Mask and preparation method thereof, color film substrate and preparation method thereof as well as naked-eye 3D (three dimensional) display device and application

A technology for a color filter substrate and a display device is applied in the field of naked-eye 3D display devices, and can solve the problems of increasing the thickness of the display device, increasing the cost, and inconvenience to the viewer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

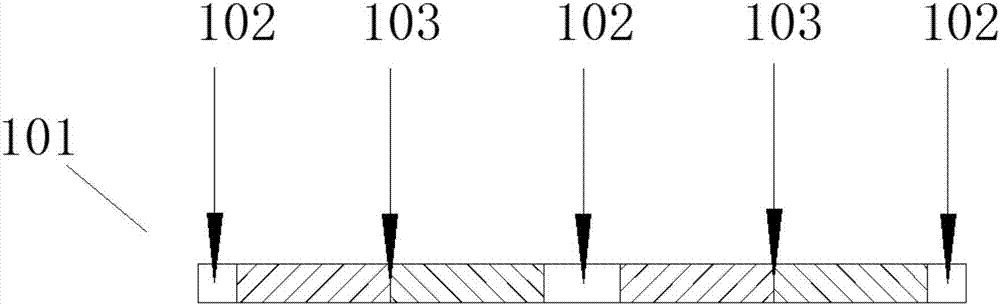

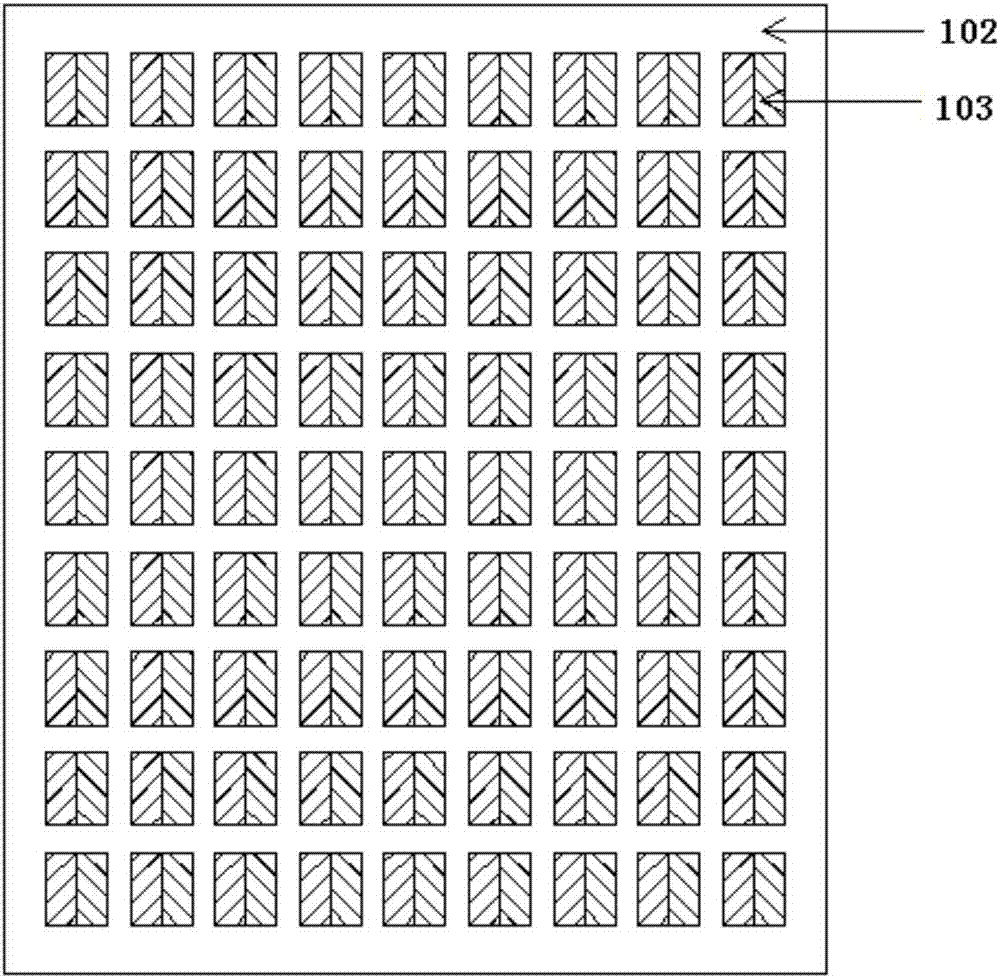

[0040] The present invention also provides the preparation method of above-mentioned mask plate, and this method comprises the following steps:

[0041] (1) preparing the light-transmitting film to have non-uniform light transmittance;

[0042] (2) Place the light-transmitting film obtained in step (1) on the light-transmitting region 103 of the mask plate 101 .

[0043] According to the method of the present invention, in step (1), the purpose of the preparation method is to prepare a light-transmitting film with inhomogeneous light transmittance, and the preparation method is not particularly limited. For example, the preparation method can be physical drawing Stretching.

[0044] According to the method of the present invention, the physical stretching method can be that the light-transmitting film is placed in the two clamps of the biaxial stretching machine, so that the longitudinal axis of the light-transmitting film coincides with the center line of the upper and lower...

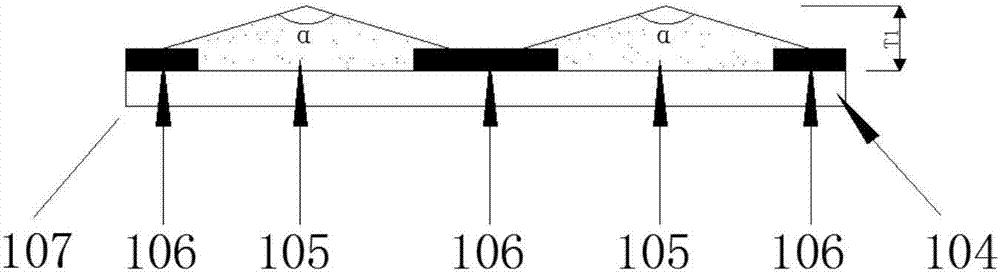

Embodiment 1

[0063] (1) Preparation of light-transmitting film with uneven light transmittance

[0064] Place the light-transmitting film made of chromium oxide film (purchased from Dainippon Printing Co., Ltd.) in the two clamps of the biaxial stretching machine (purchased from Hengyi Precision), so that the longitudinal axis of the light-transmitting film is aligned with the center of the upper and lower clamps. The connecting lines overlap, set the stretching limit to 170% of the length of the light-transmitting film, stretch the light-transmitting film at a speed of 2mm / min, and stop stretching when the light-transmitting film reaches the stretching limit.

[0065] The transmittance of the light-transmitting film was measured by a spectrometer (purchased from Otsuka Electronics Co., Ltd.), and the measurement result was: a smooth transition from 70% at the geometric center to 0% at the edge.

[0066] (2) Preparation of mask plate

[0067] Such as figure 1 with figure 2 As shown, th...

Embodiment 2

[0074] (1) Preparation of light-transmitting film with uneven light transmittance

[0075] According to the method of embodiment 1, the difference is that the material of the light-transmitting film is a molybdenum-silicon oxide film (purchased from Dainippon Printing Co., Ltd.), and the tensile limit is set to be 180% of the length of the light-transmitting film, with a rate of 2.2mm / min Stretch the light-transmitting film at a certain speed, and stop stretching when the light-transmitting film reaches the stretching limit.

[0076] The light transmittance was measured according to the method of Example 1, and the measurement result was: a smooth transition from 70% at the geometric center to 0% at the edge.

[0077] (2) Preparation of mask plate

[0078] According to the method of embodiment 1.

[0079] (3) Preparation of color filter substrate

[0080] According to the method of Embodiment 1, the difference is that a color photoresist with a thickness of 3.3 μm is coated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com