Crystal raw material and unmanned loading machine thereof

A technology for raw materials and crystals, applied in the field of crystal raw materials and their unmanned feeding machines, can solve the problems of large consumption of human resources, high missed detection rate, induction errors, etc., to reduce labor costs, improve production efficiency, and identify accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below through specific embodiments and accompanying drawings.

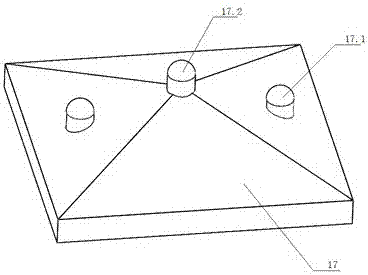

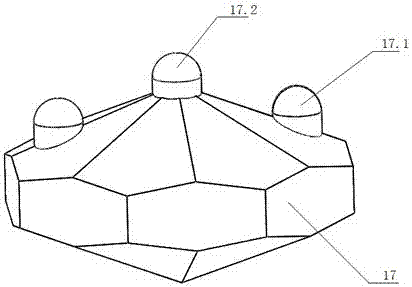

[0026] The implementation method is as follows: Figure 1-2 Shown, be respectively the crystal raw material of square bead and octagonal bead, comprise the blank body of crystal raw material 17 with certain shape, wherein one side of crystal raw material 17 is provided with two projections 17.1, middle position is provided with central positioning block 17.2, three are arranged in a straight line. Wherein, the central positioning block 17.2 has a width of 1 mm to 10 mm and a height of 1 mm to 10 mm.

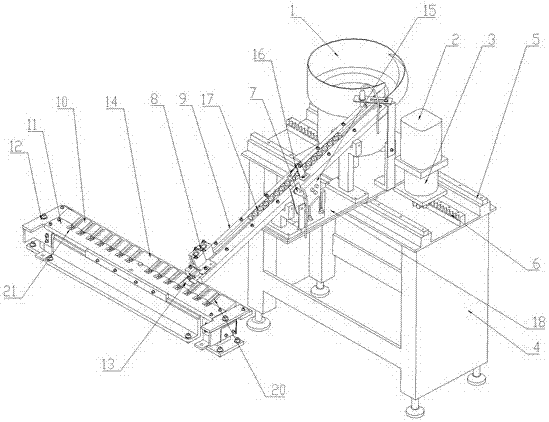

[0027] Such as Figure 3-5 Shown, a kind of unmanned feeding machine of crystal raw material, is used for the feeding of above-mentioned crystal raw material 17 before entering grinding machine, comprises frame 4, is provided with shifting mechanism on frame 4, and is installed on the shifting mechanism There is a vibrating disc sorting machine 1. According to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com