Oil injector armature quick response structure

A fast-response, fuel injector technology, applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve the problems of hindering the axial movement of the armature, and the reaction speed of the armature cannot be further improved, so as to reduce the flow resistance and reduce the ineffectiveness Injection timing, effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

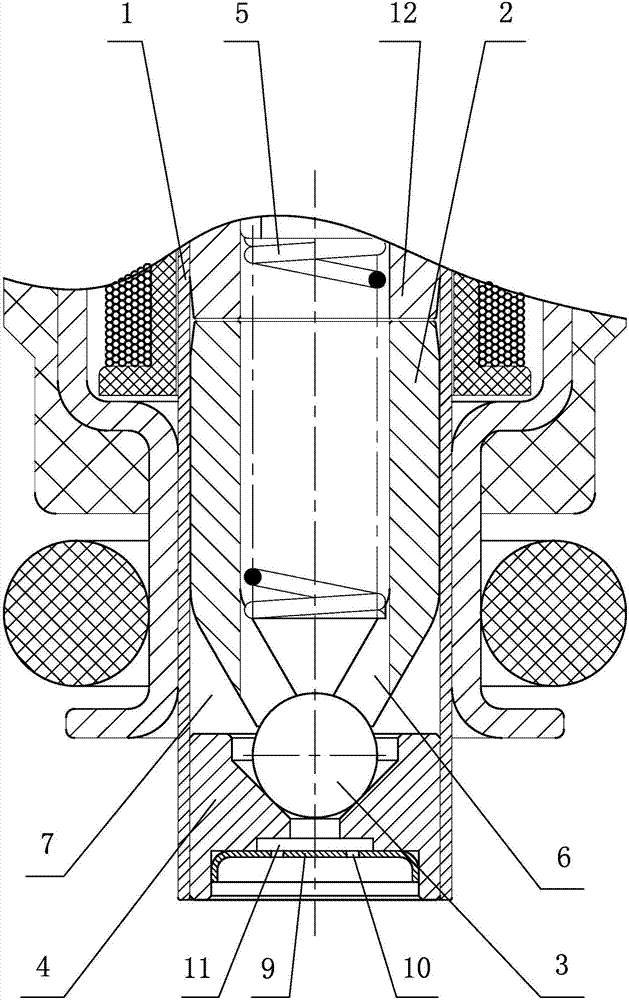

[0013] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

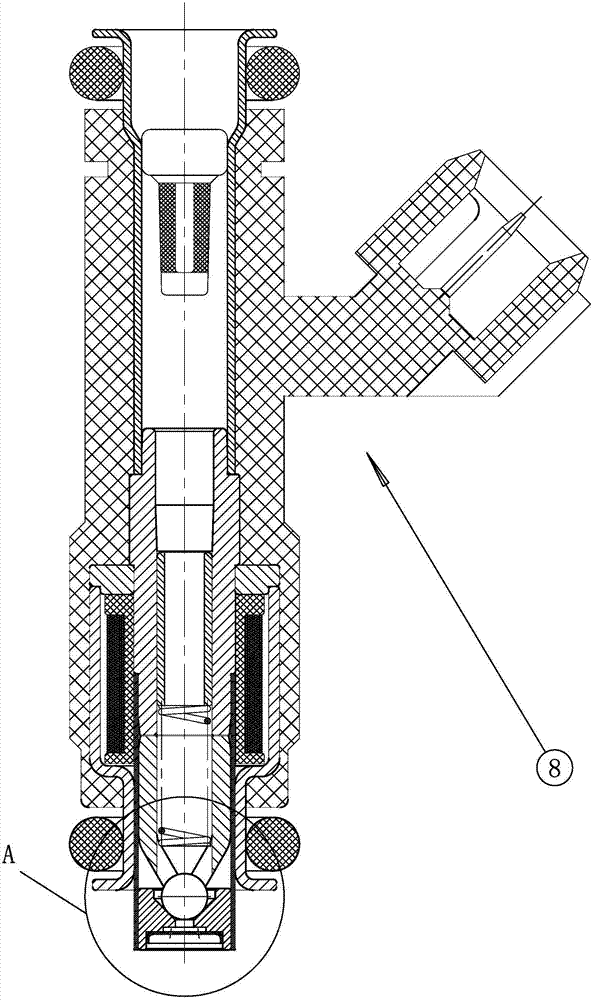

[0014] The rapid response structure of the armature of the fuel injector of the present invention, its technical solution includes a valve body structure arranged at the lower port of the magnetic isolation tube 1 at the nozzle (A) of the fuel injector 8, and the valve body structure includes a top-down coaxial Armature 2, ball valve 3, valve seat 4 and deflector 9, such as figure 1 , figure 2 shown.

[0015] The armature 2 includes an upper circular tube and a lower conical tube (the cone angle is downward). A flow-through cone cavity 7 is formed between the conical tube of the armature 2 and the magnetic isolation tube 1. The internal pressure of the circular tube of the armature 2 is equipped with a return spring. 5. The ball valve 3 is fixedly connected to the bottom of the lower conical tube of the armature 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap