Feed-back type capacity check discharge device for storage battery and application method of said device

A battery pack, nuclear capacitor discharge technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as power incidents, unenvironmental protection, and expanding the scope of accidents, to reduce maintenance costs, extend service life, and ensure safety. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

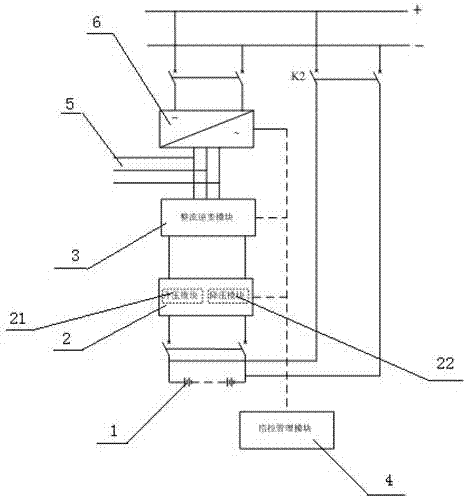

[0034] Such as figure 1 Shown is an embodiment of a regenerative battery pack core capacity discharge device and its application method. The core capacity discharge device includes a sequentially electrically connected battery pack 1, a DC chopper module 2, and a rectification and inverter module 3. The core capacity discharge device includes A monitoring and management module 4 for monitoring the current and voltage of the device. The monitoring and management module 4 is electrically connected to the battery pack 1, the DC chopper module 2, and the rectification and inverter module 3. The nuclear capacity discharge device is provided with a three-phase power supply for charging 5. The three-phase power supply 5 is electrically connected to the rectifier and inverter module 3; the nuclear capacity discharge device includes a load, and the load is electrically connected to the battery pack 1 and the rectifier and inverter module 3.

[0035] Wherein, the nuclear capacity discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com