In-pipe sludge cleaning device for sludge distribution on incinerator and garbage incinerator

An incinerator and mud cleaning technology, which is applied in the direction of incinerators, cleaning methods and appliances, dehydration/drying/concentrated sludge treatment, etc., can solve problems such as the influence of even sludge falling, and achieve the goal of avoiding sludge clogging and sustainable The effect of running and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

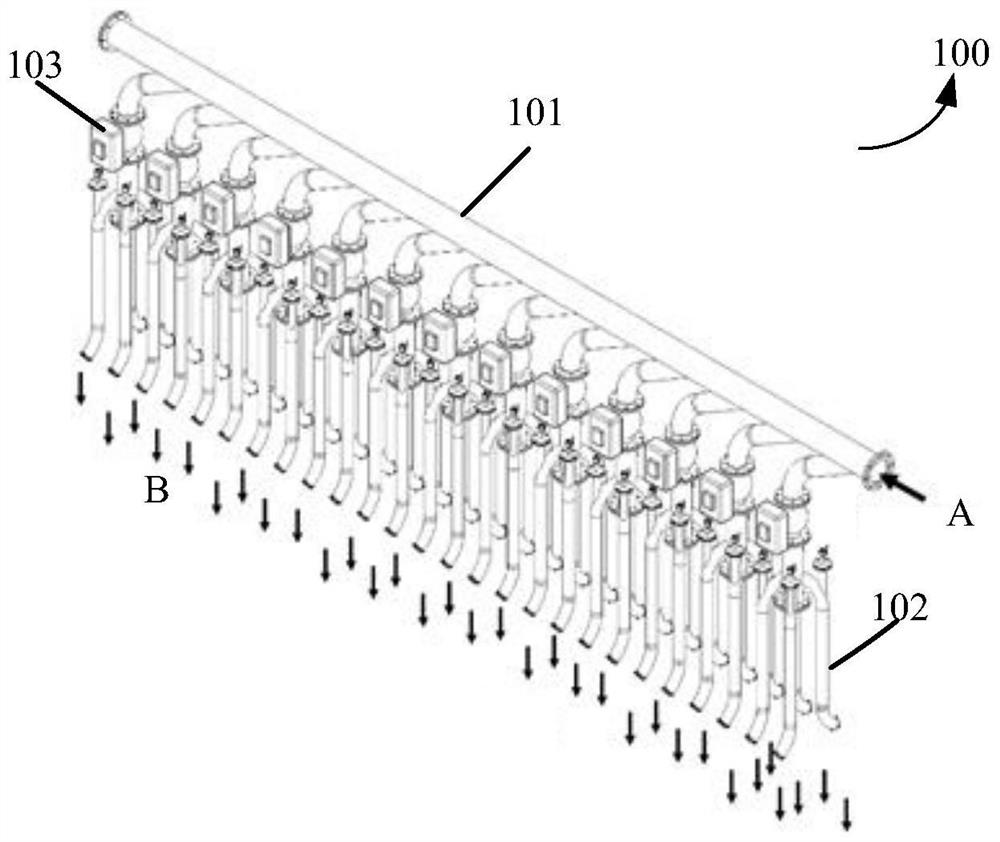

[0034] In order to solve the problems in the above-mentioned technologies, the invention provides an in-pipe sludge cleaning device for sludge distribution on an incinerator, comprising:

[0035] a feed pipe extending along a first direction for inputting sludge;

[0036] A mud removal device, the mud removal device includes a mud removal screw arranged in the feed pipe and extending along the first direction, and a driving device that drives the mud removal screw to rotate around an axis, the mud removal screw.

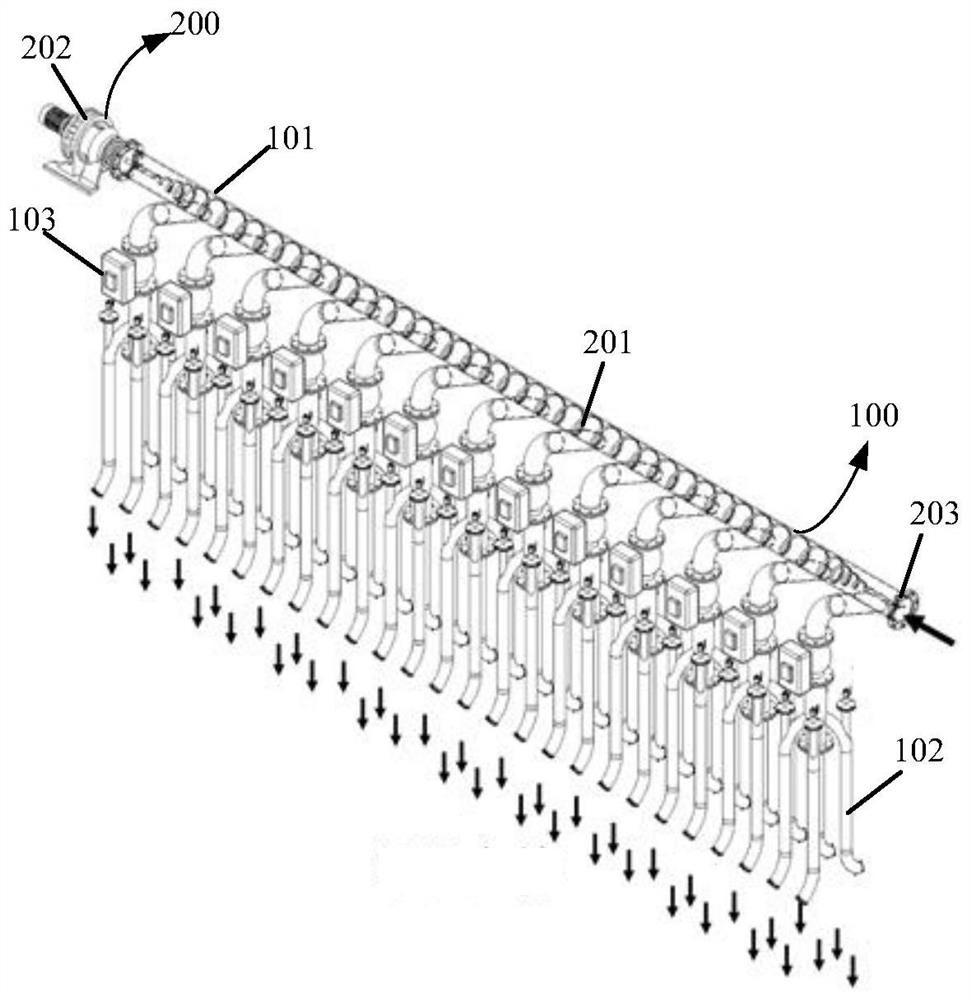

[0037] see image 3 , which shows a schematic structural view of an in-pipe sludge cleaning device for sludge distribution according to an embodiment of the present invention, which is shown in figure 2 Add a mud cleaning device 200 to the in-pipe mud cleaning device 100 for the sludge distribution.

[0038] It should be understood that this embodiment is figure 2 The sludge cleaning device 200 in the pipe of the sludge distribution device 100 is only exemplary,...

Embodiment 2

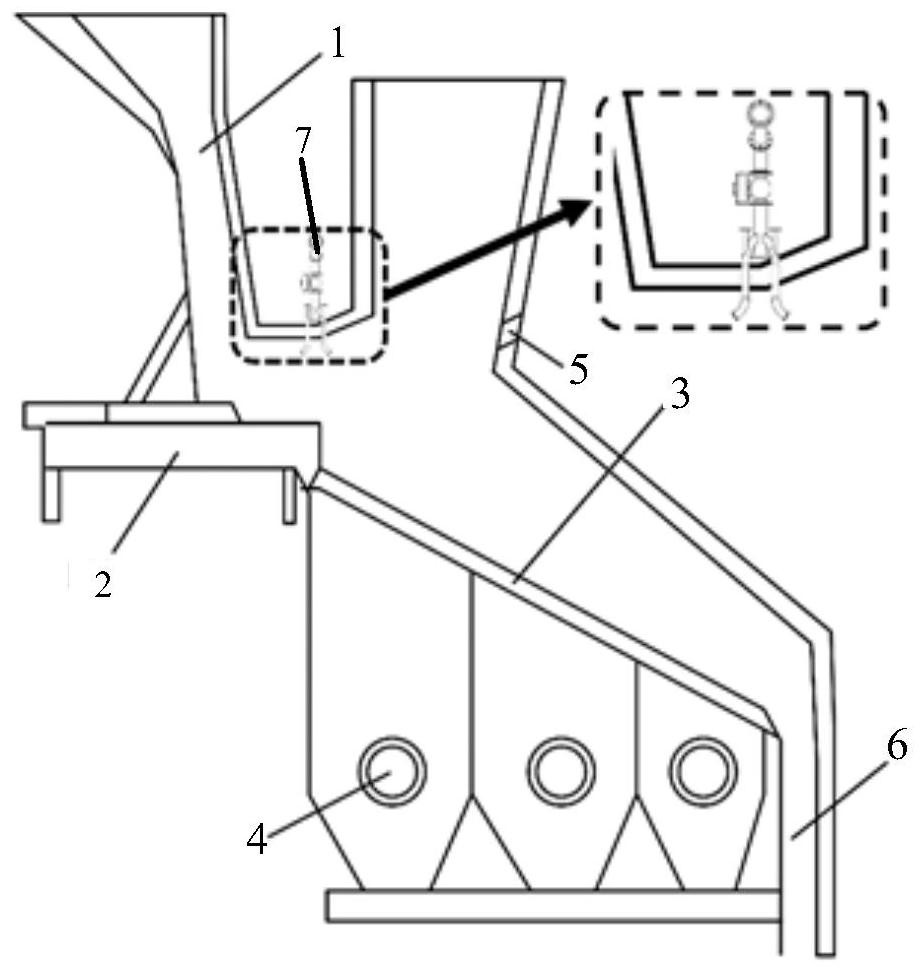

[0059] The present invention also provides a garbage incinerator, including the in-pipe sludge cleaning device for distributing sludge on the incinerator as described in the first embodiment.

[0060] Because in the incinerator according to the sludge cleaning device in the pipe of the sludge distribution device of the present invention, the sludge cleaning device for cleaning the sludge in the feed pipeline is set, when the mud cleaning screw wherein rotates around the axis, it promotes the cleaning of the sludge on the one hand. The mud advances in the input direction in the feeding pipeline to avoid sludge clogging. On the one hand, the spiral shape can loosen the sludge in the feeding pipeline, prevent the sludge from clogging in the feeding pipeline, and play the role of cleaning the sludge. ; In the garbage incinerator according to the present invention, the blockage of the sludge cleaning device in the pipe of the sludge distribution is avoided, and in the incineration p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com