Wire harness collecting device

A collection device and wire harness technology, applied in the field of wire harnesses, can solve the problems of high labor intensity, difficulty in collection, affecting production efficiency, etc., and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

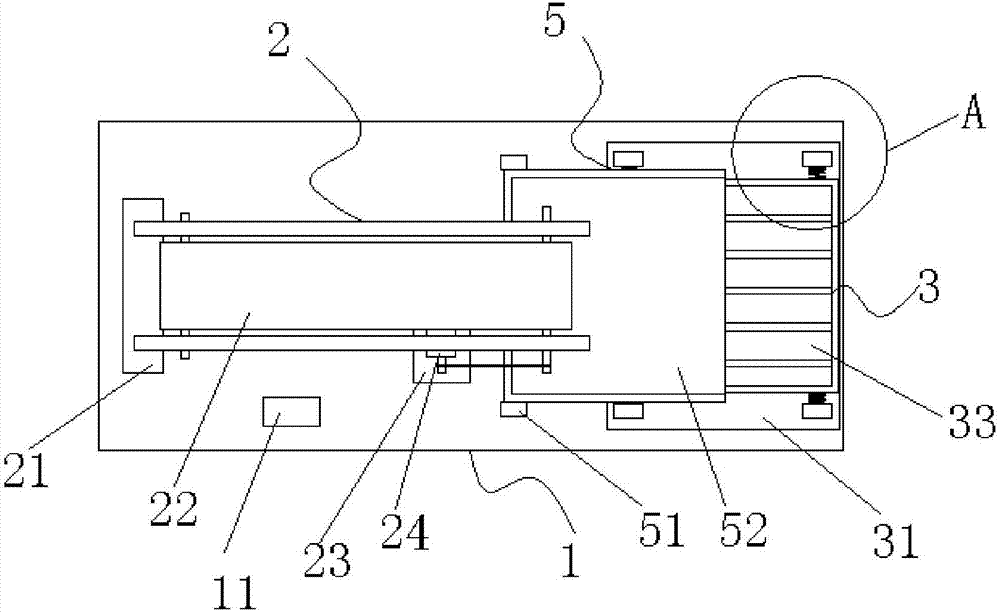

[0017] Such as Figure 1 to Figure 3 Shown is a specific embodiment of the present invention: a wire harness collection device, including a device base 1, a wire harness transport mechanism 2, a wire harness collection box assembly 3, a vibration motor 4 and a chute assembly 5, and the device base 1 is provided with a control 11, the wire harness transport mechanism 2 is fixedly connected to the device seat 1, the wire harness collection box assembly 3 is fixedly connected to the device seat 1, the chute assembly 5 is fixedly connected to the device seat 1, and the vibration motor 4 is connected to the wire harness The collection box assembly 3 is fixedly connected.

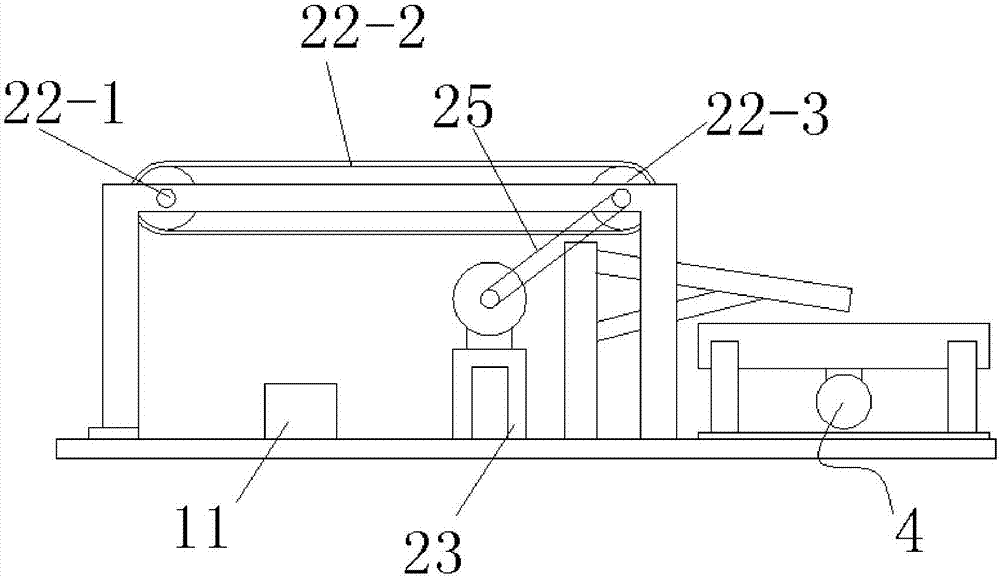

[0018] In this embodiment, the wire harness transportation mechanism 2 is composed of a bracket 21, a transportation assembly 22, a motor base 23, a motor 24 and a belt 25, and the transportation assembly 22 is composed of a driven wheel 22-1, a transportation belt 22-2 and a driving wheel 22-3, the driving whee...

Embodiment 1

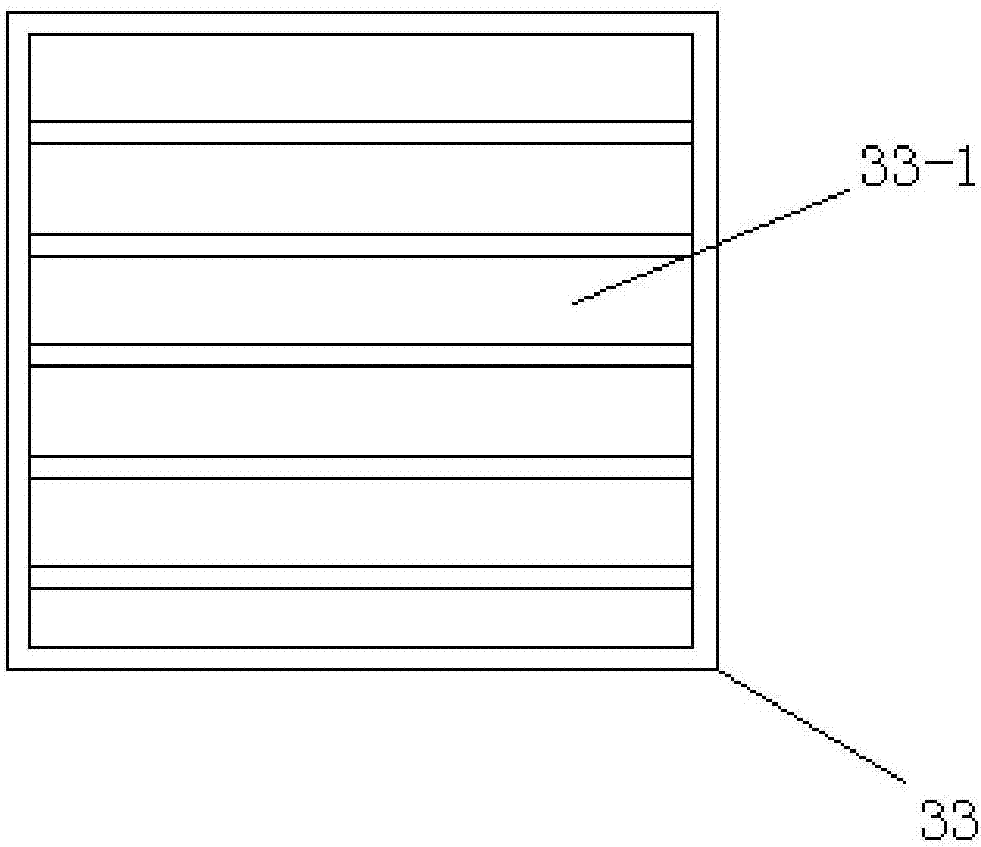

[0024] This invention is a wire harness collection device. When collecting wire harnesses, the motor 24 and the vibration motor 4 are started by the controller 11. The output shaft of the motor 24 drives the driving wheel 22-3 to rotate through the belt 25, and the driving wheel 22-3 drives the conveyor belt. 22-2 movement, when the wiring harness that needs to be collected falls on the conveyor belt 22-2, the conveyor belt 22-2 will transfer the wiring harness, and the wiring harness will fall into the chute 52 below after passing through the top of the driving wheel 22-3 , the chute 52 is arranged obliquely, and the wire harness will continue to slide down into the wire harness collection box 33 along the chute 52. Since the wire harness collection box 33 is divided into long sub-boxes 33-1, the wire harness actually falls on the In a sub-box 33-1, the wire harness collection box 33 is elastically connected with the wire harness collection box support 31 by four springs 32, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com