Rare-earth material liquid oil removal device convenient to clean

A rare earth material liquid, convenient cleaning technology, applied in the direction of improving process efficiency, can solve problems such as troublesome cleaning of degreasing devices, and achieve the effects of easy cleaning, maintenance and repair, convenient operation, and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

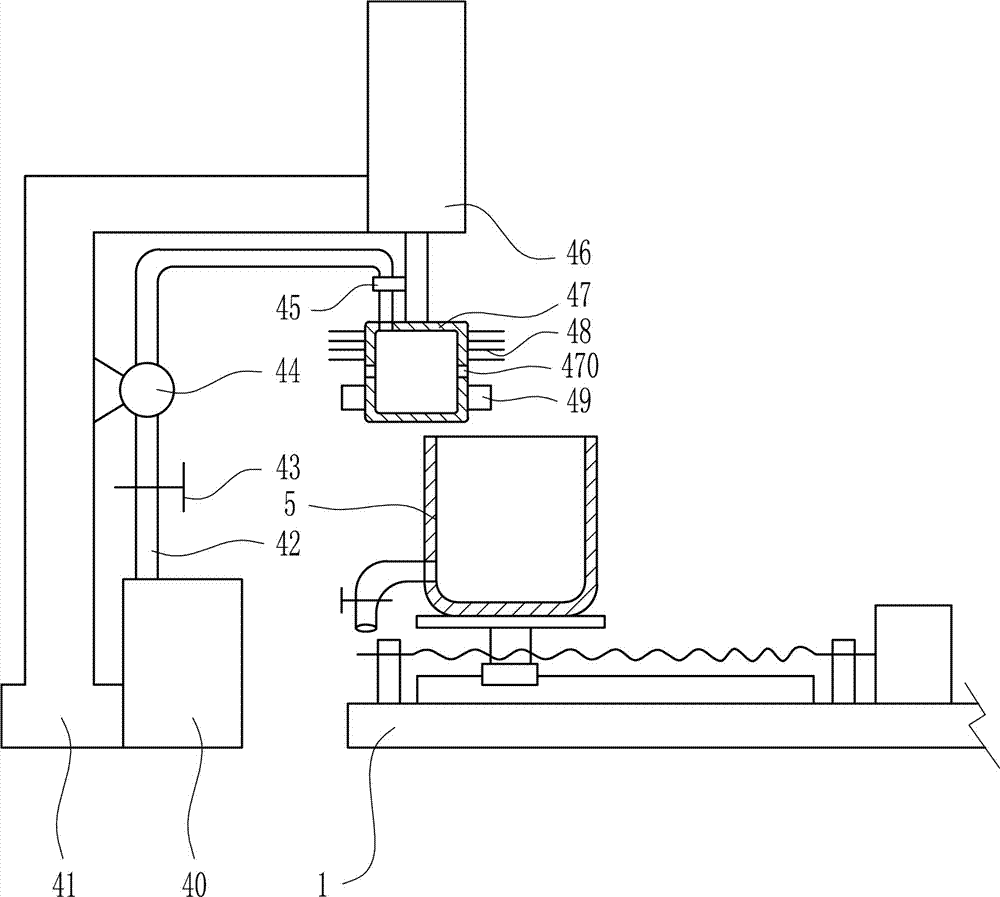

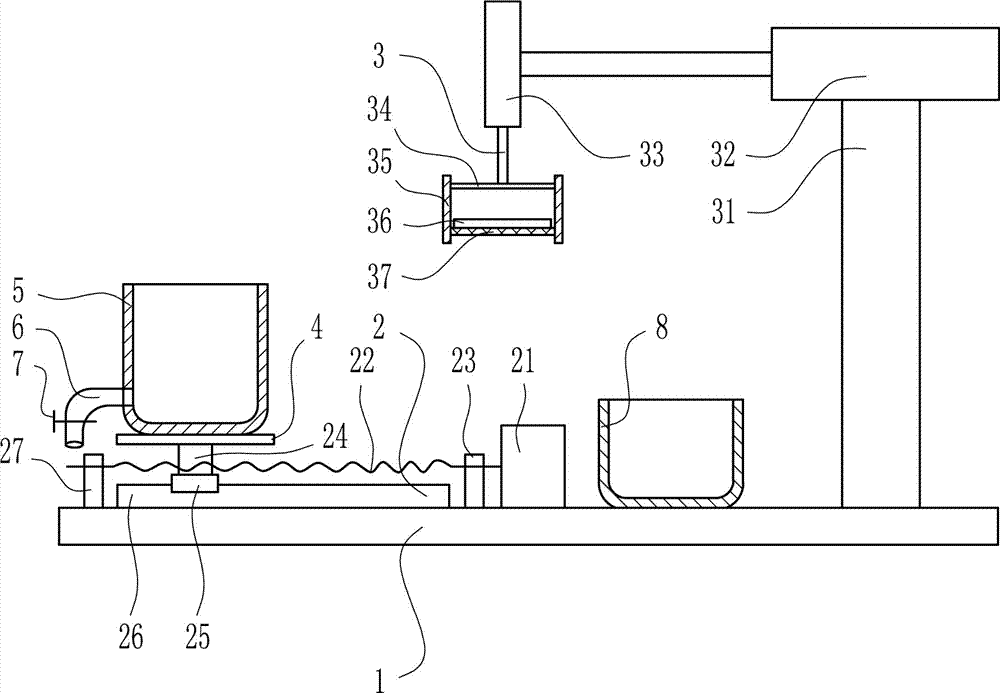

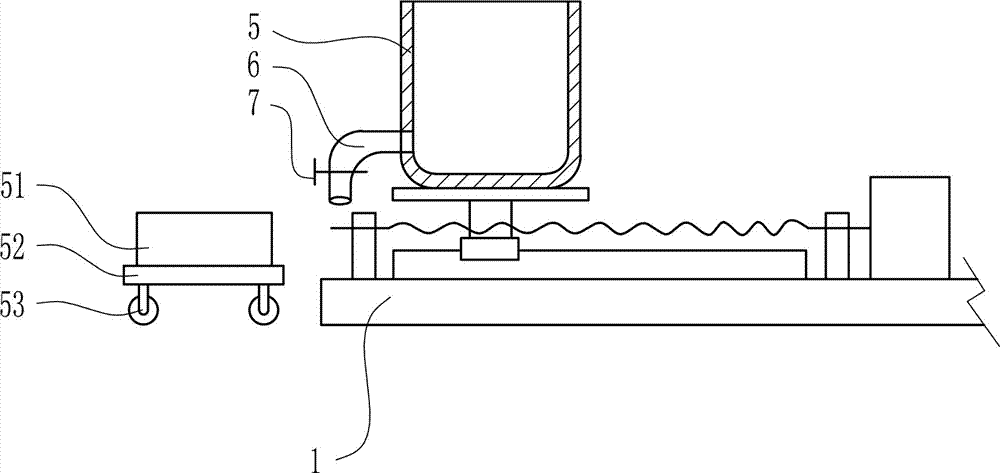

[0027] A convenient cleaning type rare earth material liquid degreasing device, such as Figure 1-3 As shown, it includes a base 1, a left and right moving device 2, an up and down oil suction device 3, a fixed plate 4, an oil removal cylinder 5, a discharge liquid pipe 6, a discharge valve 7 and a cleaning cylinder 8; Device 2, a fixed plate 4 and an oil removal cylinder 5 are arranged between the left and right moving device 2 and the up and down oil suction device 3, the bottom of the oil removal cylinder 5 is connected to the top of the fixed plate 4 by welding, and the fixed plate 4 is arranged on the left and right moving device 2, the upper and lower oil suction devices 3 are arranged above the deoiling cylinder 5, the right end of the discharge liquid pipe 6 is connected to the lower part of the left side wall of the deoiling cylinder 5 by welding, and the discharge liquid pipe 6 communicates with the deoiling cylinder 5, A discharge valve 7 is installed on the dischar...

Embodiment 2

[0029] A convenient cleaning type rare earth material liquid degreasing device, such as Figure 1-3 As shown, it includes a base 1, a left and right moving device 2, an up and down oil suction device 3, a fixed plate 4, an oil removal cylinder 5, a discharge liquid pipe 6, a discharge valve 7 and a cleaning cylinder 8; Device 2, a fixed plate 4 and an oil removal cylinder 5 are arranged between the left and right moving device 2 and the up and down oil suction device 3, the bottom of the oil removal cylinder 5 is connected to the top of the fixed plate 4 by welding, and the fixed plate 4 is arranged on the left and right moving device 2, the upper and lower oil suction devices 3 are arranged above the deoiling cylinder 5, the right end of the discharge liquid pipe 6 is connected to the lower part of the left side wall of the deoiling cylinder 5 by welding, and the discharge liquid pipe 6 communicates with the deoiling cylinder 5, A discharge valve 7 is installed on the dischar...

Embodiment 3

[0032] A convenient cleaning type rare earth material liquid degreasing device, such as Figure 1-3 As shown, it includes a base 1, a left and right moving device 2, an up and down oil suction device 3, a fixed plate 4, an oil removal cylinder 5, a discharge liquid pipe 6, a discharge valve 7 and a cleaning cylinder 8; Device 2, a fixed plate 4 and an oil removal cylinder 5 are arranged between the left and right moving device 2 and the up and down oil suction device 3, the bottom of the oil removal cylinder 5 is connected to the top of the fixed plate 4 by welding, and the fixed plate 4 is arranged on the left and right moving device 2, the upper and lower oil suction devices 3 are arranged above the deoiling cylinder 5, the right end of the discharge liquid pipe 6 is connected to the lower part of the left side wall of the deoiling cylinder 5 by welding, and the discharge liquid pipe 6 communicates with the deoiling cylinder 5, A discharge valve 7 is installed on the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com