Rapid manhole cover repairing method

A fast and well-covering technology, applied to waterway systems, drainage structures, water supply devices, etc., can solve problems such as easy damage and deformation, affecting drainage well maintenance efficiency, and slow cement molding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

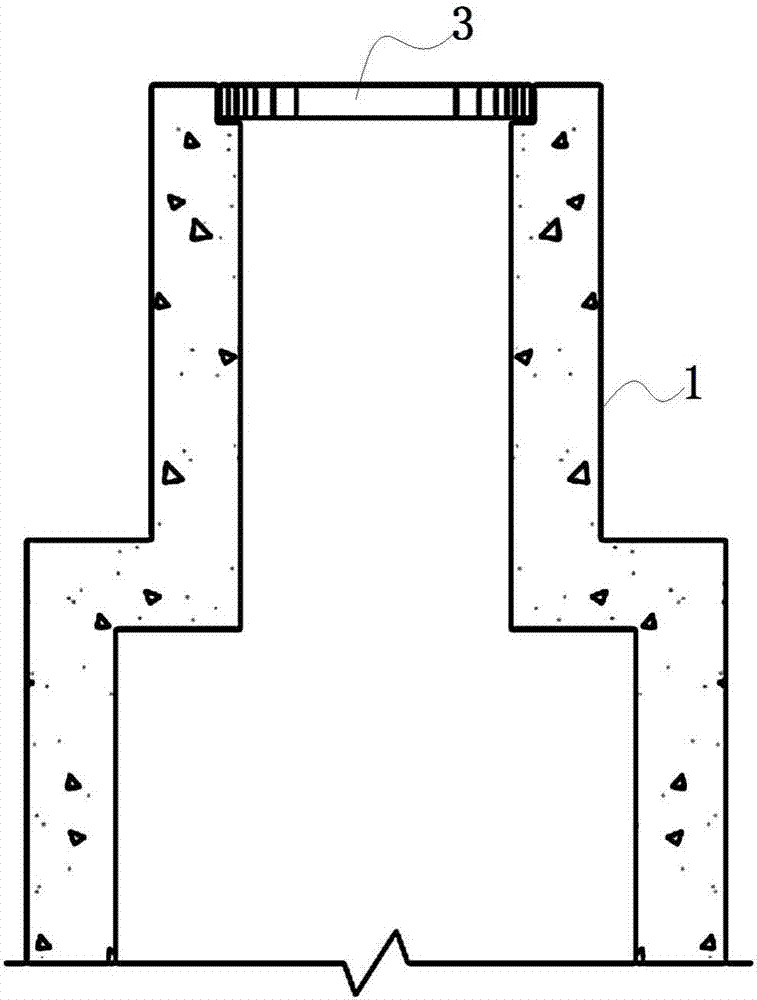

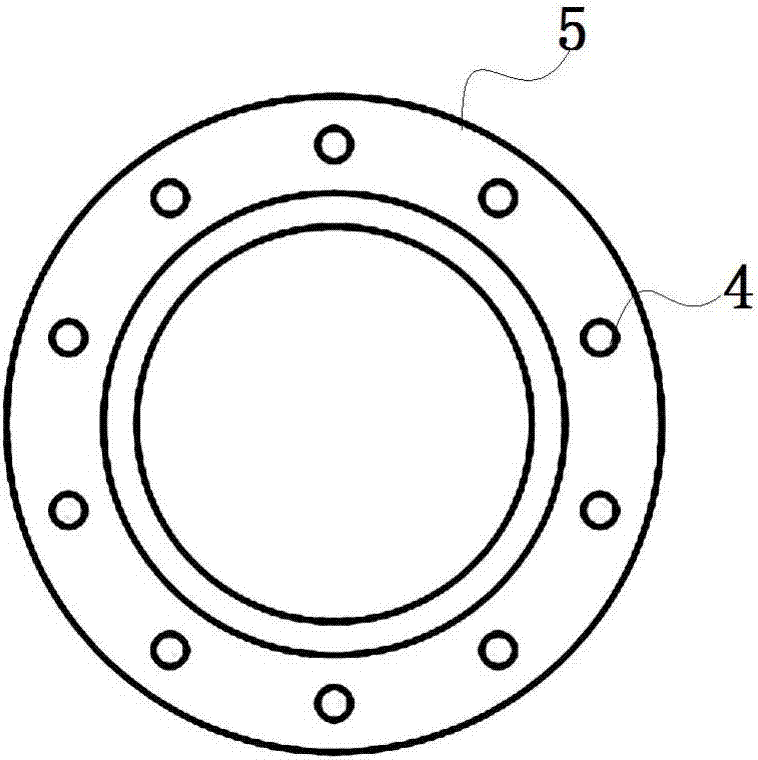

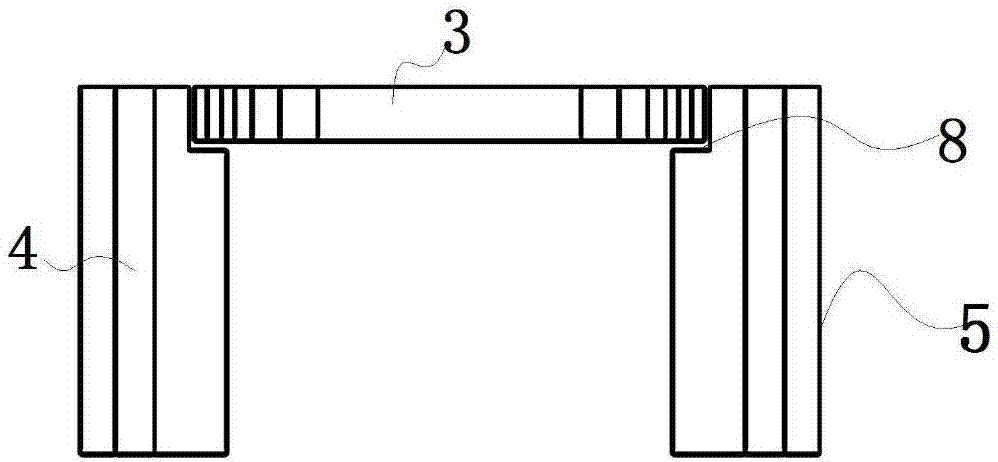

[0020] Such as Figure 1-6 As shown, the specific embodiment of the present invention is a quick repair method for manhole cover. Such as image 3 , the prefabricated wellbore 5 is made by pouring in advance, which is a circular cylinder, and a plurality of grouting through holes 4 are evenly distributed on the wall of the prefabricated wellbore 5, and nuts 9 are fixedly embedded in part of the grouting throughholes 4; specifically The operation steps are as follows:

[0021] In the first step, as shown in Figure 4, the concrete on the upper part of the inner wall of the pre-repaired well body 2 is circularly cut by the cutting device 1. The axial length of the cut part is greater than the height of the prefabricated well shaft 5, and the well body 2 after cutting forms a horizontal section. Then remove the excised part;

[0022] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com