Stainless steel valve insulating jacket

A thermal insulation cover, stainless steel technology, applied in heat preservation, pipeline protection, pipeline protection through heat insulation, etc., can solve the problems of high temperature valve insulation cover not energy saving, flange seal easy to leak, inconvenient inspection and maintenance, etc., to achieve long-term high efficiency, energy saving, Quick assembly and disassembly, the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

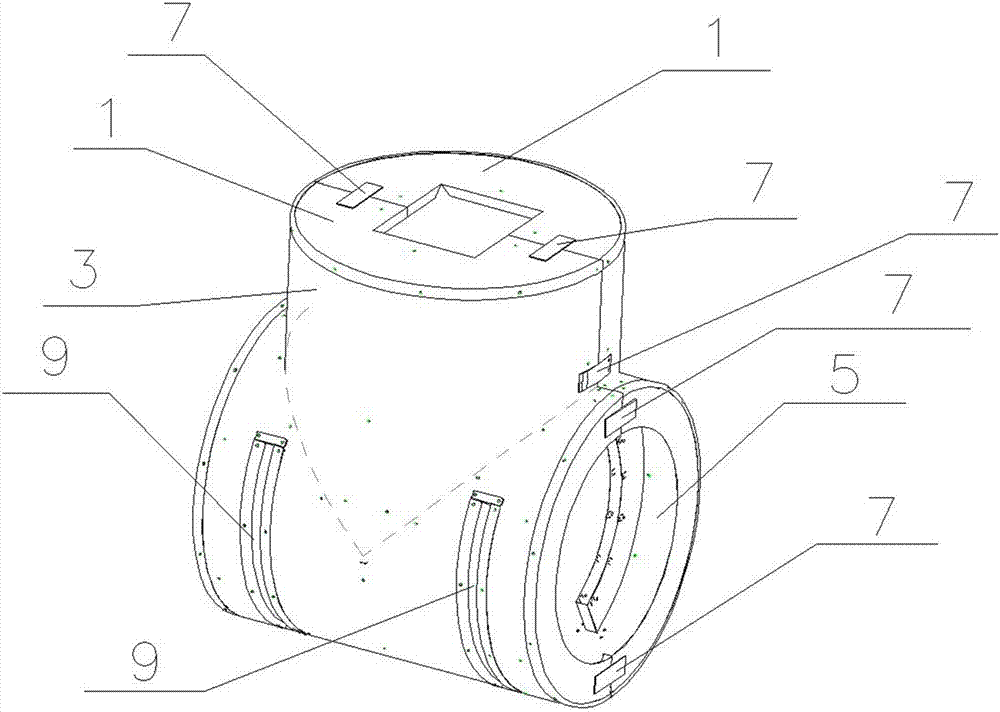

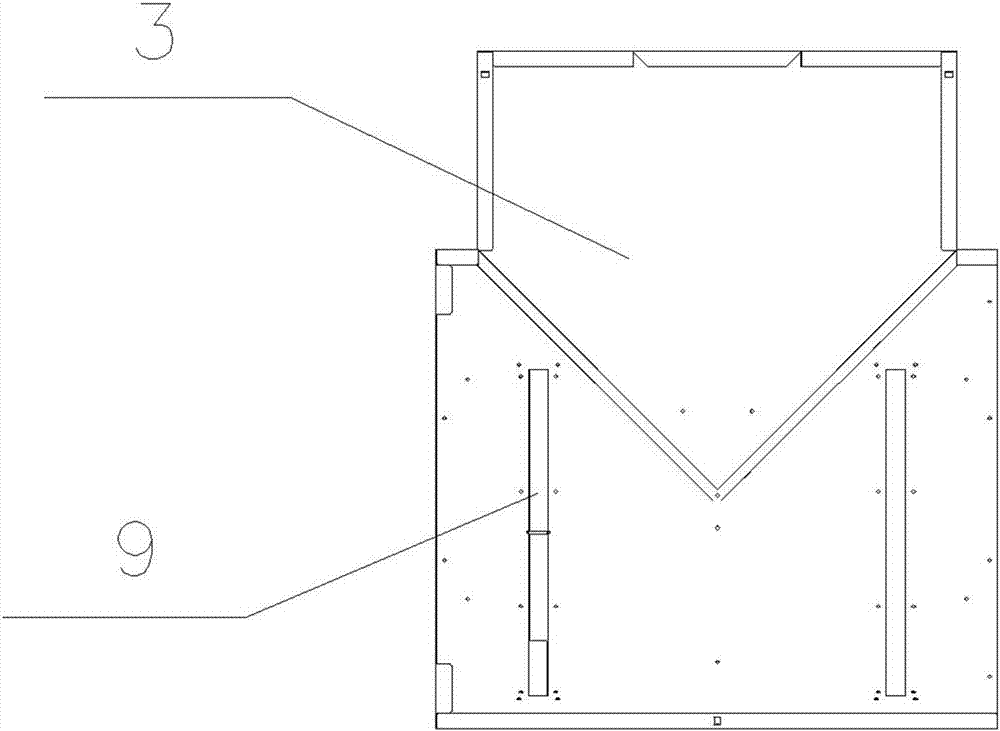

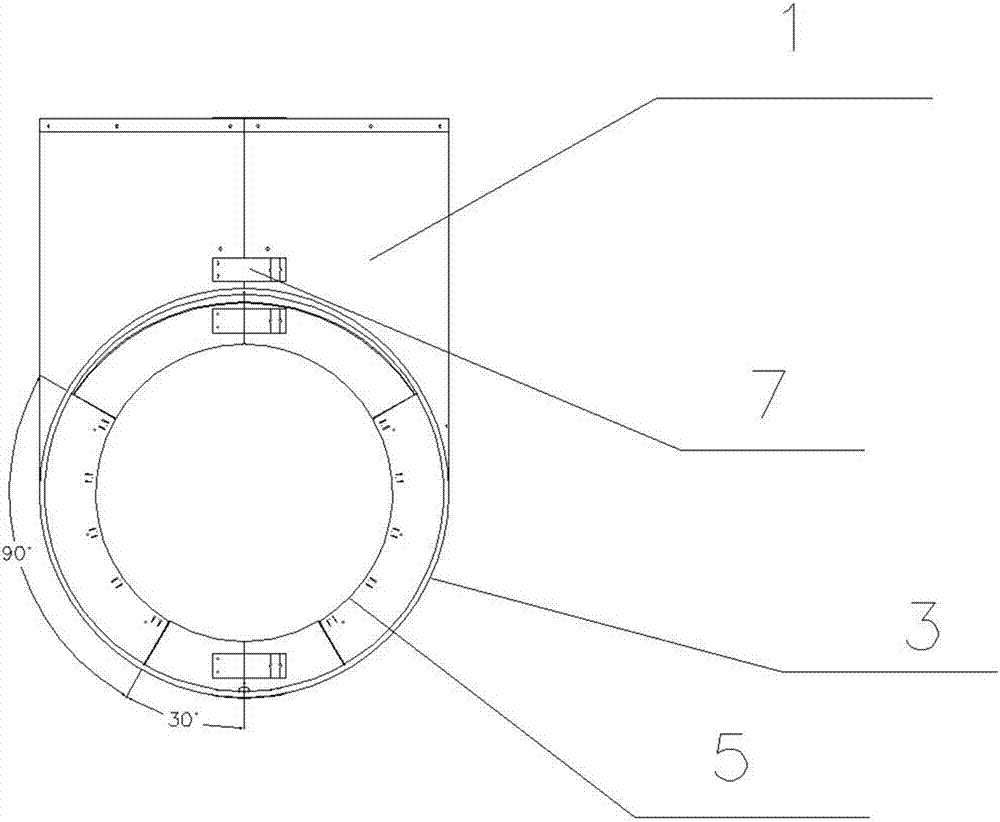

[0022] see Figure 1 to Figure 3 , a stainless steel valve insulation sleeve, including two insulation sleeve splits 1 and eight fasteners 7. The two thermal insulation cover splits 1 are sequentially connected by eight fasteners 7 in a fastening manner.

[0023] Wherein, each insulation cover split 1 includes a stainless steel shell 3 and an inner lining insulation layer 5 . The inner liner insulation layer 5 is connected with the stainless steel shell 3 to form an organic whole, and the whole structure is manufactured in a prefabrication factory. Two heat conduction grooves 9 are all provided on each insulating cover split body 1 .

[0024] Advantage of the present invention and beneficial effect:

[0025] 1. The present invention achieves a long-term and high-efficiency energy-saving effect through the reasonable matching of the inner lining insulation layer 5 and the stainless steel shell 3. Compared with the conventional insulation cover, the energy-saving effect reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com