Method and equipment for producing corn granules from corn flour

A cornmeal and corn technology, which is applied in food forming, food preservation, food science and other directions, can solve the problems of inability to meet the needs of taste and taste buds, and achieve the effect of enriching eating methods, satisfying the needs of taste buds, and retaining nutritional elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

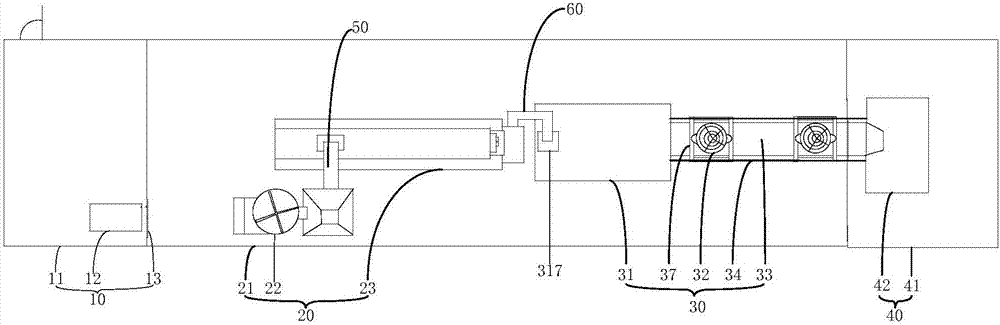

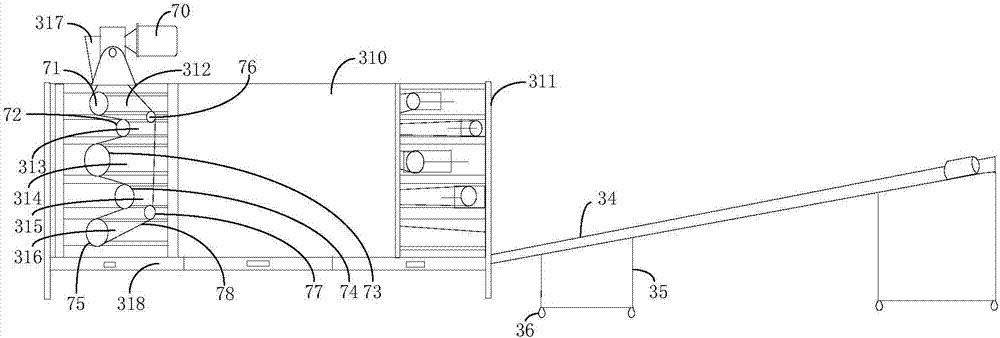

[0024] The method for producing corn grains from cornmeal comprises the following steps: preparing cornmeal for use, mixing the cornmeal with water to form a flocculent structure, then putting the cornflour with the flocculent structure into an extruder to extrude the corngrains, and then The corn grains are dried, cooled rapidly after drying, and packaged after cooling.

[0025] When using an extruder to extrude corn kernels, the puffing temperature is set to five zones. When puffing, it first passes through the first zone for puffing at a temperature of 48 degrees Celsius to 52 degrees Celsius, and then passes through the second zone for puffing. The puffing temperature is 98 degrees Celsius ~102 degrees Celsius, then enter the third zone, the puffing temperature of the third zone is 198 degrees Celsius ~ 122 degrees Celsius, then enter the fourth zone for puffing, the puffing temperature is 148 degrees Celsius ~ 152 degrees Celsius, and finally enter the fifth zone, the fift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com