Waterpower propulsion system with water absorption passageway

A propulsion system and channel technology, applied in ship propulsion, propulsion components, rotary propellers, etc., can solve the problems of low redundancy, small size of power units, strong power, etc., so as to improve redundancy and improve sailing speed. , the effect of keeping clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

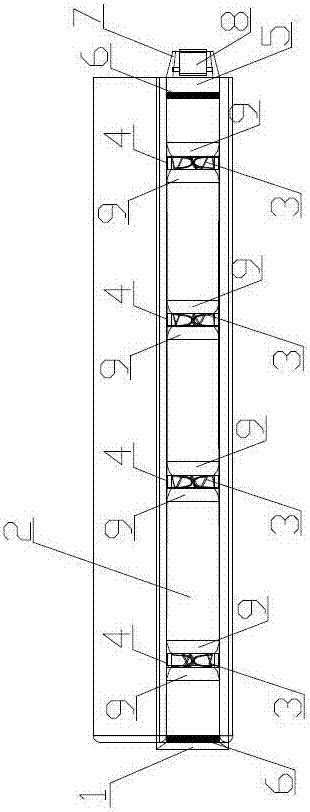

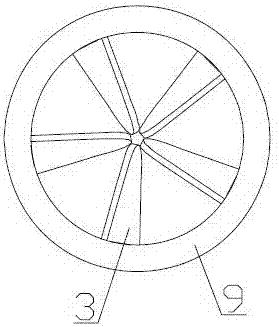

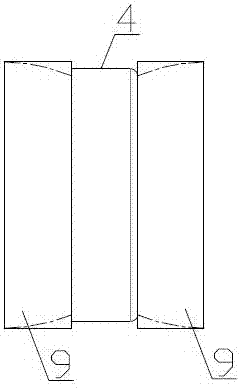

[0041] A hydraulic propulsion system with a water absorption channel, comprising a water inlet 1, a water absorption channel 2, a propeller 3, a propulsion motor 4 and a water outlet 5; the propeller 3 is located in the propulsion motor 4, and the propeller 3 is multi-stage set up.

[0042] The water absorption channel 2 of the present invention can run through the lower part of the hull, and the water sucked in the front is discharged from the water outlet at the stern through the water absorption channel 2 . The water absorption channel 2 of the present invention can be provided with multiple parallel and relatively independent structures of the water absorption channel 2 , and can also be designed as a structure in which multiple water inlets 1 share one water outlet 5 . The water absorption channel 2 of the present invention is circular or non-circular. In the hydraulic propulsion system, the water inlet 1 sucks the water in front of the ship, underwater robot and other h...

Embodiment 2

[0044] A hydraulic propulsion system with a water absorption channel, comprising a water inlet 1, a water absorption channel 2, a propeller 3, a propulsion motor 4 and a water outlet 5; the propeller 3 is located in the propulsion motor 4, and the propeller 3 is multi-stage set up.

[0045]Preferably, the water inlet 1 and the water outlet 5 are both provided with filter screens 6 .

[0046] Preferably or further, the water inlet 1 is trumpet-shaped.

[0047] Preferably or further, the water outlet 5 is provided with a frustum cylindrical part 7, and a fishtail rudder 8 is arranged in the cylindrical part 7 of the frustum.

Embodiment 3

[0049] A hydraulic propulsion system with a water absorption channel, comprising a water inlet 1, a water absorption channel 2, a propeller 3, a propulsion motor 4 and a water outlet 5; the propeller 3 is located in the propulsion motor 4, and the propeller 3 is multi-stage set up.

[0050] Preferably, the propellers 3 arranged in multiple stages are equally spaced and uniformly arranged in the water absorption channel 2 .

[0051] Preferably or further, the number of stages of the propeller 3 is 3-5.

[0052] Preferably or further, the number of blades of the propeller 3 is 4, 5 or 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com