Anti-explosion wheel type inspection robot

An inspection robot and robot technology, applied in the field of robots, can solve the problems of low efficiency and high labor intensity, and achieve the effect of flexible movement and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

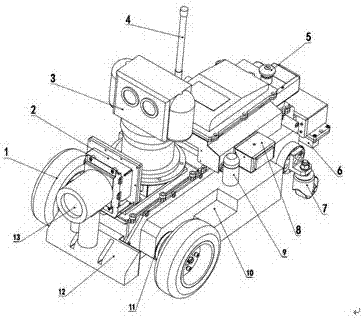

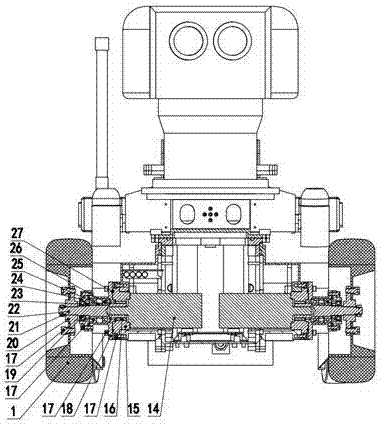

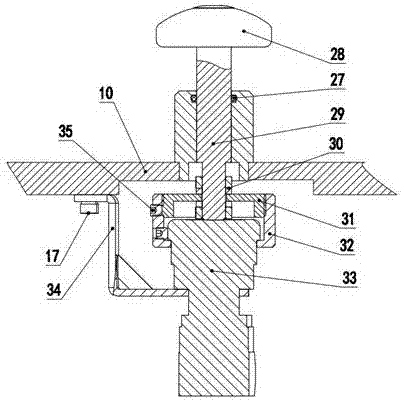

[0019] refer to figure 1 , In the first embodiment of the present invention, an explosion-proof wheeled inspection robot is provided, mainly including: driving wheel 1, RFID explosion-proof controller 2, pan-tilt camera 3, communication antenna 4, explosion-proof emergency stop button mechanism 5, explosion-proof Navigation components 6, universal wheels 7, sensors 8, warning lights 9, main cavity 10, main drive mechanism 11, RFID antenna 12, combustible gas detector 13 and other components.

[0020] Preferably, the driving wheel 1 is installed on the main drive mechanism 11 and is located at the rear of the robot; the universal wheels 7 are installed on both sides of the main cavity 10, one set each on the left and right, and are located at the front of the robot; the explosion-proof The navigation component 6 is installed at the front end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com