Keyboard clamping mechanism based on double effects of pressure and suction

A dual-action, clamping mechanism technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of products being crushed, unable to ensure the pressure, and occupying a large space, so as to achieve convenient operation and easy maintenance , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

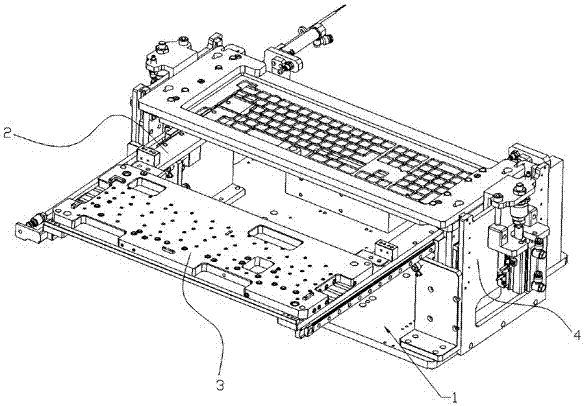

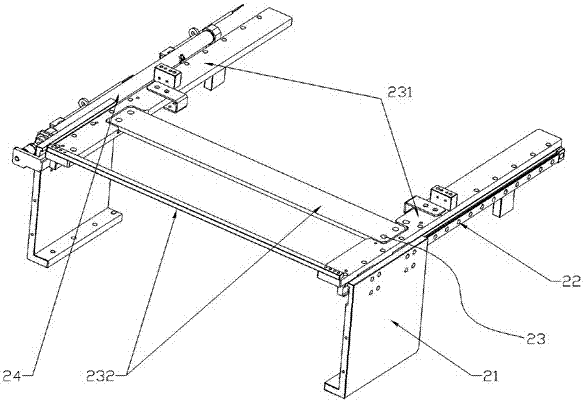

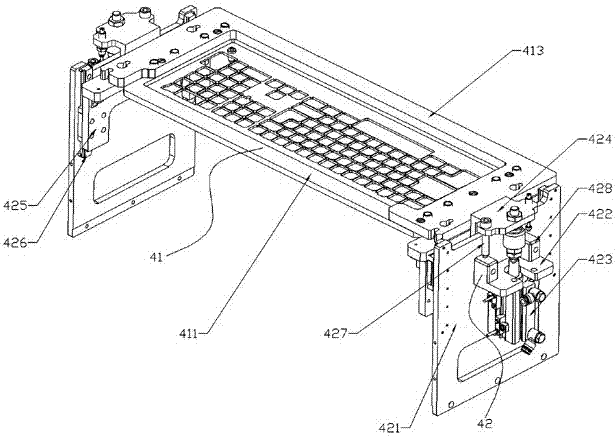

[0022] Such as Figure 1 to Figure 6 As shown, in this embodiment, the present invention includes a base plate 1, an in-out mechanism 2, a vacuum adsorption carrying mechanism 3 and a platen pressing mechanism 4, the in-out mechanism 2 is fixedly installed on the base plate 1, and the vacuum adsorption carrying mechanism 3 Slidingly fit with the entry and exit mechanism 2, the pressure plate mechanism 4 is arranged above the entry and exit mechanism 2, the entry and exit mechanism 2, the vacuum adsorption carrying mechanism 3 and the pressure plate mechanism 4 are all connected with the external MCU control module electrical connection.

[0023] This design combines two methods of clamping plate fixing and vacuum adsorption fixing to clamp the product, which provides a reliable fixing method for high-precision testing of the product; moreover, the invention has a compact, light, simple structure, convenient operation, and easy maintenance.

[0024] In this embodiment, the ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com