Process and double-roller rolling machine for processing fluffy mushroom of flammulina velutipes

A processing technology and technology of Flammulina velutipes, which is applied in the field of food processing, can solve the problems of inability to meet the needs of different consumers' tastes, single eating method, etc., and achieve the effect of enriching eating methods and being easy to eat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

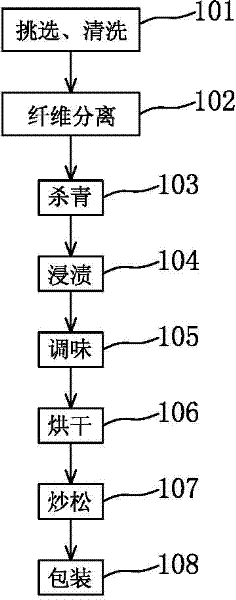

[0025] see figure 1 , is a flow chart of the steps of the processing technology of Flammulina velutipes mushroom pine of the present invention.

[0026] The processing technology of this Flammulina velutipes mushroom pine, comprises the following steps:

[0027] Step 101, selecting and cleaning: selecting fresh and non-deteriorated Flammulina velutipes to remove the non-edible part of the culture medium, putting the Flammulina velutipes into water to clean them, and filtering to clear water.

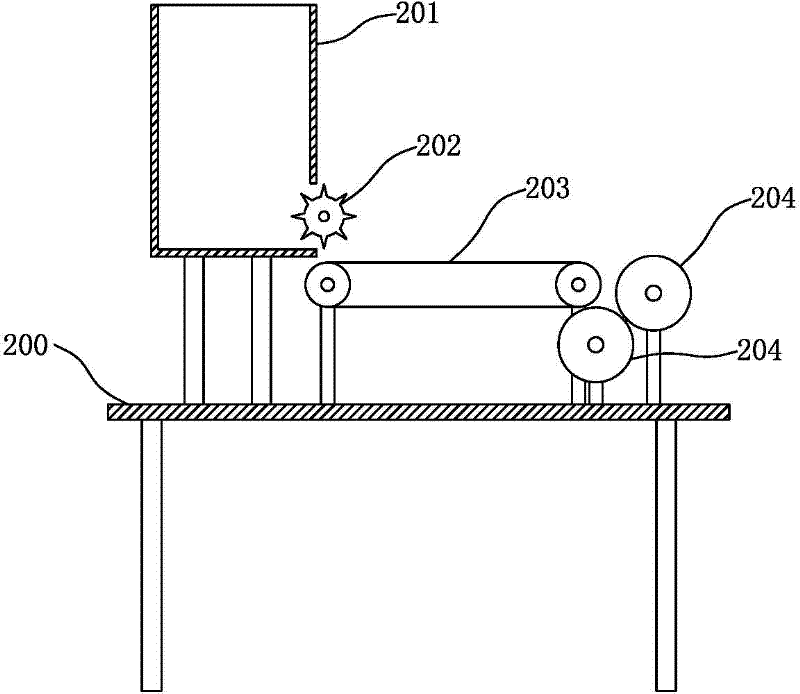

[0028] Step 102, fiber separation: put the Flammulina velutipes into a double-roller compactor, and after rolling, separate the fiber part of the Flammulina velutipes.

[0029] Step 103, finishing: take citric acid to prepare a citric acid solution, and boil it, put the detached enoki mushrooms into the boiling citric acid solution for 0.5-15 minutes and cook until tasty, then filter out the citric acid solution, and place the enoki mushrooms at room temperature Cool in water, after co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com