Hanging basket for installing and overhauling side face assembly of converter valve and operation method

A technology for component installation and converter valves, which is applied to scaffolding accessories, buildings, and housing structure supports, can solve the problems of low installation efficiency, poor mobility, and low efficiency, and achieve the effects of convenient disassembly, flexible transfer, and reliable load bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

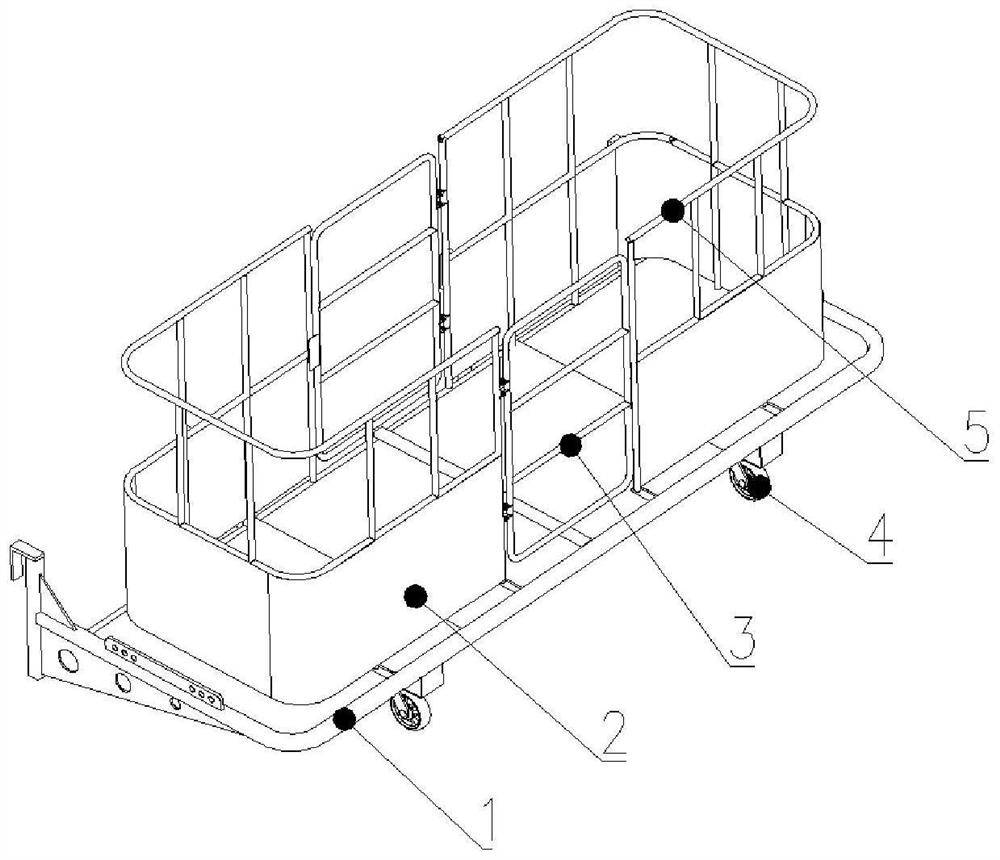

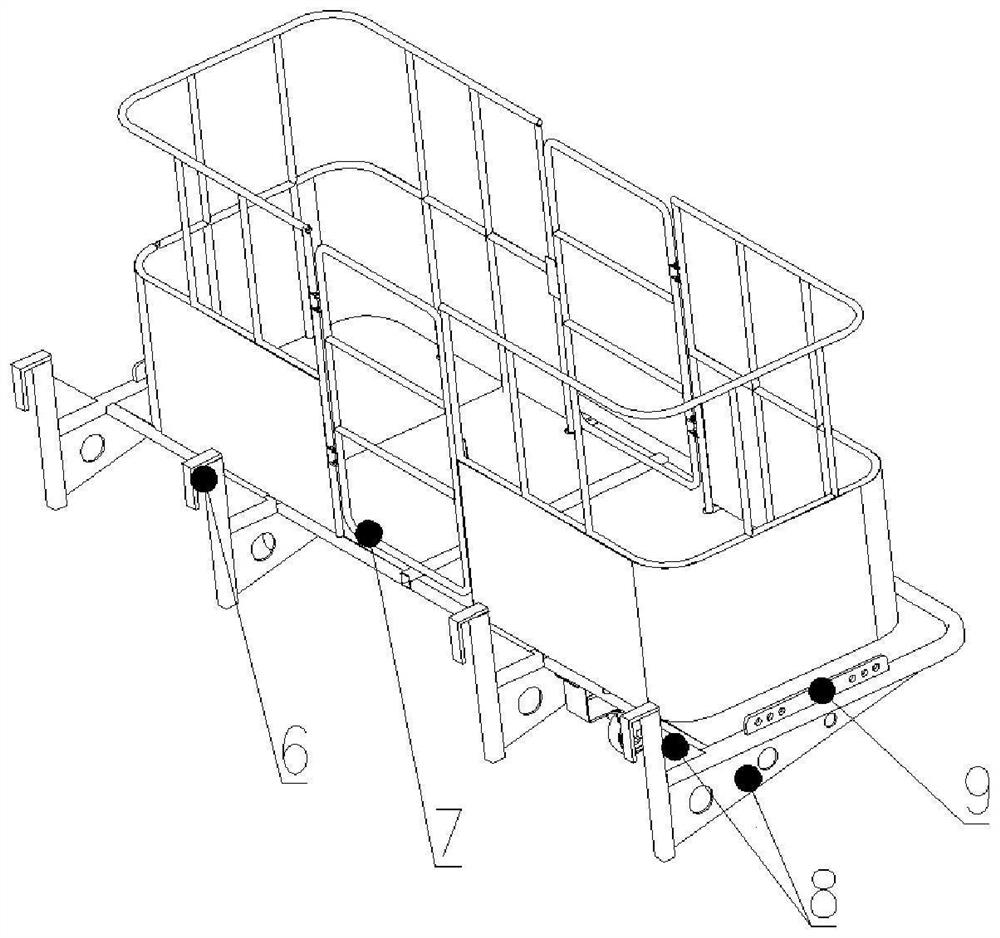

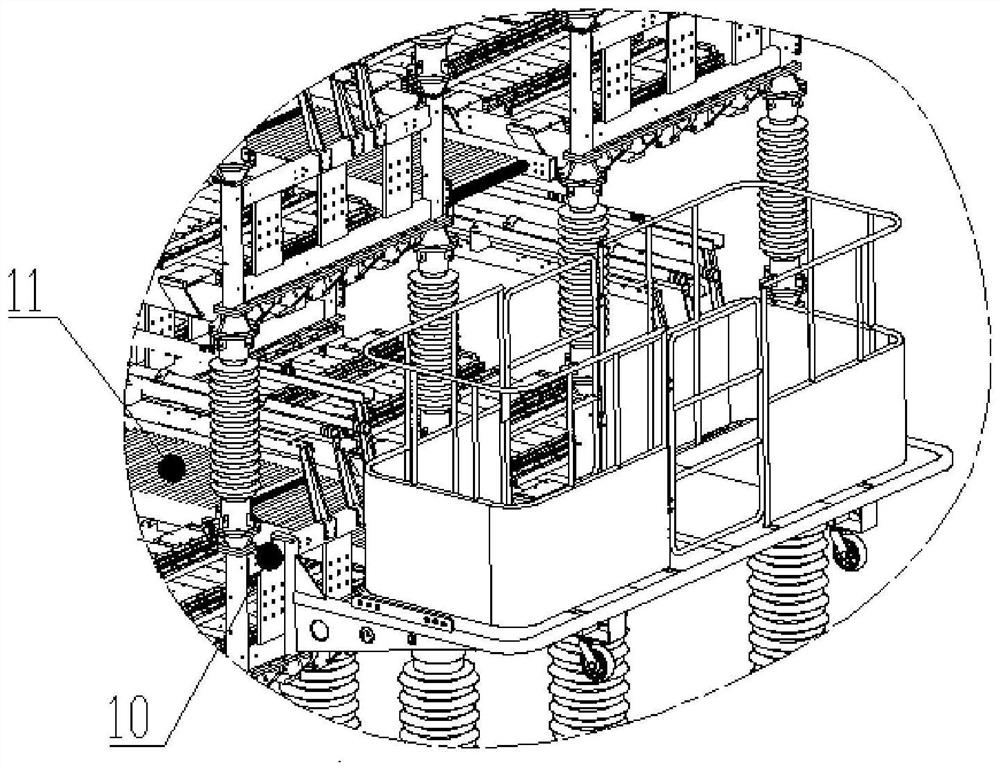

[0033] Such as Figure 1 ~ Figure 2 As shown, a hanging basket for the installation and maintenance of the side components of the converter valve includes a bottom platform 1, a protective fence, a gate rail, casters 4 and a hook 6. There is a working area on the bottom platform, and the protective fence is located on the side of the working area. Surrounding the work area, there is an entrance and exit on the protection fence, the gate is located at the entrance and exit, the gate and the protection fence are hinged, the casters are located below the bottom platform, the casters are connected to the bottom platform by rotation, the hook is fixedly connected to the bottom platform, and the protection fence includes fixing Connected fence frame 5 and iron sheet 2, the fence frame is welded by steel pipes, and the iron sheet is positioned at the bottom of the fence frame.

[0034] The number of entrances and exits is two, and the two entrances and exits are arranged oppositely a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com