Ground charging and conveying system of vehicle-mounted integrated soil remediation device

A soil remediation and conveying system technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as affecting remediation efficiency and inability to load multiple sets of remediation devices, and achieves easy maintenance and replacement, simple structure, and improved performance. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

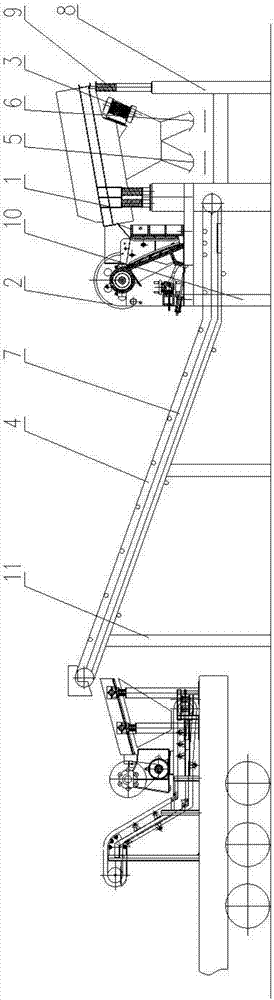

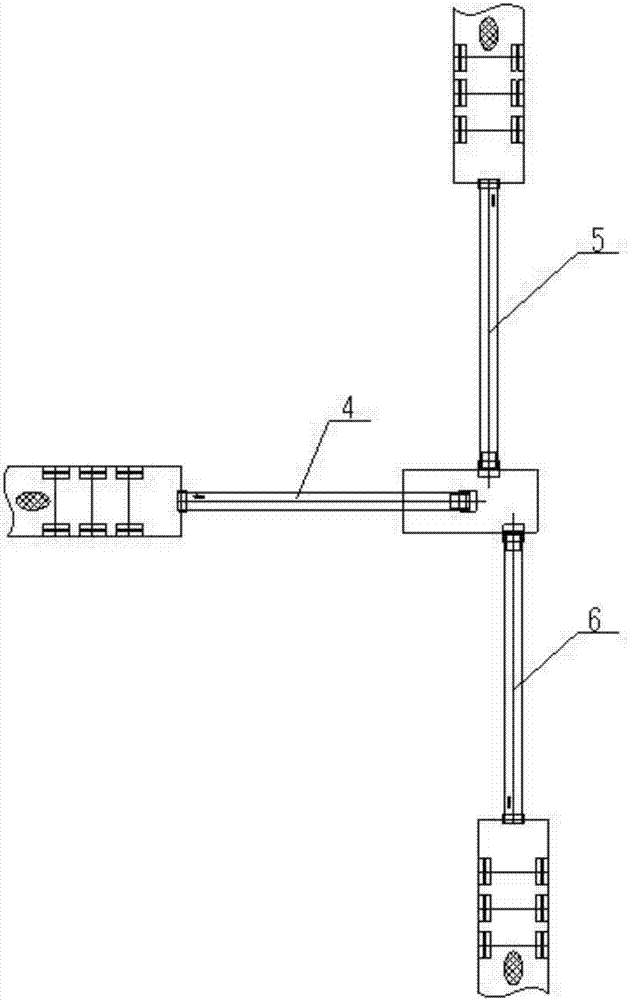

[0022] The present invention will be further described below in conjunction with the accompanying drawings. like Figure 1-2 Shown, a kind of vehicle-mounted integrated soil remediation device ground feeding conveying system comprises a feeding device and a belt conveying system; the described feeding device includes a vibrating feeder 1, a crusher 2 and a distribution funnel 3; the The vibrating feeder 1 is installed on the ground through the feeder bracket 8; the distributing funnel 3 is located below the vibrating feeder 1; the crusher 2 is located in front of the vibrating feeder 1. The machine support 10 is installed on the ground; the outlets of the vibrating feeder 1 and the crusher 2 are connected to the distribution funnel 3; there are multiple outlets below the distribution funnel 3, and each outlet corresponds to a set of belts Conveying system, the outlet of each belt conveying system corresponds to a set of soil remediation device.

[0023] Further, a damping sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com