Wind-power dry magnetic separation machine for fine ore

A magnetic separator and wind power technology, applied in the direction of magnetic separation, solid separation, and separation of solids from solids with airflow, can solve the problems of inability to use selection operations, difficult to sort fine-grained materials, etc., and achieve Effect of reducing inclusions, improving concentrate grade, and efficient beneficiation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail without limitation in conjunction with the accompanying drawings and examples below.

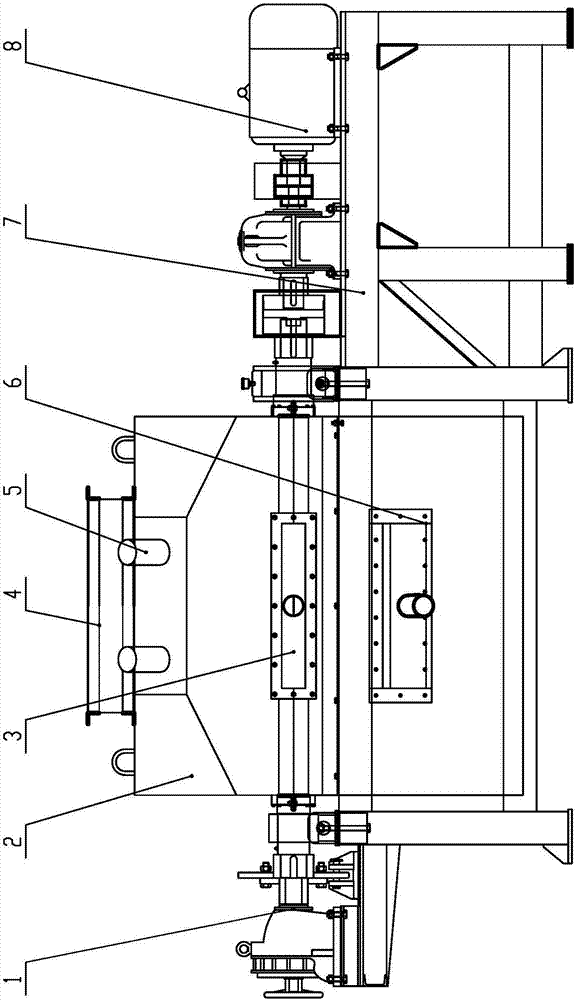

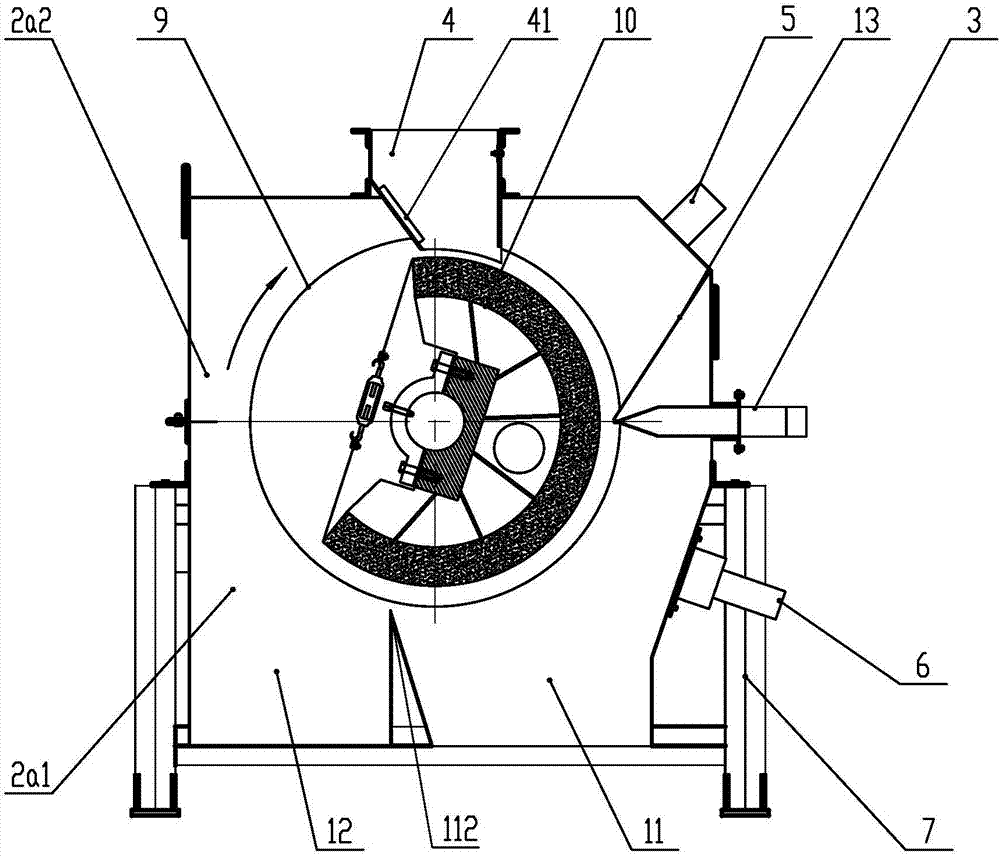

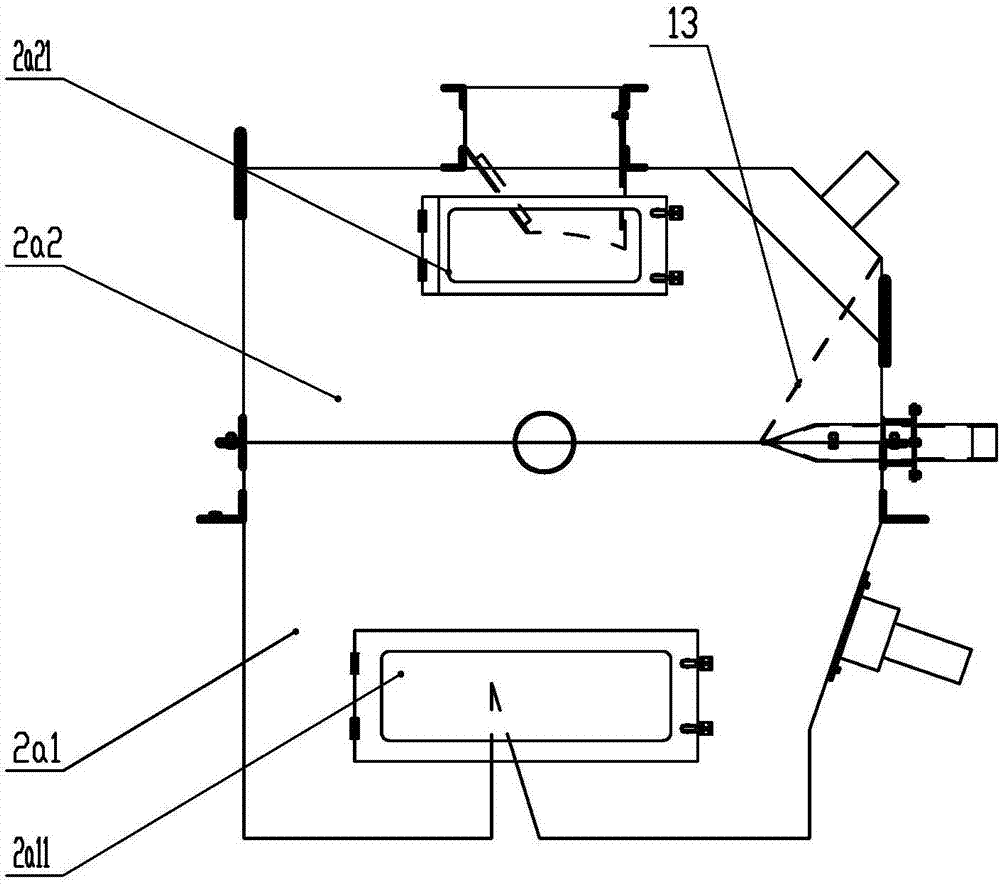

[0029] Such as figure 1 and figure 2 As shown, the fine ore wind-driven dry magnetic separator of the present invention includes: a sorting box 2 arranged on the frame 7, a permanent magnet drum 9 is arranged in the sorting box 2, and the permanent magnet drum 9 includes a cylinder arranged in rotation. body and a fixed magnetic system 10, the magnetic system 10 is set in the cylinder, the cylinder is driven by the power device 8, and the frame 7 is also provided with a magnetic system adjustment device 1; the upper part of the sorting box 2 is provided with a feeding port 4 A uniform ore separation device 41 is arranged in the ore feeding port 4, a concentrate port 12 and a tailings port 11 are provided at the bottom of the sorting box 2, and a material distribution device 112 is arranged between the concentrate port 12 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com