Mixed type spinning plate and manufacturing technology thereof

A spinneret and hybrid technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of excessive fluffiness, poor hand feeling, low gloss, etc., to improve the overall performance and improve the connection Effects of fastness, good hand and gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

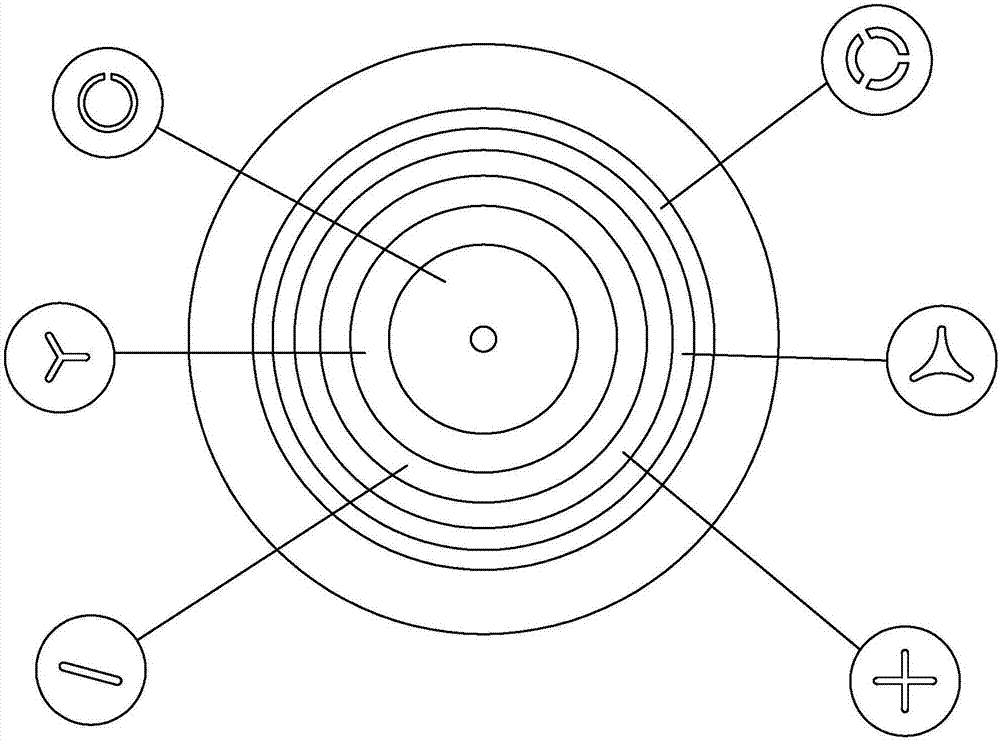

[0038] A hybrid spinneret, refer to figure 1 , including 1000 special-shaped spinneret holes set in concentric circles, the area difference between the concentric circles is equal, the density of the spinneret holes in each area is the same, and the center of the spinneret is provided with circular spinneret holes and triangular spinneret holes in turn. hole, one-shaped spinneret hole, cross-shaped spinneret hole, three-lobed spinneret hole and three-C-shaped spinneret hole, the structural parameters of the spinneret hole are as follows:

[0039] The three-lobed spinneret hole is composed of three blades, the angle between the two blades is 120°, the angle between the two blades is connected by an arc, the radius of the arc is 0.04mm, and the ratio of the blade diameter to the blade width is 2.2 ;

[0040] The three C-shaped spinneret holes are composed of three C-shaped rings, the angle between the two rings is 120°C, the gap between the rings is 0.03mm, the diameter of the ...

Embodiment 2

[0050] A hybrid spinneret, refer to figure 1 , including 1500 special-shaped spinneret holes set in concentric circles, the area difference between the concentric circles is equal, the density of the spinneret holes in each area is the same, and the center of the spinneret is provided with circular spinneret holes and triangular spinneret holes in turn. hole, one-shaped spinneret hole, cross-shaped spinneret hole, three-lobed spinneret hole and three-C-shaped spinneret hole, the structural parameters of the spinneret hole are as follows:

[0051] The three-lobed spinneret is composed of three blades, the angle between the two blades is 120°, the angle between the two blades is connected by an arc, the radius of the arc is 0.06mm, and the ratio of the blade diameter to the blade width is 2.7 ;

[0052] The three C-shaped spinneret holes are composed of three C-shaped rings, the angle between the two rings is 120°C, the gap between the rings is 0.05mm, the diameter of the outer...

Embodiment 3

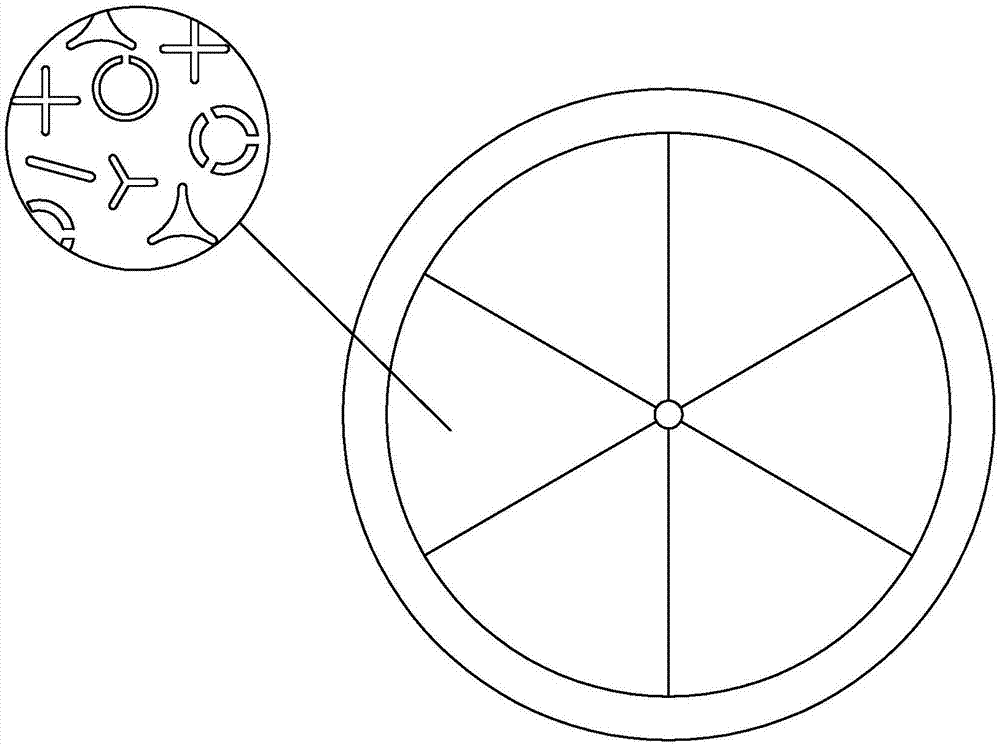

[0062] A hybrid spinneret, refer to figure 2 , including 1,200 special-shaped spinneret holes set in concentric circles, the spinneret plate is divided into 6 lobes and 60° fan-shaped, and there are an equal number of three-lobed spinneret holes and three C-shaped spinneret holes randomly distributed in each fan-shaped area , triangular spinneret hole, straight spinneret hole, circular spinneret hole and cross-shaped spinneret hole, the structural parameters of the spinneret hole are as follows:

[0063] The three-lobed spinneret hole is composed of three blades, the angle between the two blades is 120°, the angle between the two blades is connected by an arc, the radius of the arc is 0.08mm, and the ratio of the diameter of the blade to the width of the blade is 3.2 ;

[0064] The three C-shaped spinneret holes are composed of three C-shaped rings, the angle between the two rings is 120°C, the gap between the rings is 0.08mm, the diameter of the outer circle is between 0.54...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com