Anti-wrinkle finishing agent used for fabrics, preparation method and application thereof

An anti-wrinkle finishing agent and textile finishing technology, applied in textiles and papermaking, fiber treatment, plant fiber, etc., can solve the problem of discoloration of sulfur dyes and reactive dyes, lower dyeing rate of anionic dyes, poor wet rubbing fastness, etc. problem, to achieve the effect of excellent anti-wrinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

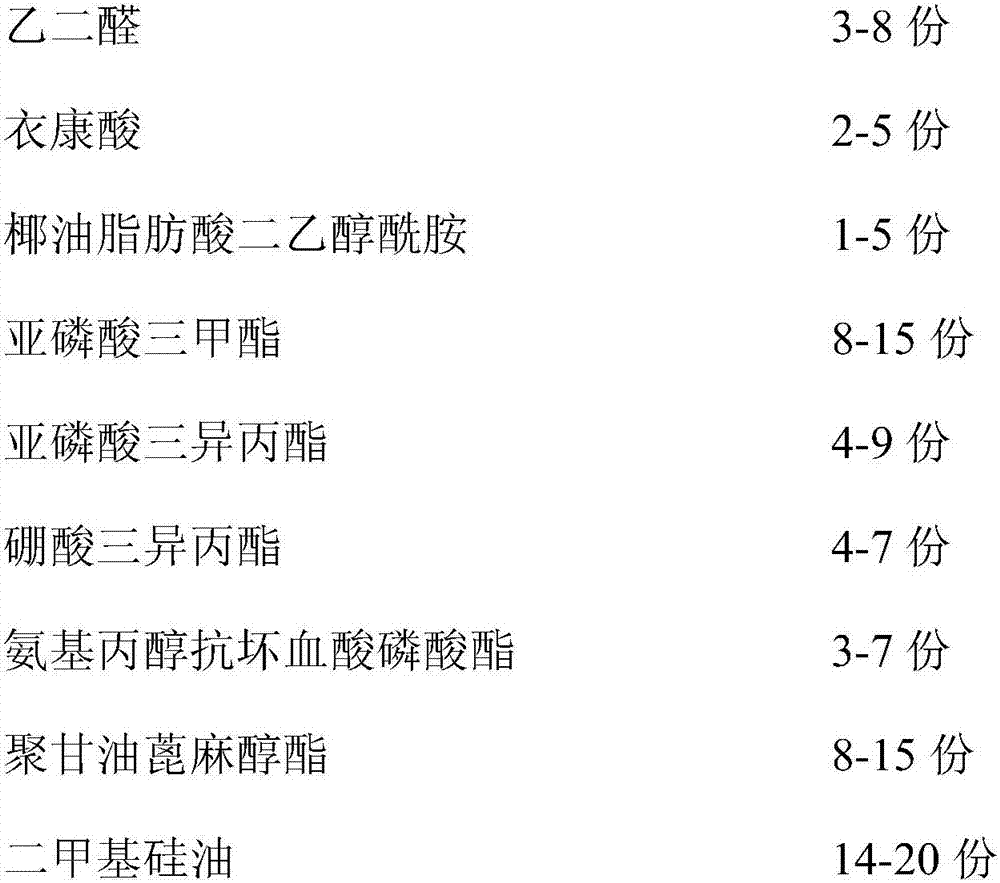

[0034] An anti-wrinkle finishing agent for textiles, comprising the following components by weight:

[0035]

[0036]

[0037] The preparation method of the anti-wrinkle finishing agent for textiles comprises the following steps:

[0038] (1) Take glyoxal, itaconic acid, coconut oil fatty acid diethanolamide, propylene glycol, and water by weight, heat the propylene glycol and water to 55°C, and after the temperature stabilizes, magnetically stir these components, and the magnetic stirring speed 100rpm, stir until uniform, it is mixed solution A;

[0039] (2) keep the temperature constant, slowly add polyglycerol castor, dimethicone, polydimethylsiloxanol stearate and secondary Alcohol polyoxyethylene ether, add the above-mentioned ingredients dropwise while performing magnetic stirring, the stirring speed is still 100rpm, stir until the above-mentioned ingredients are completely dissolved, and it is the mixed solution B;

[0040] (3) Keeping the temperature at 55°C, a...

Embodiment 2

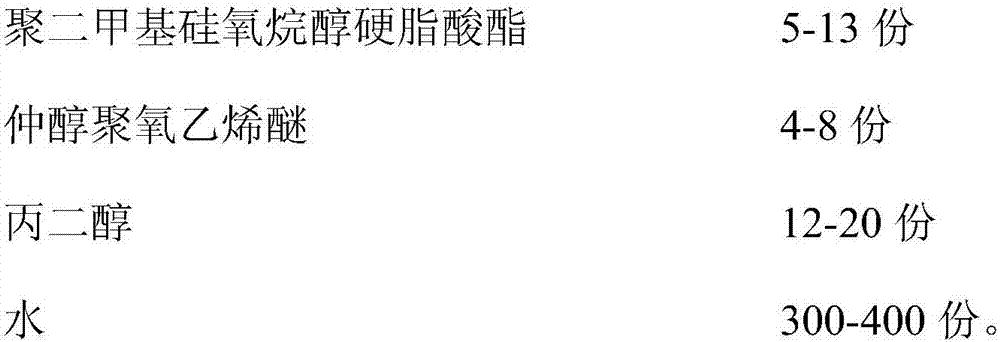

[0042] An anti-wrinkle finishing agent for textiles, comprising the following components by weight:

[0043]

[0044]

[0045] The preparation method of the anti-wrinkle finishing agent for textiles is the same as in Example 1.

Embodiment 3

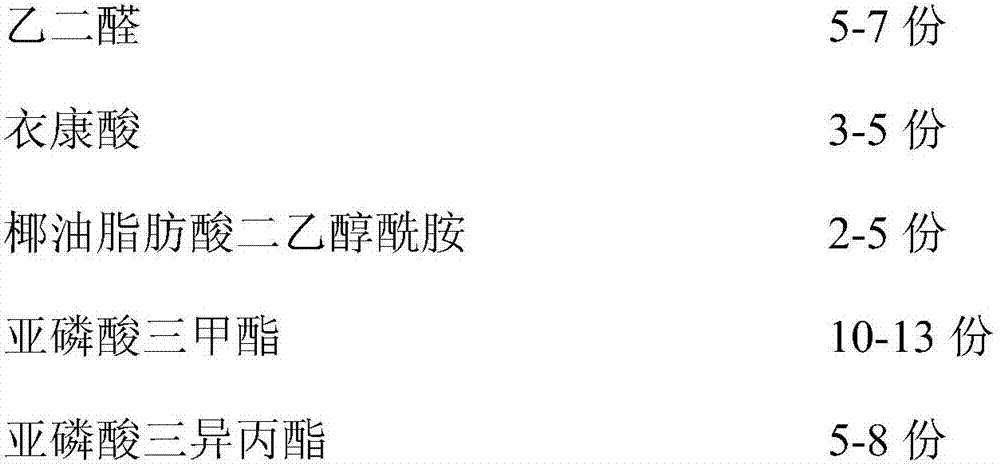

[0047] An anti-wrinkle finishing agent for textiles, comprising the following components by weight:

[0048]

[0049]

[0050] The preparation method of the anti-wrinkle finishing agent for textiles is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com