Photovoltaic board group mobile cart

A technology for moving carts and photovoltaic panel groups, which is applied to trolleys, motor vehicles, multi-axis carts, etc., can solve the problems of photovoltaic panel group bumping, time-consuming and laborious handling, etc., and achieves stability, convenience, and transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

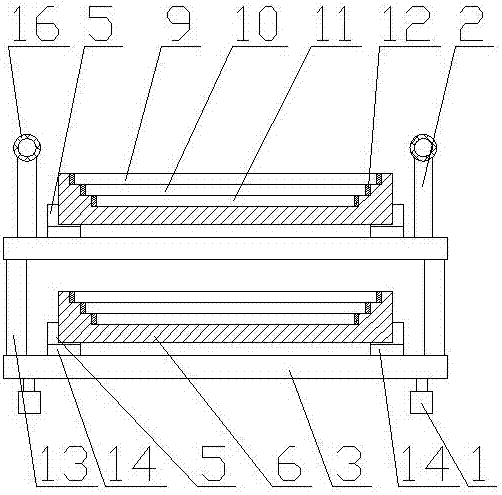

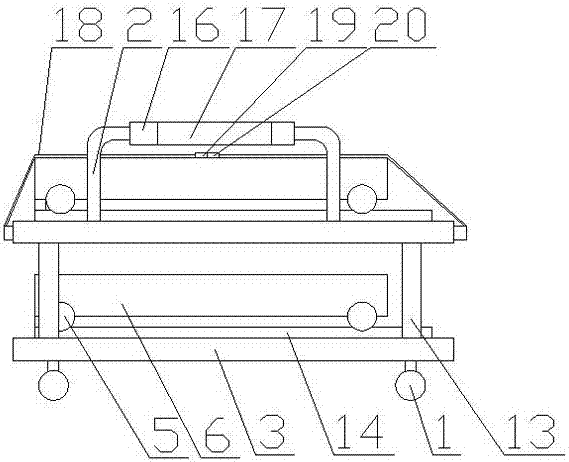

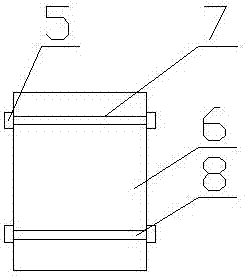

[0035] Such as figure 1 , 2 As shown in and 3, the mobile trolley of the photovoltaic panel group includes a placement device, universal wheels 1 and handrails 2, and the placement device includes a storage board 3, guide rails, pulleys 5 and a photovoltaic panel group placement tank 6, and the storage board 3 is equipped with There is a shaft groove 7 on the bottom surface of the photovoltaic panel group placement tank 6, and a shaft 8 is installed in the shaft slot 7. The pulley 5 is installed at both ends of the shaft 8. The pulley 5 cooperates with the guide rail, and the photovoltaic panel group placement tank body 6 is slidably connected with the storage board 3; the photovoltaic panel group placement groove body 6 is provided with a first photovoltaic panel groove 9, wherein a second photovoltaic panel groove 10 is opened on the bottom of the first photovoltaic panel groove 9, and the second There is a third photovoltaic panel groove 11 on the groove bottom of the phot...

Embodiment 2

[0037] Such as figure 1 , 2 As shown in and 3, compared with embodiment 1, this embodiment optimizes the guide rail, which is composed of two mutually parallel rails 14; there are two groups of rotating shaft grooves 7, and they are arranged in parallel on the bottom surface of the photovoltaic panel group placement groove body 6; Each track 14 is provided with two pulleys 5, and the distance between the two pulleys 5 is less than the length of the track 14. In this embodiment, the two tracks 14 can more stably support the photovoltaic panel group placement tank 6, and Each track 14 is provided with two pulleys 5 to further stabilize the movement of the photovoltaic panel group placement tank 6 on the track 14 .

Embodiment 3

[0039] Such as figure 2 As shown, compared with Embodiment 2, this embodiment optimizes the guide rails. Along the pushing direction of the photovoltaic panel group placement tank 6, the ends of the rails 14 are all provided with stoppers 15. In this embodiment, the stoppers 15 It can prevent the installation tank body 6 of the photovoltaic panel group from being pushed down from the track 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com