Opening and cleaning line

A technology for processing thread and cotton, which is applied in the field of processing line for cotton opening and impurity removal, which can solve problems such as low work efficiency, increased cost, waste of factory floor space and resources, and achieve the effect of improving work efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

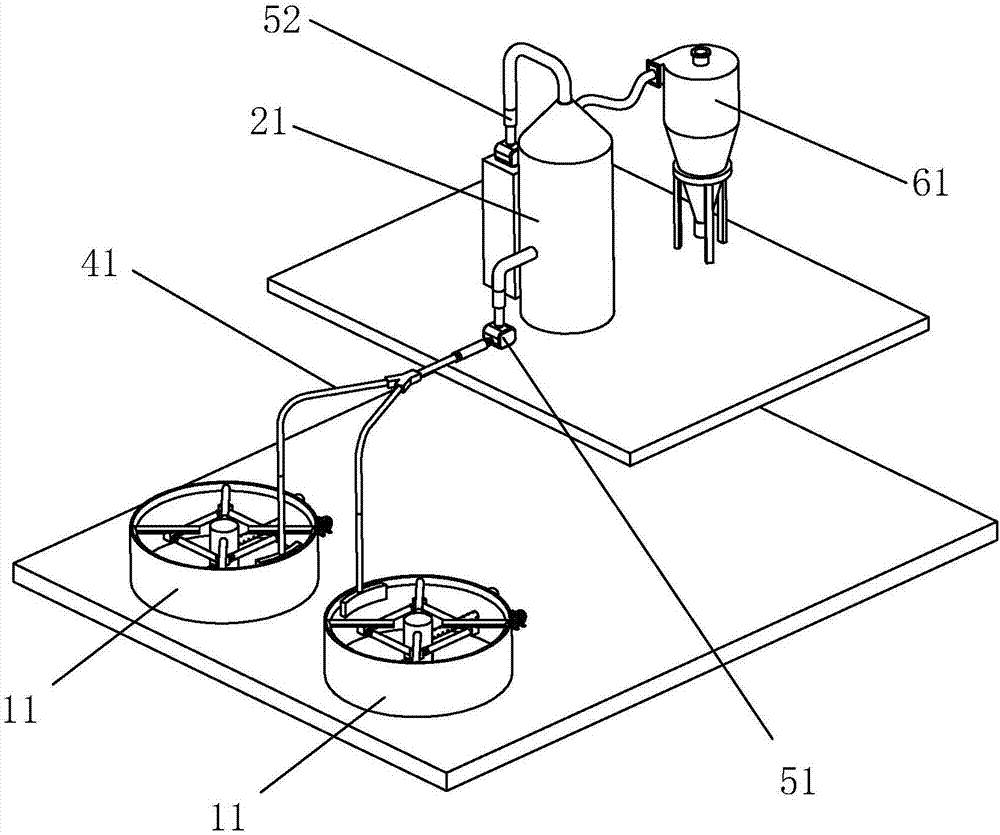

[0042] Embodiment: a kind of processing line that is used for cotton opening and impurity removal, such as figure 1 As shown, it includes a cotton opening mechanism, an impurity removal mechanism and a collection mechanism in sequence, wherein there are two cotton opening mechanisms, which are connected in parallel with the impurity removal mechanism through a Y-shaped pipe 41 .

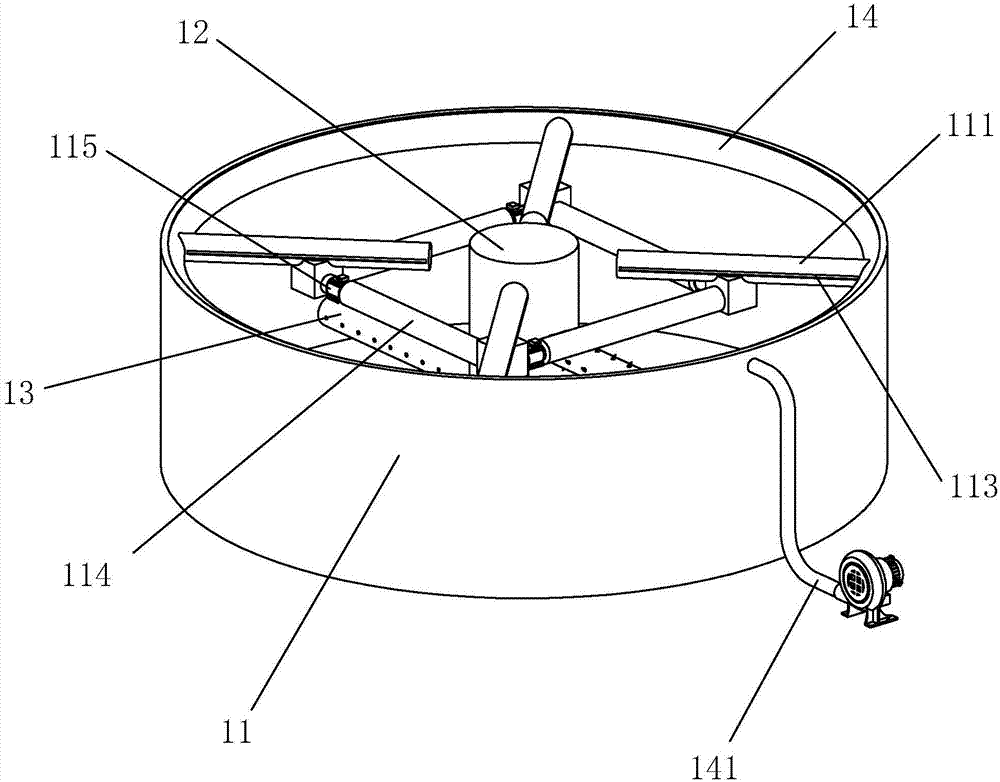

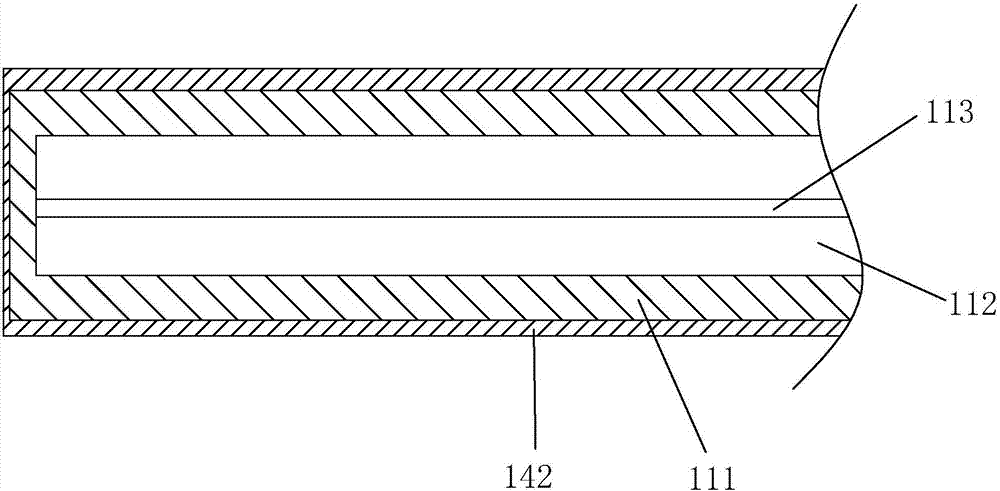

[0043] Such as image 3 and Figure 4 As shown, the cotton opening mechanism includes a storage platform 11, a worktable 12 and a first driving device for driving the rotation of the worktable 12 are arranged at the center of the storage platform 11, the worktable 12 is rotatably connected with the storage platform 11, and the inside of the worktable 12 is provided with The first driving device is the first driving motor 122, and the first driving motor 122 is welded on the bottom of the accommodation platform 11, and the workbench 12 is connected with the transmission shaft of the first driving mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com