Stamping and material-taking high-stability mechanical arm

A stable, manipulator technology, applied in the direction of launching equipment, etc., can solve problems affecting the accuracy and service life of manipulators, poor stability, and reduce workers, so as to improve the bearable load and stability, ensure rigidity and accuracy, and improve dynamic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

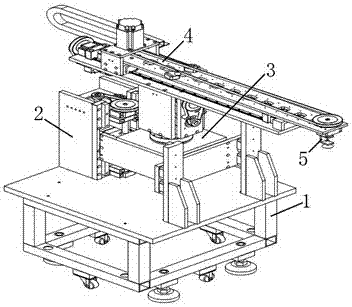

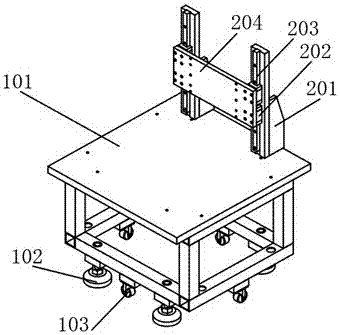

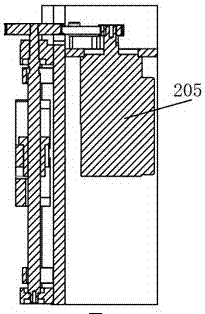

[0026] like Figure 1 to Figure 10As shown, the high-stability manipulator for stamping and reclaiming in this embodiment includes a base part 1, a vertical movement module 2, a swing arm rotation module 3, a horizontal movement module 4, and an execution end rotation module 5. The vertical movement module 2 is fixed On the bottom plate 101, it drives the rest of the motion modules to move up and down. The swing arm rotation module 3 is installed on the active mounting plate 214 and the driven mounting plate 204, and drives the horizontal movement module 4 to rotate the rotating module 5 at the execution end. The horizontal movement module 4 is connected to the harmonic reducer 302, and drives the execution end rotation module 5 to translate. The execution end rotation module 5 is installed on the second active slider 422, and drives the execution end rotation shaft 506 and the suction cup 508 to rotate. It is characterized in that: the base part 1 is composed of a base plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com