Improved princess-cut diamond processing method

A processing method and improved technology, applied in clothing, applications, jewelry, etc., can solve the problems of fire that affects refraction, large countertops, and monotony, achieve a strong sense of hierarchy, improve light refraction, and improve brightness and fire. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] A processing method for an improved princess cut diamond, comprising the steps of:

[0038] 1) Refer to figure 1 with figure 2 Cut the table top. That is, according to the design requirements, the tabletop 1 is cut out on the rough diamond 2. Because the surface of the tabletop 1 is irregular, the tabletop that is cut out is also an irregular square (see figure 2 );

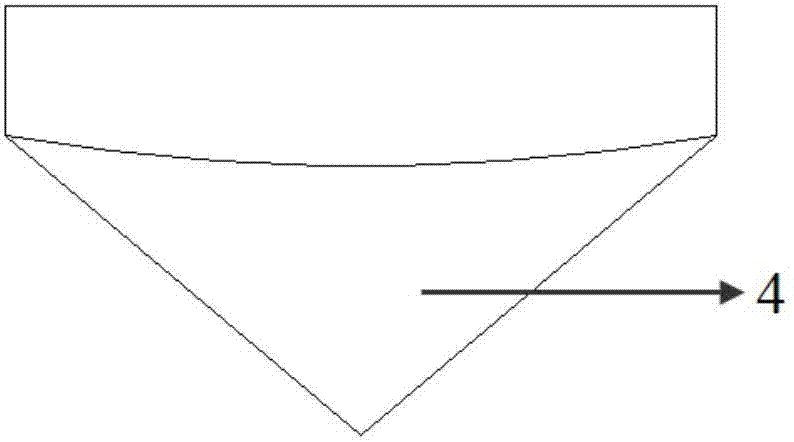

[0039] 2) Grinding the square. Grind the four sides of the square towards the waist respectively, and grind out the square cone used to form the waist (see image 3 with Figure 4 ); then sand the waist 3. The waist height accounts for 15% of the total height of the quadrangle.

[0040] 3) Grinding the pavilion (see Figure 5-9 ). Grind the triangular facet 4 parallel to the waist at 55 degrees, polish the waist thickness to account for 10% of the total height of the square, and make the four waist lines even; A large facet 5. After the grinding is completed, looking up from the bottom to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com