Water bath dedustor

A dust collector and water bath technology, applied in fixed filter element filters, gravity filters, chemical instruments and methods, etc., can solve the problems of mixing, reducing the working efficiency of dust collectors, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

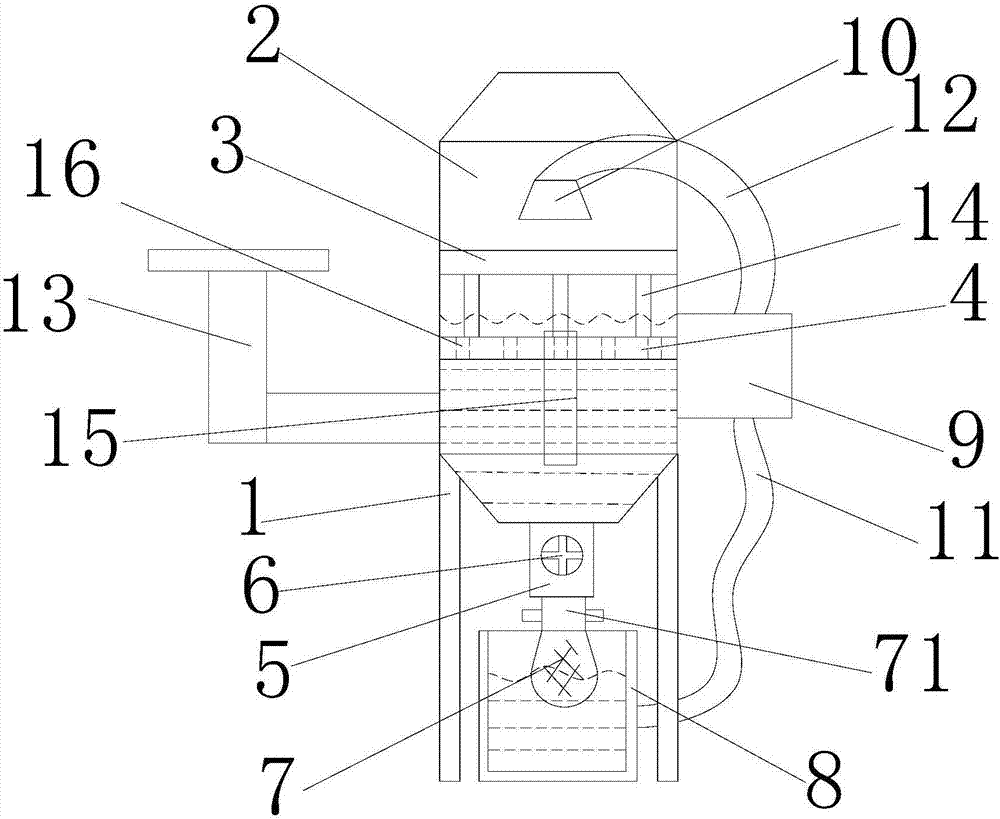

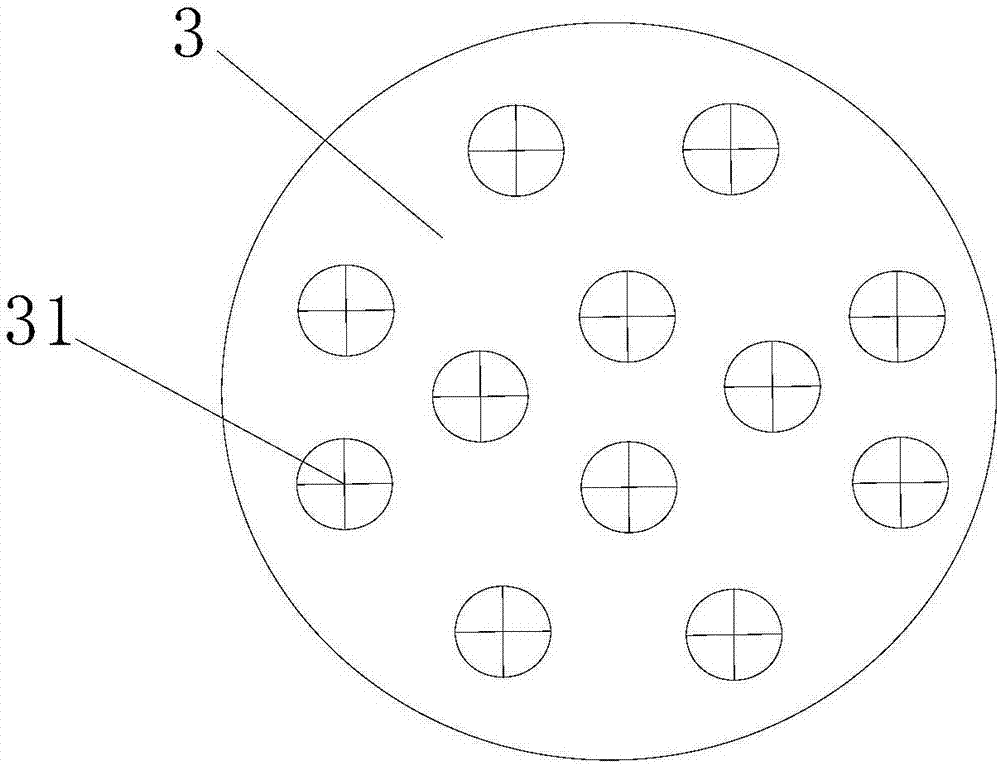

[0014] refer to figure 1 and 2 , a water-bath dust collector of the present invention, comprising a bracket 1, a water storage cylinder 2, a filter screen 3, a floating plate 4, an outlet pipe 5, a valve 6, a filter bag 7, a water tank 8, a water pump 9, a nozzle 10, a suction pipe 11, Water injection pipe 12, air intake pipe 13, support rod 14, observation window 15 and through hole 16, the top of described support 1 is fixedly provided with water storage cylinder 2, and the inner side of described water storage cylinder 2 slides and is provided with the filter screen 3 that horizontally arranges, The bottom of the filter screen 3 is provided with a floating plate 4 slidingly matched with the inner wall of the water storage cylinder 2, the lower part of the water storage cylinder 2 is connected with a water outlet pipe 5, and the side of the water outlet pipe 5 is provided with a valve 6. The outlet end of the water outlet pipe 5 is detachably connected with a first filter b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap