Full-bamboo-surface honeycomb-structure composite plate and manufacturing device and method

A technology of honeycomb structure and manufacturing device, which can be used in adhesive application devices, other plywood/plywood appliances, manufacturing tools, etc., can solve the problems of heavy weight, poor transverse strength of bamboo, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

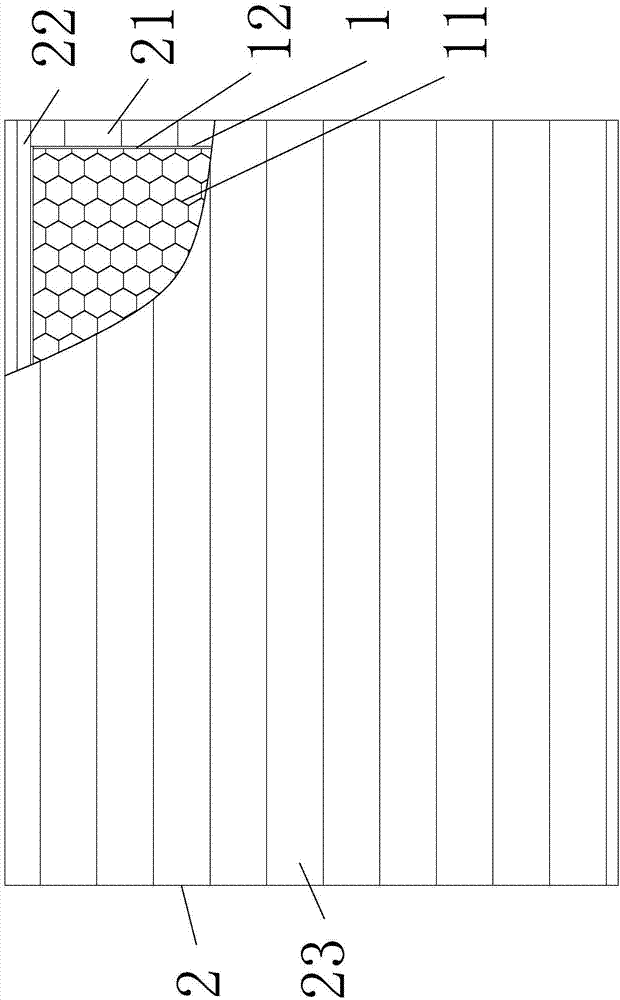

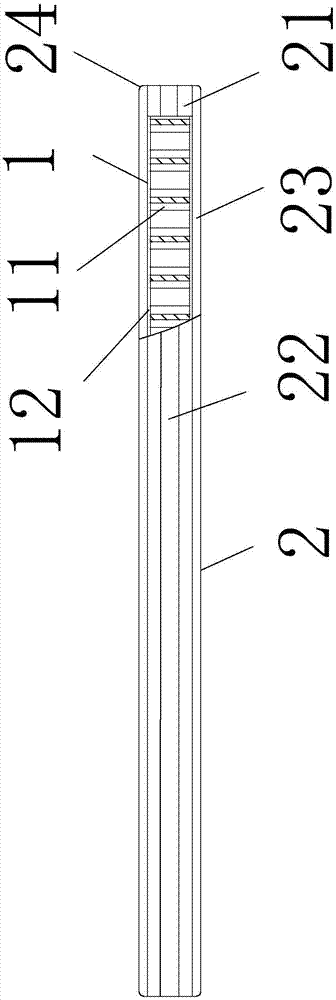

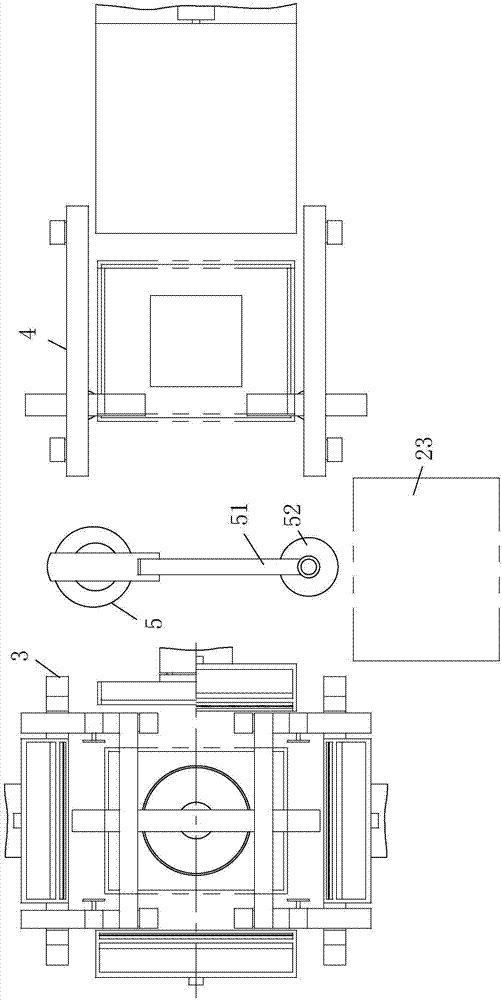

[0024] as attached figure 1 to attach Figure 7 Shown: a kind of composite board of honeycomb structure with full bamboo surface, comprising: composite core board 1, bamboo outer layer 2; The shape of composite core board 1 is rectangle; Composite core board 1 comprises paper honeycomb core board 11 and is coated on The medium density fiberboard layer 12 outside the core board 11; the bamboo outer layer 2 includes: two bamboo end strips 21 corresponding to the two end edges of the composite core board 1 and bonded by glue, two with the composite core board 1 The two sides of the two sides correspond to the bamboo side strips 22 bonded by glue and the two ends of the bamboo end strips 21, and the two bamboo panels 23; the upper end surface of the composite core board 1, the two The upper side of the bamboo end bar 21 and the upper sides of the two bamboo side bars 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com