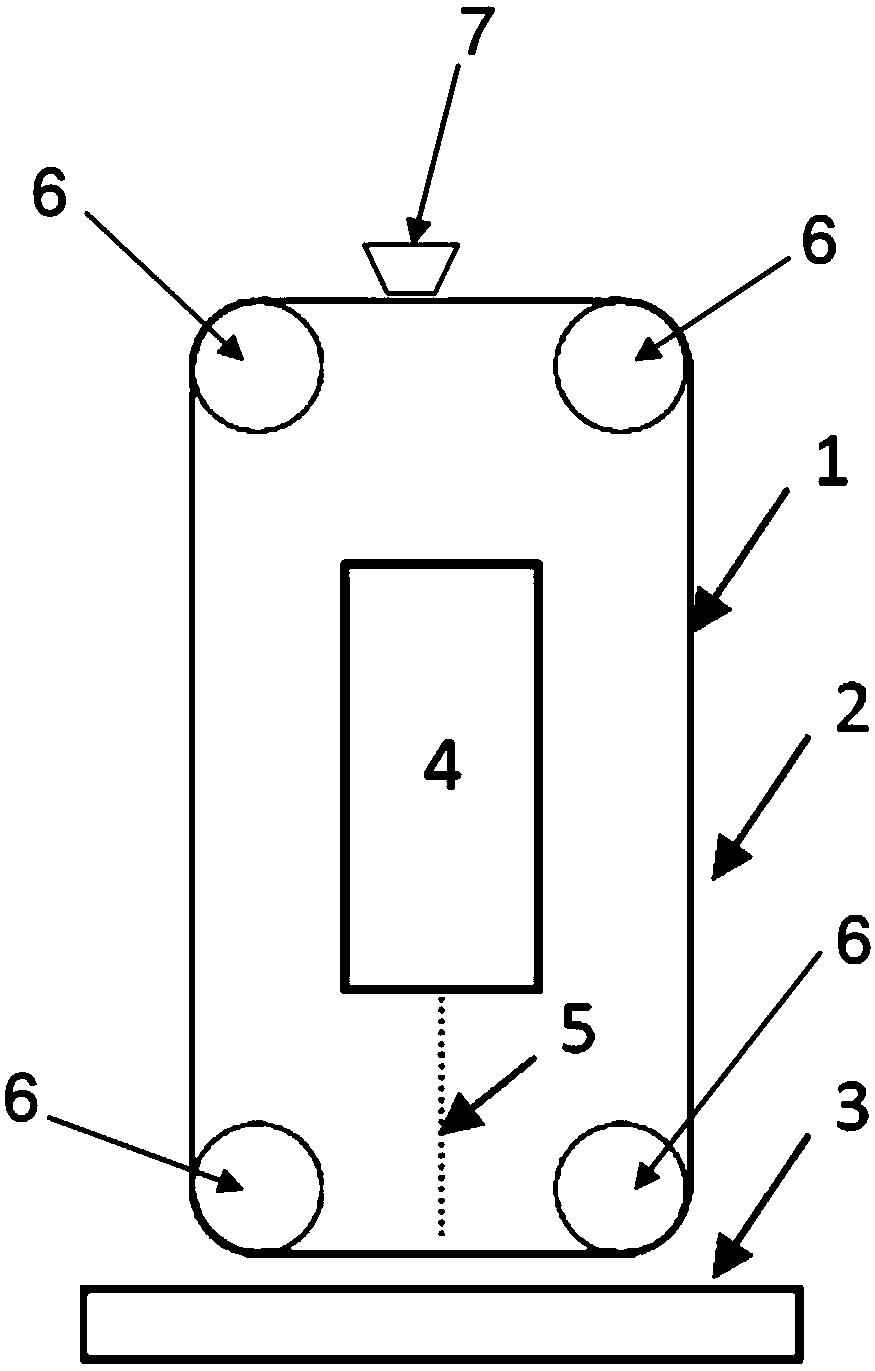

[0036] figure 2 Another embodiment of the device is shown. The carrier 1 is designed as an endless belt and is guided in particular continuously over four guide rollers 6 . The carrier 1 is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com