Anti-shock internal mixer

An internal mixer and internal mixing technology, applied in mechanical equipment, engine components, engine lubrication, etc., can solve the problems of large noise, affecting work efficiency, and inconvenient maintenance, avoiding wear and ensuring stable work. performance, easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

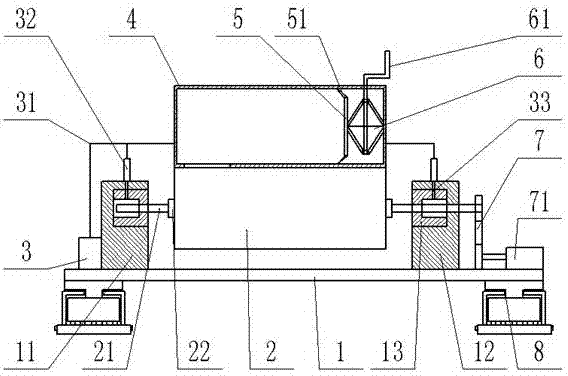

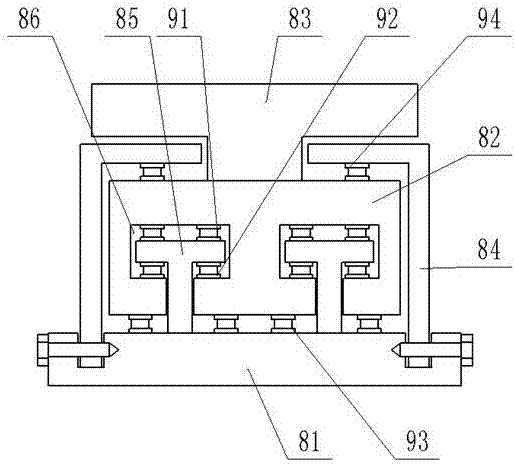

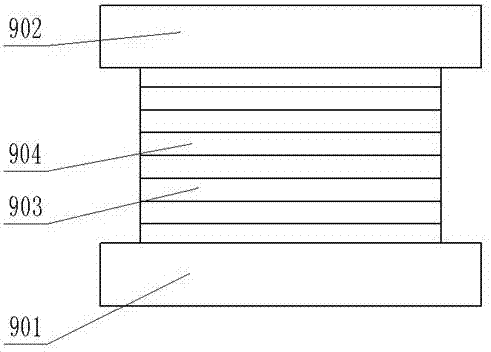

[0015] see Figure 1-3 , a shock-absorbing internal mixer that is easy to use, including a workbench 1, a mixing chamber 2, a material storage chamber 4 and a discharge plate 5, and the two ends of the workbench 1 are provided with a left fixing seat 11 and a right fixing seat 12. There is a banburying chamber 2 between the left fixing seat 11 and the right fixing seat 12. A banburying shaft 21 passes through the banburying chamber 2, and the banburying shaft 21 is connected with the bearing 22 fixed on the banburying chamber 2. The mixing chamber 2 is connected in rotation; the two ends of the mixing shaft 21 are respectively arranged in the sealing blocks 13 on the left fixing seat 11 and the right fixing seat 12, and the sealing blocks 13 are respectively embedded in the left fixing seat 11 and the right fixing seat 12 Inside, the sealing block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com