A full-surface foldable touch screen and its manufacturing method and application

A production method and touch screen technology, applied in the direction of instrumentation, calculation, electrical digital data processing, etc., can solve the problems of signal short circuit, short service life, easy cracking and damage of ITO, etc., so as to improve service life and stability, and solve problems The effect of resistance to bending and improving the effect of folding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

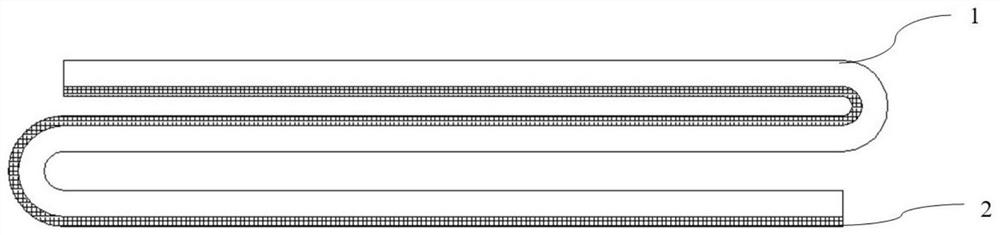

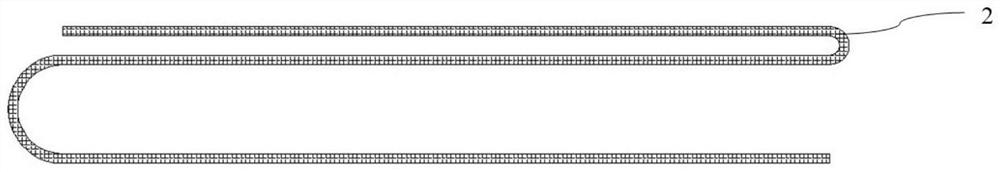

[0054] According to the shape of the foldable display device (such as figure 1 ) Design the corresponding touch screen shape (such as figure 2 ) and mark the folded area.

[0055] The process flow of ITO+graphene composite touch screen (i.e. the whole surface of the present invention can be bent touch screen) is as follows (such as Figure 5 ):

[0056] 1) Mark the area to be folded on the 25 micron thick ITO conductive film;

[0057] 2) transferring the single-layer graphene film at the marked folded region;

[0058] 3) The entire graphene + ITO conductive film is patterned by the laser direct writing process, so that the graphene as the metal lead area of the touch sensor is removed, exposing the surface of the ITO conductive film, so that the metal lead can be overlapped with ITO;

[0059] 4) Print silver paste wires, so that the silver paste and the ITO conductive film overlap to form a complete touch circuit;

[0060] 5) Use laser direct writing patterning to patt...

Embodiment 2

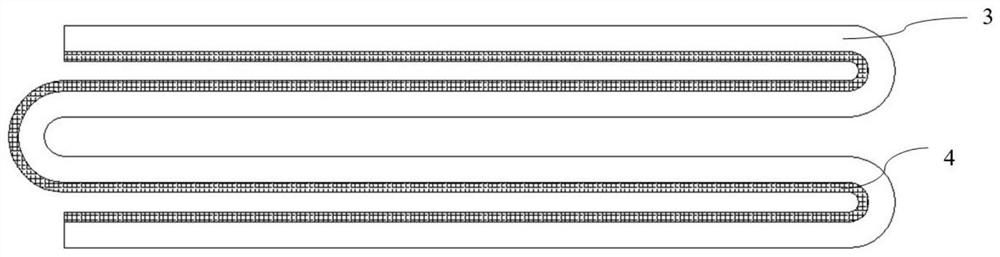

[0063] According to the shape of the foldable display device (such as image 3 ) Design the corresponding touch screen shape (such as Figure 4 ) and mark the folded area.

[0064] The process flow of ITO+graphene composite touch screen is as follows (such as Image 6 ):

[0065] 1) Mark the area to be folded on the 50 micron thick ITO conductive film;

[0066] 2) transfer the bilayer graphene film at the marked folded region;

[0067] 3) The entire graphene + ITO conductive film is patterned by the laser direct writing process, so that the graphene as the metal lead area of the touch sensor is removed, exposing the surface of the ITO conductive film, so that the metal lead can be overlapped with ITO;

[0068] 4) Print silver paste wires, so that the silver paste and the ITO conductive film overlap to form a complete touch circuit;

[0069] 5) Use laser direct writing patterning to pattern silver paste and other ITO and graphene coverage areas to form touch sensor patte...

Embodiment 3

[0072] According to the shape of the foldable display device (such as figure 1 ) Design the corresponding touch screen shape (such as figure 2 ) and mark the folded area.

[0073] The process flow of ITO+graphene composite touch screen is as follows (such as Figure 5 ):

[0074] 1) Mark the area to be folded on the 25 micron thick ITO conductive film (corresponding to the bending part of the ITO conductive layer, the same below);

[0075] 2) transferring the single-layer graphene film at the marked folded region;

[0076] 3) The entire graphene + ITO conductive film is patterned by the laser direct writing process, so that the graphene as the metal lead area of the touch sensor is removed, exposing the surface of the ITO conductive film, so that the metal lead can be overlapped with ITO;

[0077] 4) Copper wire is sputtered, so that the copper wire overlaps with the ITO conductive film to form a complete touch circuit;

[0078] 5) Use laser direct writing patterning t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com