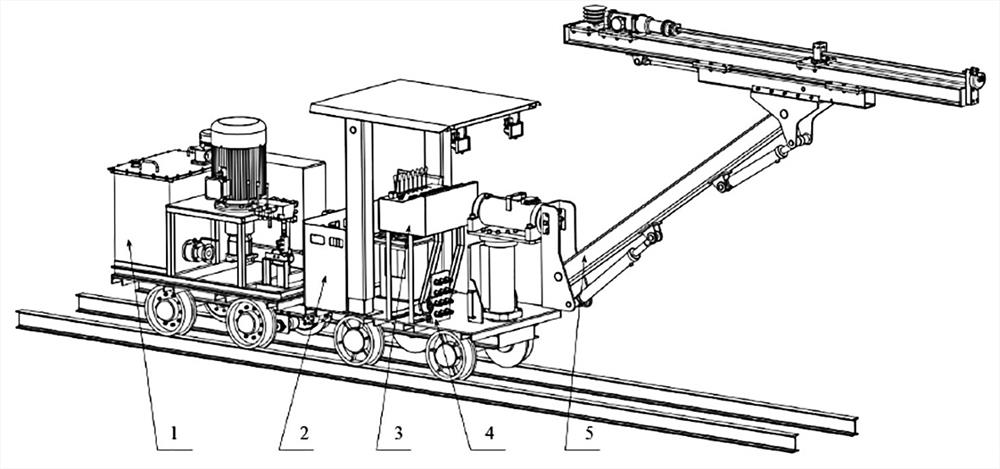

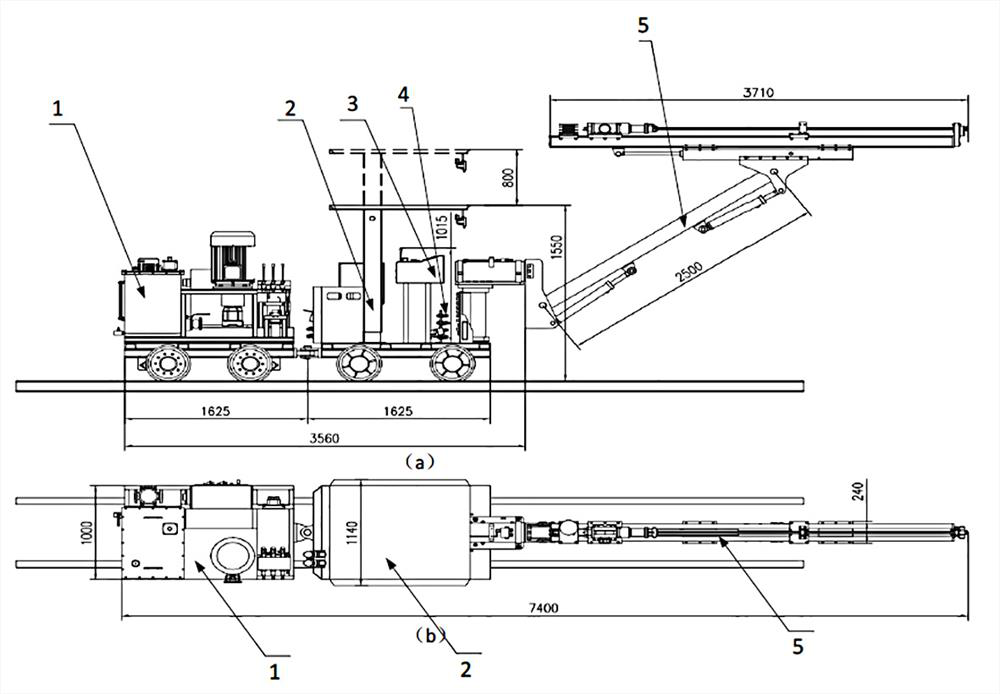

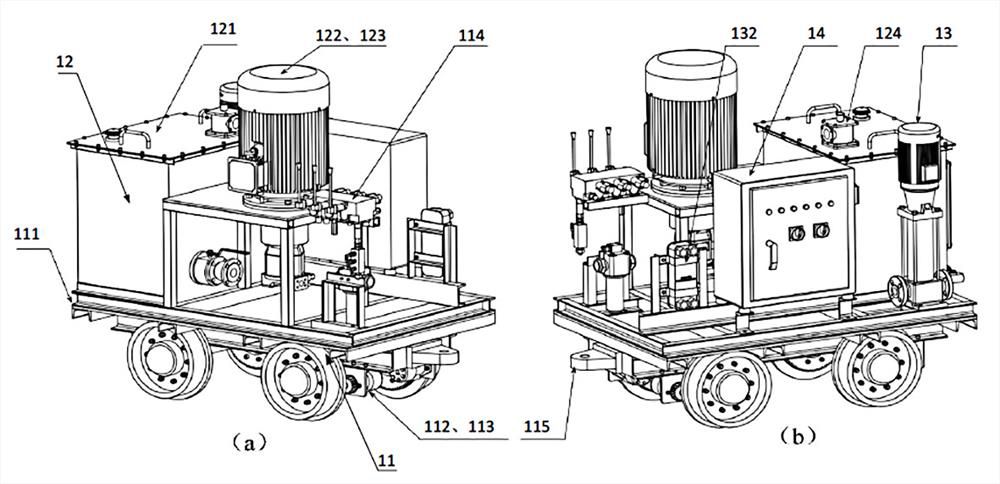

Small-section drift tunneling drill jumbo

A technology of rock drilling rig and small section, applied in the fields of construction machinery and mining machinery, can solve the problems of high labor intensity, harsh working environment, hidden safety hazards, etc., and achieve the effect of flexible transfer and efficient operation requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The small-section excavation rock drilling rig provided by the present disclosure will be described in detail below with reference to the accompanying drawings and specific embodiments. At the same time, it is explained here that, in order to make the embodiments more detailed, the following embodiments are the best and preferred embodiments, and those skilled in the art can also implement other alternative ways for some known technologies; The embodiments are only described in more detail, and are not intended to specifically limit the present disclosure.

[0055] It should be noted that references in the specification to "one embodiment," "an embodiment," "exemplary embodiment," "some embodiments," etc. indicate that the described embodiment may include a particular feature, structure, or characteristic, but Not every embodiment includes the particular feature, structure, or characteristic. Furthermore, when a particular feature, structure or characteristic is descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com