Device for refitting horizontal lathe to complete partial functions of horizontal milling machine

A horizontal lathe and horizontal technology are applied in the field of devices for refitting a horizontal lathe to complete part of the functions of a horizontal milling machine, which can solve the problems of no milling machine, incomplete equipment, high price, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

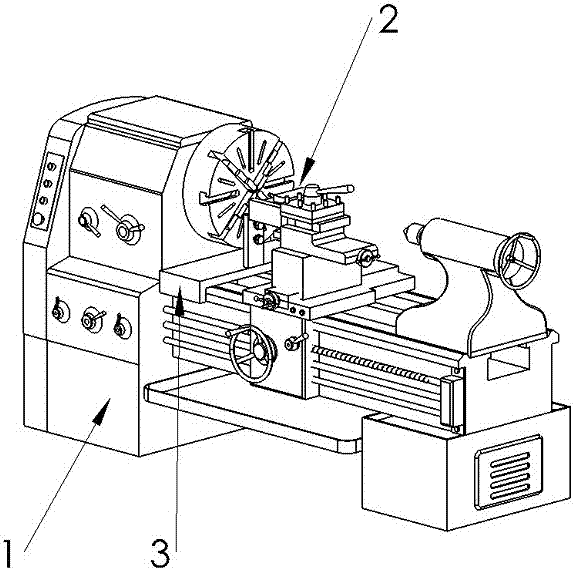

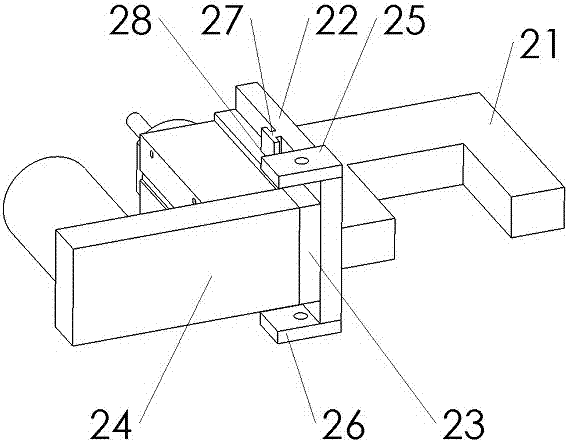

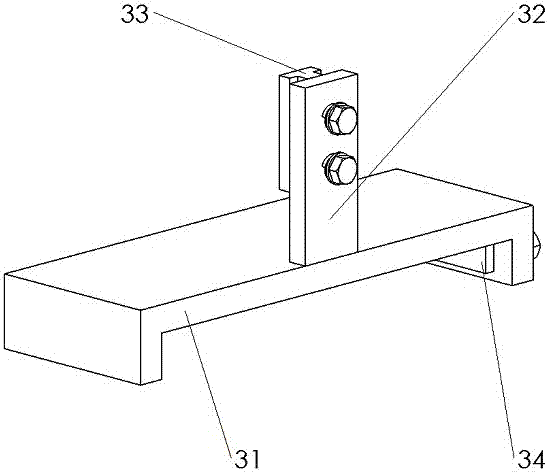

[0015] Such as figure 1 , figure 2 , image 3 As shown, a device for refitting a horizontal lathe to complete part of the functions of a horizontal milling machine, including a lathe body 1, a milling cutter module 2 is installed at the tool holder of the lathe body 1, and the milling cutter module 2 provides milling power. After completing the milling action, a fixed module 3 is provided under the lathe fixture of the lathe body 1, and the fixed module 3 is located on the top of the lathe bed, and the fixed module 3 fixes the lathe fixture to prevent the fixture from shifting during milling. The milling cutter module 2 includes a splint 21, the left end of the splint 21 is provided with a sliding seat 22, the left end of the sliding seat 22 is provided with a power head mounting plate 23, and the left end of the power head mounting plate 23 is equipped with a milli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com