Workpiece intelligent taking device and application thereof

An intelligent, workpiece technology, applied in tool storage devices, circuit devices, battery circuit devices, etc., can solve the problems of wasting manpower, wasting time, reducing work efficiency, etc., avoiding moving or dumping, ensuring clean quality, and saving production time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment provides an intelligent workpiece access device, including:

[0054] - The walking device is used to drive the intelligent access device to move according to the set program;

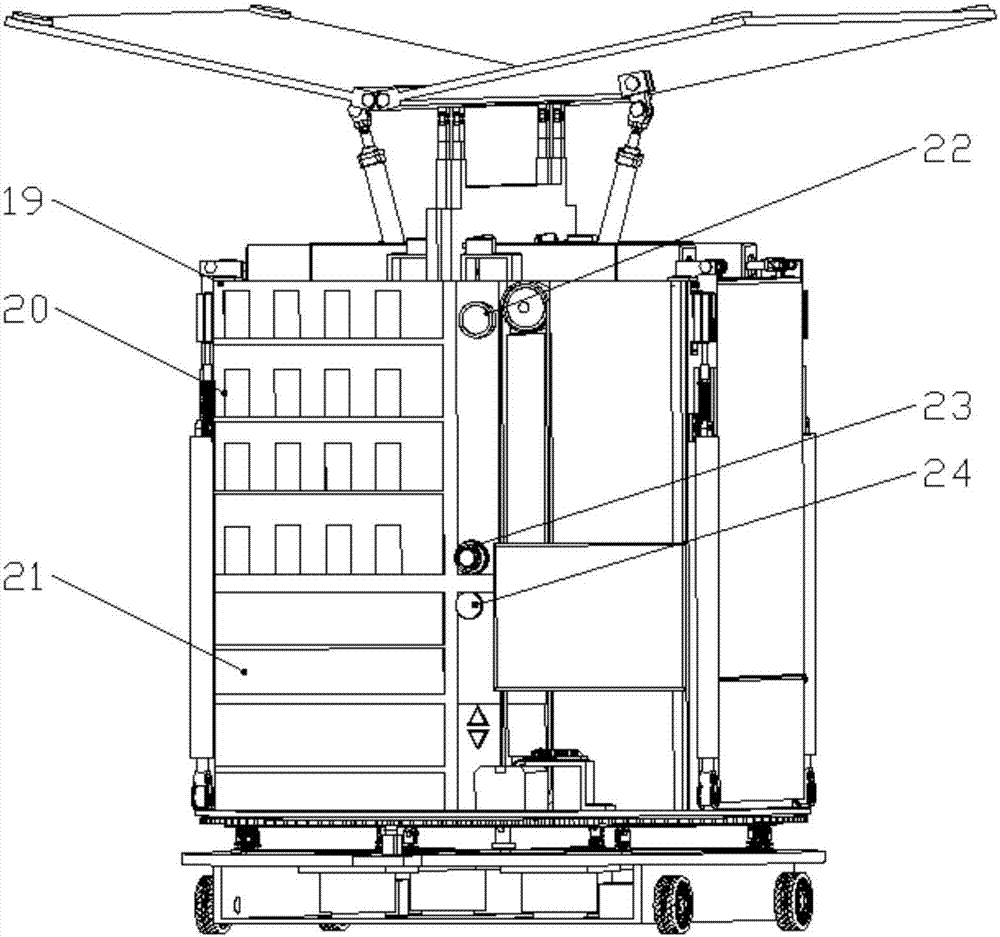

[0055] —The box body is set on the walking device, including the workpiece storage cabinet and the movable panel. The movable panel is located on the side of the workpiece storage cabinet and can move up and down;

[0056] —PLC controller, used to control the operation of the traveling device and the movable panel;

[0057] —A storage battery and a solar automatic collection device, the solar automatic collection device converts solar energy into electrical energy and stores it in the storage battery, and the storage battery provides power for the intelligent access device.

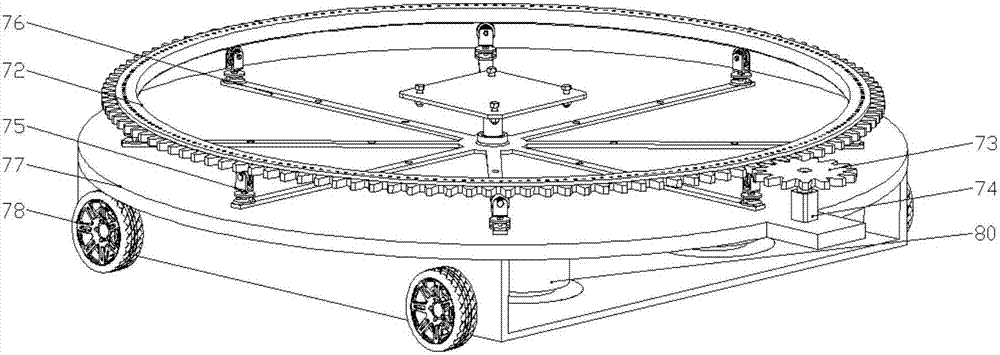

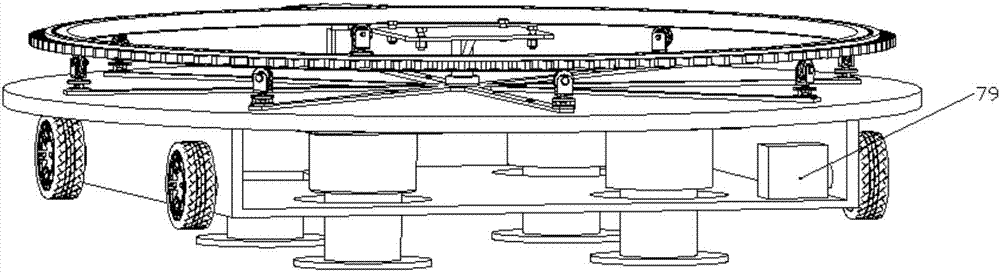

[0058] Wherein, walking device comprises base 77, wheel 78, wheel drive motor 79, star support frame 76, square bottom plate, support wheel 75, wheel disc 72, driving gear 73 and wheel disc drive motor 74; W...

Embodiment 2

[0067] An intelligent workpiece retrieval device, the structure of which is as described in Embodiment 1, the difference is that: the function of the intelligent workpiece retrieval device is enriched, which is convenient for workers to take a temporary rest or prevent falling objects from height. A movable side plate is provided, and the movable side plate includes an upper side plate 46, a lower side plate 47, a top hydraulic cylinder 17, a side plate cylinder 53, a side plate pinion 52, a side plate drive gear 51, a lower side plate drive motor 50, a side plate The plate rotating shaft 49 and lifting lug 48, the top hydraulic cylinder 17 is installed on the top of the box body 19 and placed in the hydraulic cylinder protective cover 18, the piston rod of the top hydraulic cylinder 17 is connected to the upper side through a rack and pinion transmission (not shown in the figure). Plate 46 is connected, and the top of lower side plate 47 is provided with described side plate r...

Embodiment 3

[0070] An intelligent workpiece retrieval device, the structure of which is as described in Embodiment 2, the difference lies in: in order to maintain the internal environment of the workshop, it can clean up processing waste in a timely and effective manner. The casing also includes a waste collection device, which is positioned at the back side of the workpiece storage cabinet 20. The waste collection device includes an upper push pedal 57, a lower push pedal 59, a push pedal cylinder 67, a lead screw drive motor 60, a lead screw 62, an outer Baffle plate 54 and movable baffle 55, the output shaft of lead screw drive motor 60 is connected with leading screw 62 transmission, movable baffle 55 is arranged on outer baffle 54 below and is screwed with leading screw 62 and movable baffle 55 is positioned at outer baffle 54 inner side, described upper push plate 57 and lower push plate 59 are set at outer baffle plate 54 inner sides, lower push plate 59 is hinged with upper push pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com