Steer frame of flaw detection trolley of freight heavy railways

A technology for bogies and flaw detection cars, which is applied to bogies, railway inspection cars, railway car body parts, etc., and can solve the problems of heavy labor, unsatisfactory flaw detection accuracy, and low efficiency of manual flaw detection rail flaw detection. The effect of improving the accuracy of flaw detection, improving the efficiency of flaw detection, and strong traction reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

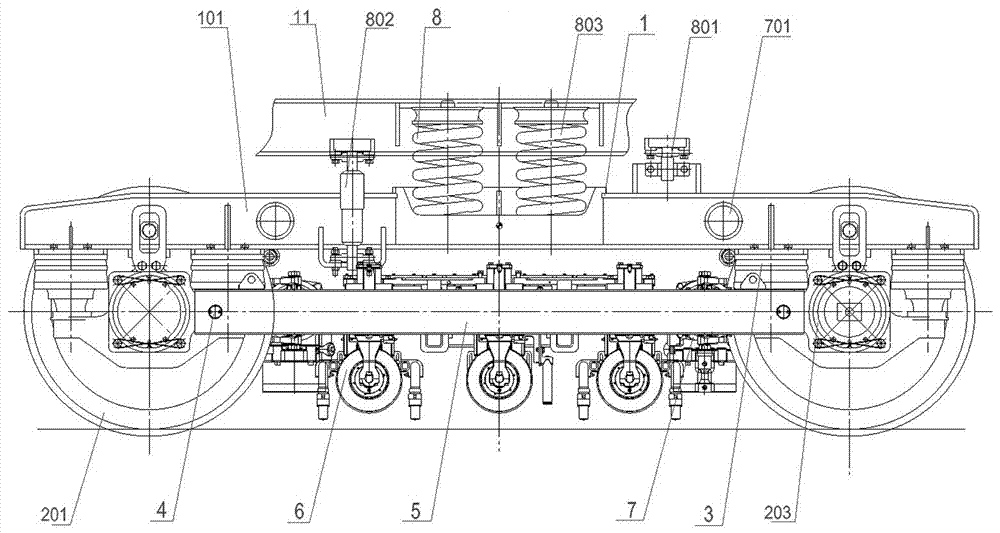

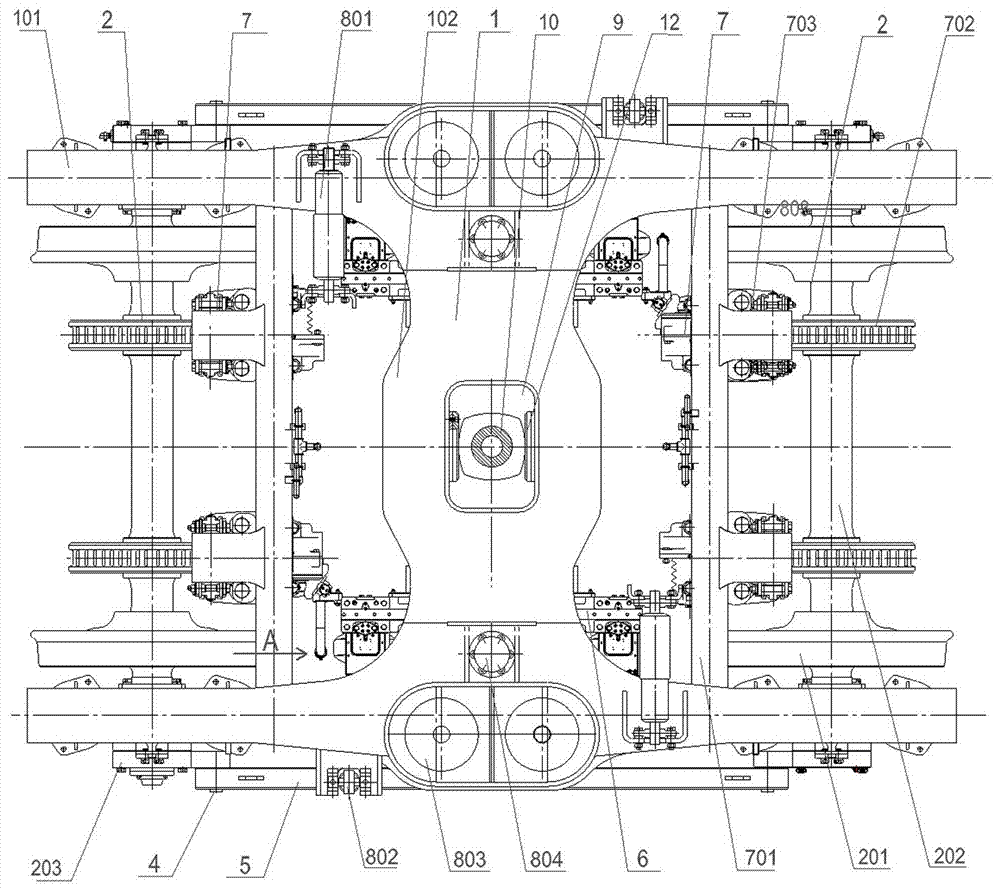

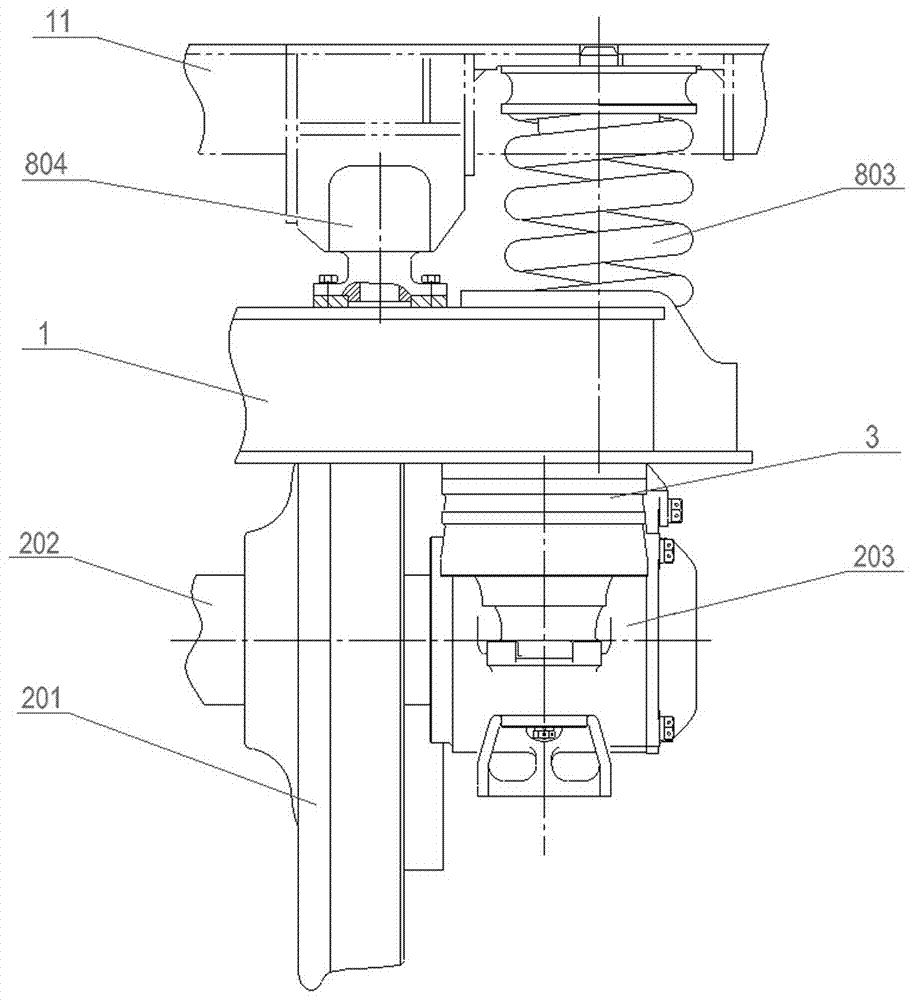

[0022] The bogie of the freight heavy-duty railway flaw detection vehicle of the present invention includes an "H"-shaped support frame 1, the support frame 1 includes frame side beams 101 and frame beams 102, and the frame beams 102 are vertically fixed between the frame side beams 101 , and the frame side beam 101 is flush with the lower bottom surface of the frame beam 102, and the lower part of the two ends of the support frame 1 is provided with a pair of scroll wheels 2, and the pair of scroll wheels includes a scroll wheel 201 and a wheel pair shaft 202, and the scroll wheel 201 is coaxially installed on the wheel-to-axle 202, and the two ends of the wheel-to-axle 202 are equipped with a wheel-to-axle box 203, and a rubber pile spring 3 is fixedly arranged between the wheel-to-axle box 203 and the bottom surface of the frame side beam 101; The outer side of the wheel-to-axle box 203 is fixedly provided with elastic fixing pins 4, and a flaw detection trolley suspension b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap