Neutral gear and reverse gear switch structure in gearbox

A switch structure and gearbox technology, applied in electrical switches, components with teeth, electrical components, etc., can solve problems such as poor sealing effect, and achieve the effects of sealing performance oil, good structural versatility, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

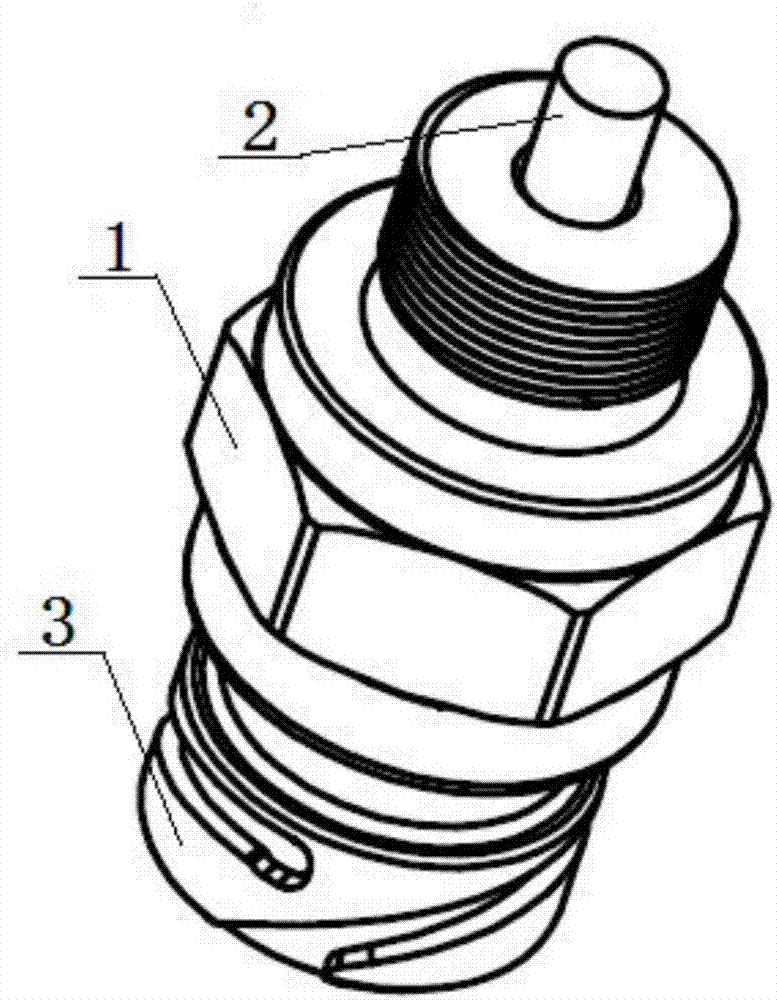

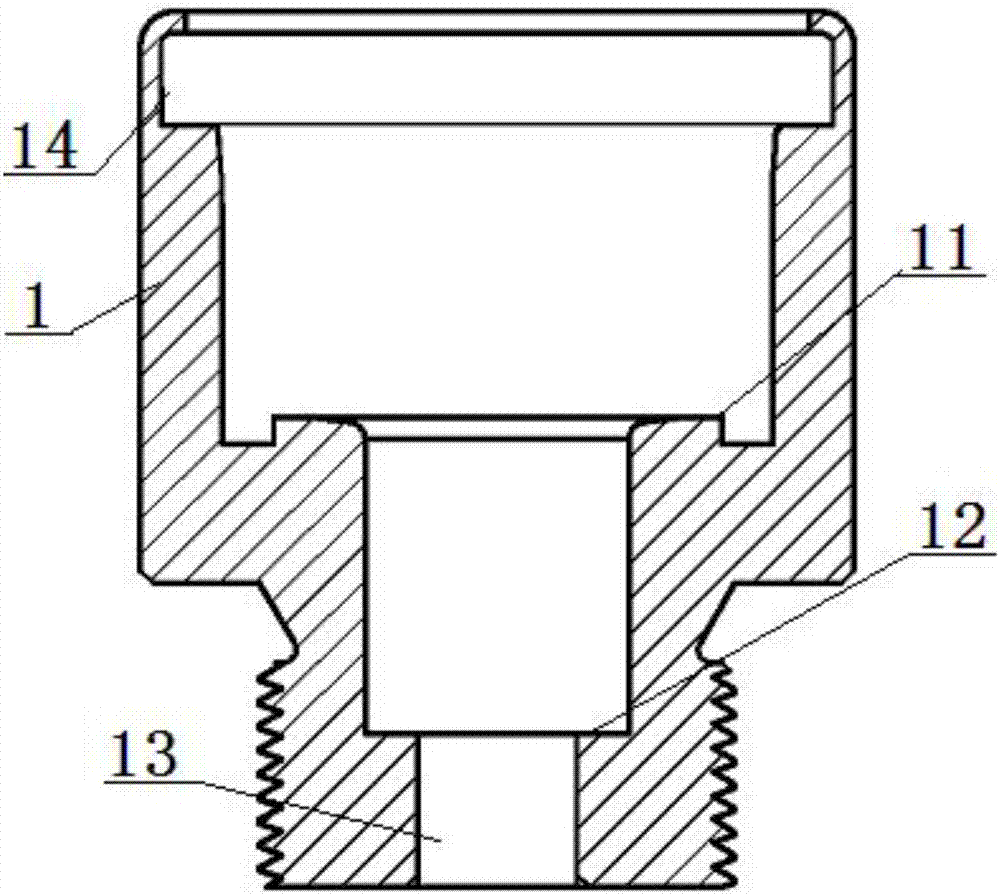

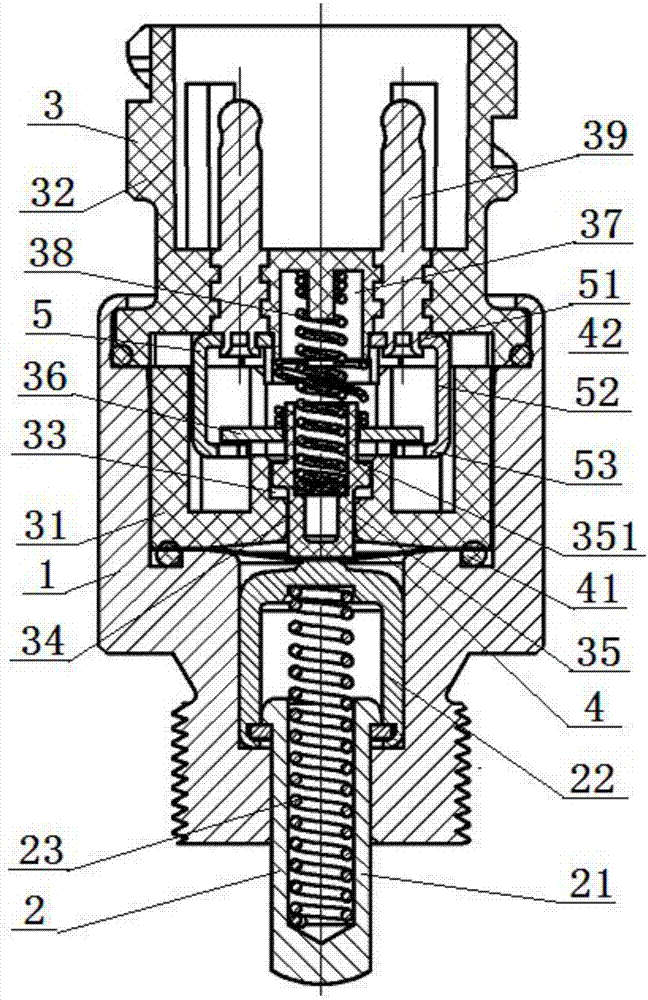

[0046] see Figure 1 to Figure 4 , an idle and reverse gear switch structure in a gearbox, comprising: a housing 1 and a feeler rod 2, the feeler rod 2 is arranged in the housing 1; the switch also includes a switch core 3, and the housing 1 There is a core mounting platform 11 inside, a stem mounting platform 12 is provided in the middle of the bottom surface of the core mounting platform 11, and a contact rod sliding hole 13 is provided in the middle of the bottom surface of the contact rod mounting platform 12, One end of the contact rod 2 is limitedly matched with the contact rod installation platform 12, and the other end of the contact rod 2 is slidably matched with the contact rod sliding hole 13; the lower end of the switch core 3 is fitted with the core component installation platform 11 The top of the switch core part 3 is tightly fitted, and the bottom surface of the switch core part 3 is sealed and matched with the core part installation platform 11 through the oil...

Embodiment 2

[0048] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0049] see image 3 , the section of the static contact piece 5 is C-shaped, the static contact piece 5 includes an upper fixed piece 51, a middle contact piece 52 and a lower contact piece 53, the middle part of the upper fixed piece 51 is connected with the metal plug 39, The side of the upper fixed piece 51 is vertically connected to the upper end of the middle contact piece 52, the lower end of the middle contact piece 52 is vertically connected to the lower contact piece 53, and the metal movable contact piece 36 is arranged between the upper fixed piece 51 and the lower Between the contact pieces 53, the metal movable contact piece 36 is in contact with the lower contact pieces 53 on both sides respectively; the top of the contact button 35 is provided with a spring fixing hole 351, and one end of the contact piece spring 38 is arranged on the spring In the fixing hole 351 , the other en...

Embodiment 3

[0051] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0052] see Figure 4 , the section of the static contact piece 5 is L-shaped, the static contact piece 5 includes an upper fixed piece 51 and a contact piece 54, the middle part of the upper fixed piece 51 is connected with the metal plug 39, and the upper fixed piece 51 The side portion of the contact piece 54 is vertically connected to the upper end of the contact piece 54, and the distance from the metal moving contact piece 36 to the bottom of the contact piece 54 is less than the maximum stroke of the touch button 35; the top of the touch button 35 is provided with a spring fixing rod 352, the One end of the contact spring 38 is set in the spring installation groove 37, and the other end of the contact spring 38 is sleeved on the spring fixing rod 352, and the bottom of the contact spring 38 is tightly fitted with the top surface of the metal movable contact 36. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com