Repairing tool and method for adjusting valve with valve element being provided with C-shaped ring for sealing assisting

A technology of regulating valve and valve core, which is used in manufacturing tools, abrasive surface regulating devices, metal processing equipment, etc., can solve the problem that the repair work of the sealing surface of the pneumatic regulating valve cannot be completed, the selection of the angle to match the grinding machine is difficult, and the coaxiality cannot be Rely on and other problems to achieve the effect of flexible and efficient repair method, reliable assembly and fixing method, and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

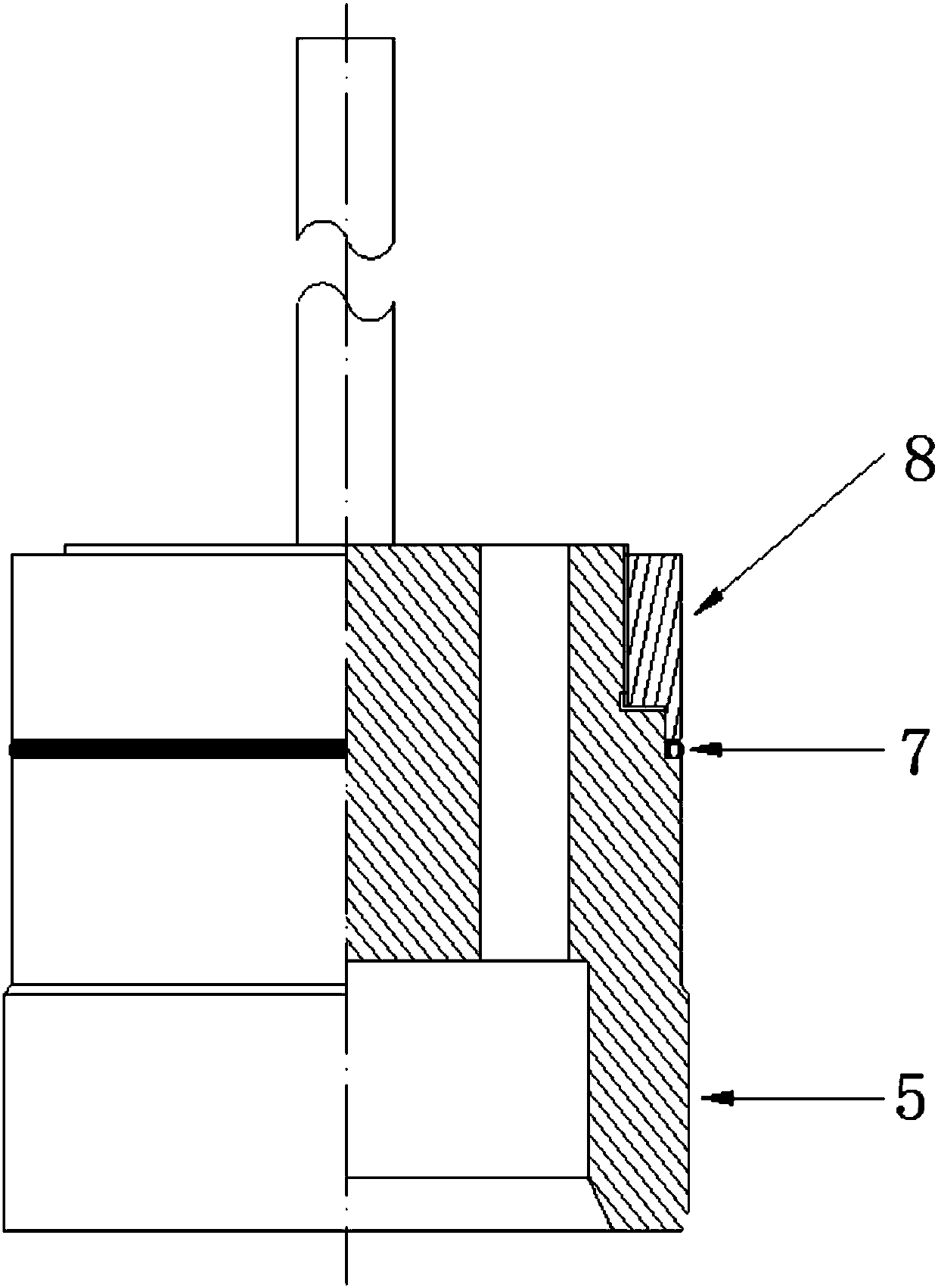

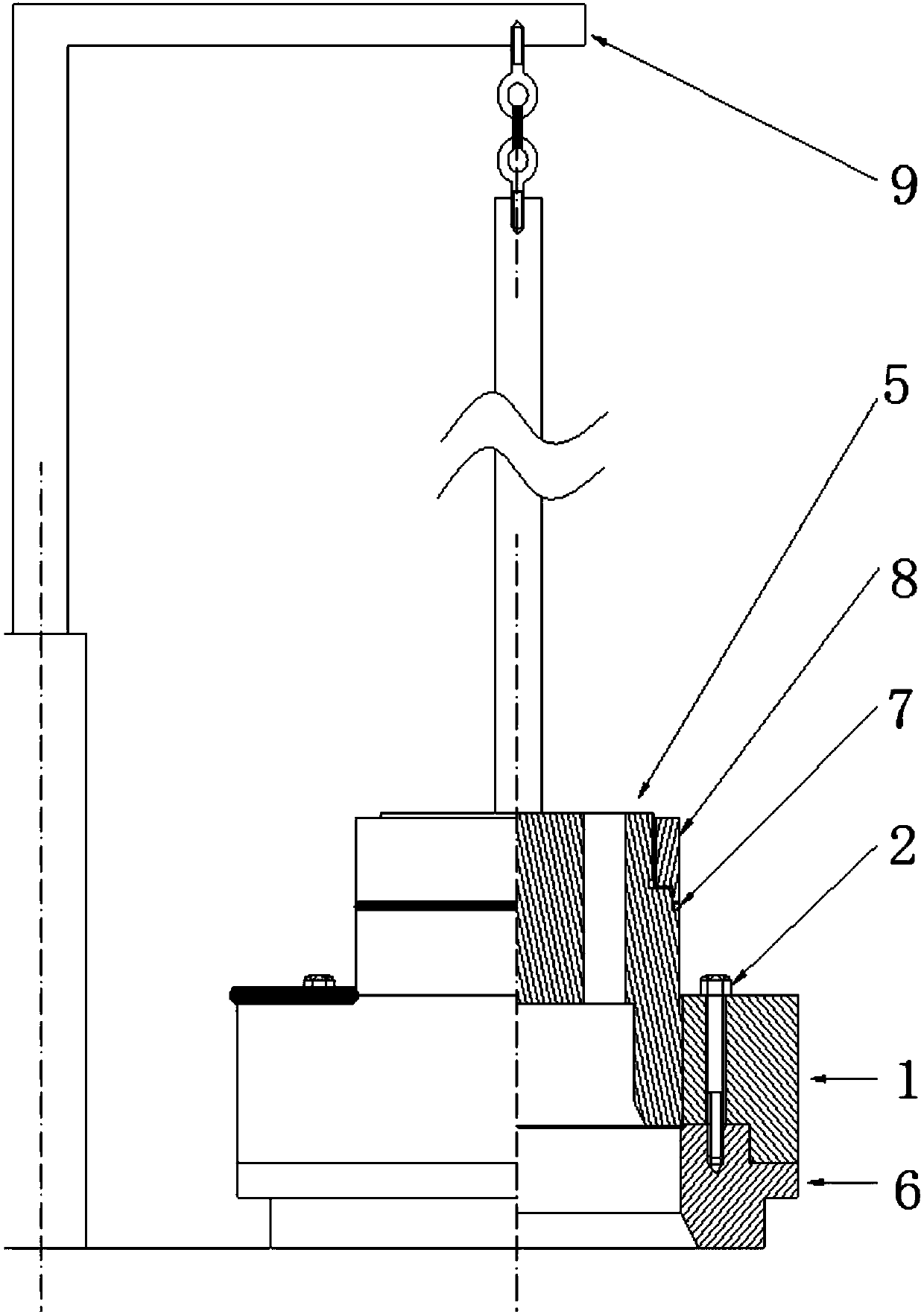

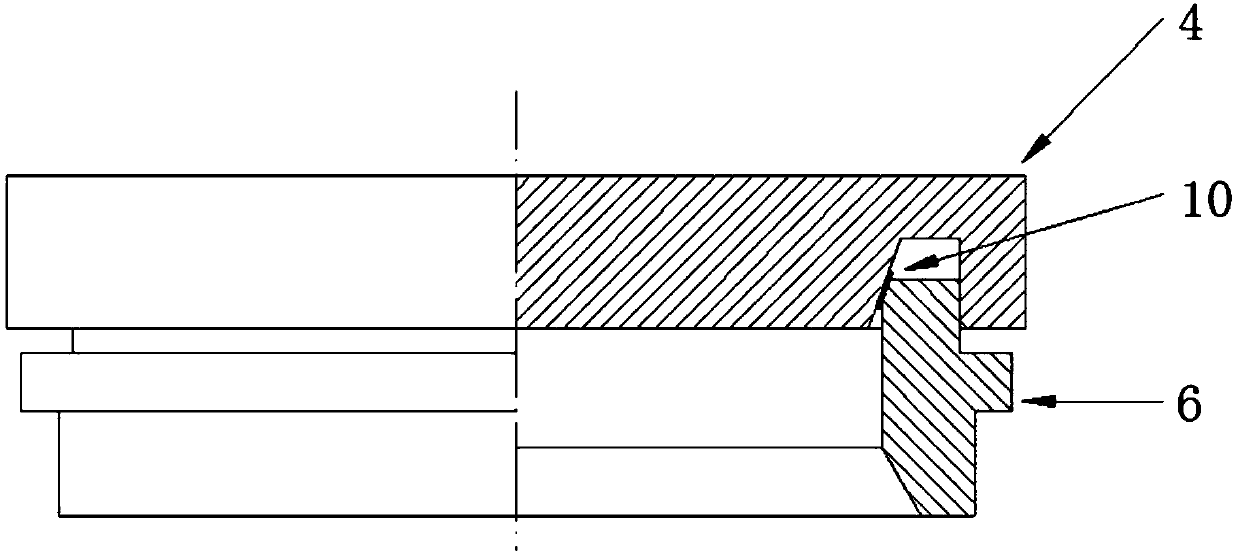

[0058] as attached figure 1 ~ attached Figure 4 As shown, the present invention provides a control valve inspection and repair device with a C-shaped sealing ring on the valve core. The device includes a guide sleeve 1, a guide sleeve fixing bolt 2, a valve core grinding mold 3, and a valve seat grinding tire Tool 4. Valve core lifting device 5. Sandpaper and other consumables for grinding.

[0059] Among them, the guide sleeve is made of polytetrafluoroethylene. The purpose of choosing non-metallic material is that if the metal material is used, there will be jamming and friction between the metals when the valve core is guided, which will cause the valve core to be damaged. The outer diameter of the guide sleeve is designed according to the diameter of the outer end surface of the valve seat, and the inner diameter is enlarged by 0.2 mm on the basis of the diameter of the outer end surface of the valve core. The lower end of the guide sleeve is made a groove strictly acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com