Drill pipe loading arm for pumping reverse circulation drilling machine

A pump suction reverse circulation, loading and unloading arm technology, applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of heavy physical exertion of the operator, prone to accidents, unfavorable safety production, etc., to achieve convenient, fast and free installation The effect of large scale and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

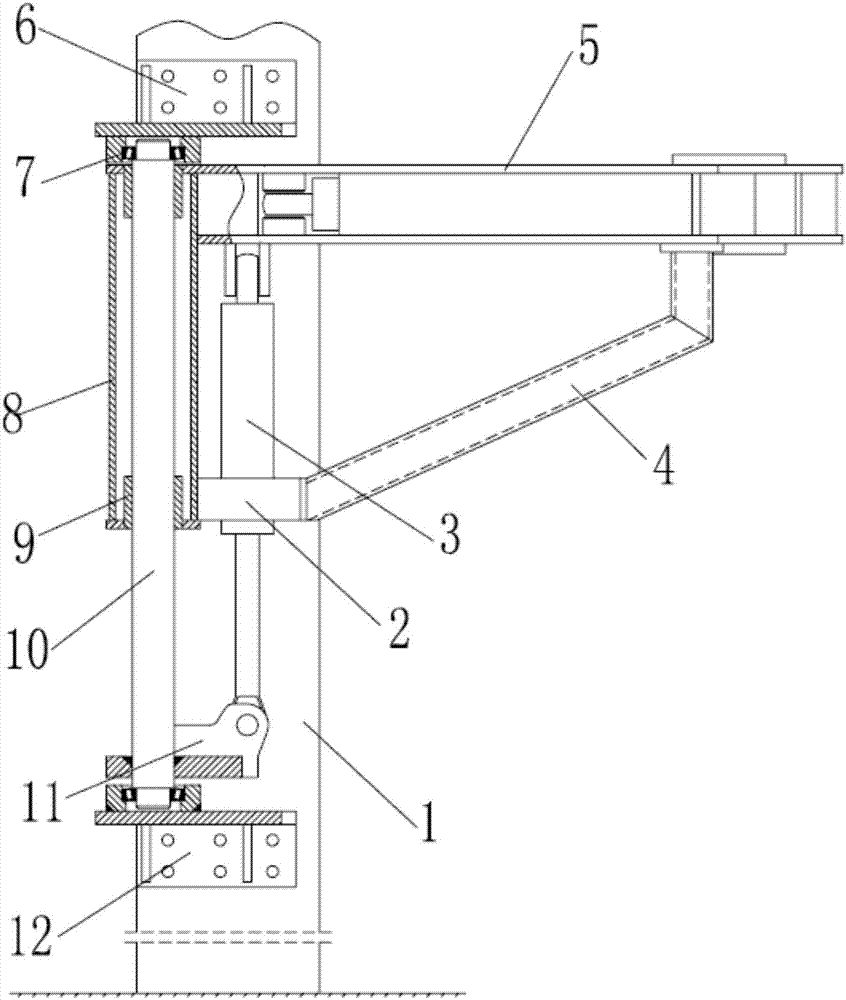

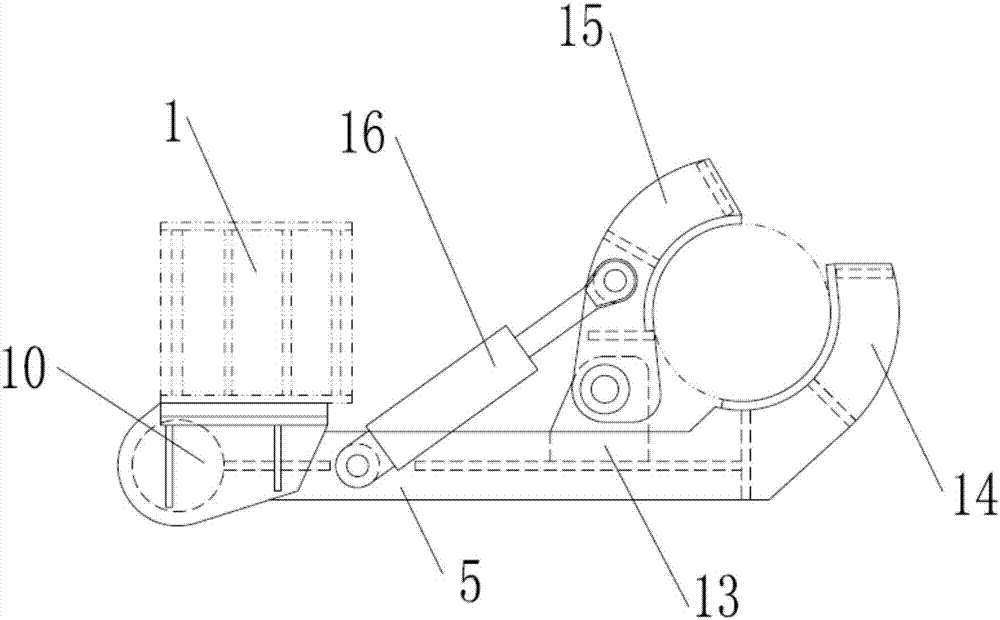

[0020] The movable clamp arm 15 and the fixed clamp arm 14 are pushed by the clamp arm cylinder 16 to clamp the drill pipe, the fixed clamp arm support 5 can rotate around the rotating shaft 10, and the movable clamp arm 15 and the fixed clamp arm 14 rotate with the fixed clamp arm support 5 To complete the centering or removal of the drill pipe; the lifting cylinder 3 drives the fixed clamp arm bracket 5 to move up and down, the fixed clamp arm bracket 5 slides up and down along the bearing 7 through the guide sleeve 8, and the movable clamp arm 15 and the fixed clamp arm 14 clamp the drill rod As the clamp arm support 5 moves up and down, the up and down movement of the drill rod is realized for the connection and disassembly of the drill rod. The upper and lower openings of the guide sleeve 8 are equipped with wear-resistant sleeves 9, and the wear-resistant sleeves 9 are sleeved on the rotating shaft 10. When the wear-resistant sleeve 9 is severely worn, only the wear-resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com