Door-closing buffer assembly

A technology of components and clips, applied in door/window accessories, wing parts, wing closers, etc., can solve the problem that the decoupling device and the buffer component cannot adjust the position of the interaction force by themselves, the installation of the damper is inconvenient, and the impact Issues such as service life and user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

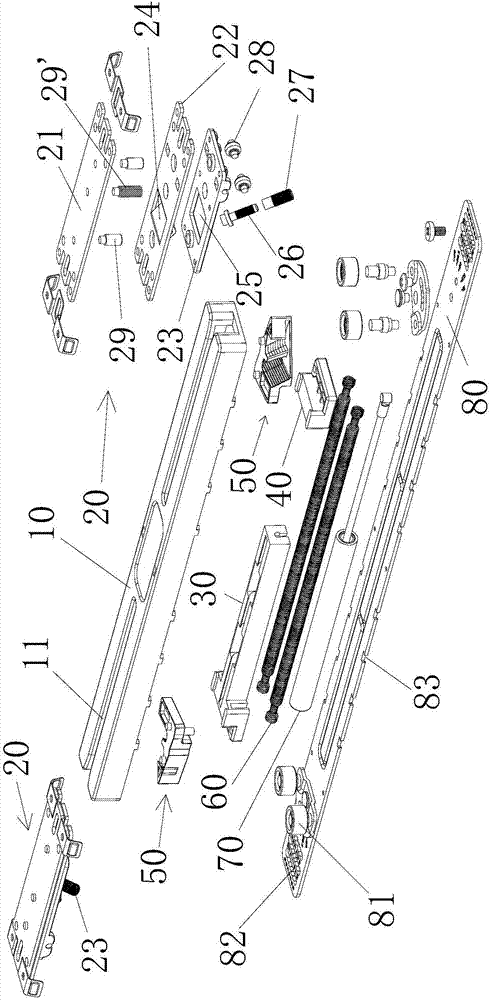

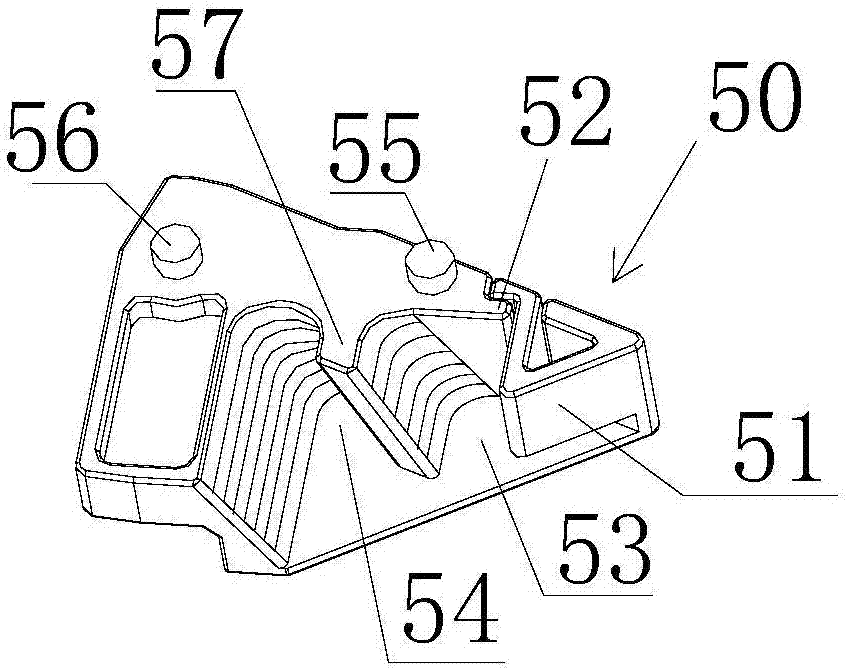

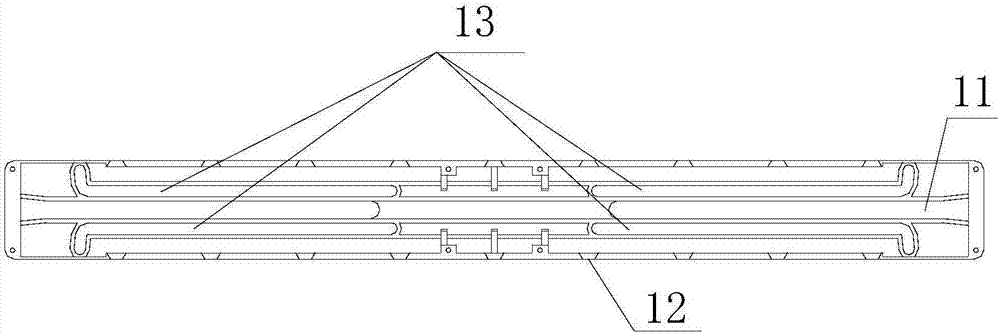

[0024] Such as Figure 1-7 As shown, a door closing buffer assembly of this embodiment includes a housing 10 provided with a groove 11, a limit device 20 provided with a toggle member 26, and a damping device provided in the housing 10. The described The toggle member 26 extends into the housing 10 through the groove 11. The damping device includes a spring 60, a damper 70, a sliding seat 40 and a decoupling device 50. There are two sliding seats 40, respectively connected to the spring 60. It is connected with the two ends of the damper 70, and the decoupling device 50 is also provided with two, and the two sliding seats 40 are rotatably connected with the two decoupling devices 50, and the described decoupling device 50 is provided with a first clip position 53 and The second clamping position 54, the first clamping position 53 is surrounded by the elastic baffle 51 and the protruding part 57 on three sides, and the second clamping position 54 is concaved by the protruding p...

Embodiment 2

[0026] Such as Figure 1-7 As shown, this embodiment has been improved on the basis of Embodiment 1. The decoupling device 50 is also provided with a bullet-resistant component 52, and the elastic component 51 is provided with a hook. After the elastic component 51 rebounds, the hook hooks on the resistance On the spring part 52. Due to the active force of the spring 60, the uncoupling device 50 is closely attached to the sliding seat 40, and the front end of the uncoupling device 50 is arranged in a triangle, and the elastic part 51 is installed on one face of the triangle, and the toggle part 26 hits the elastic part 51, and the elastic part 51 The component 51 bounces open, the toggle piece 26 enters the first clamping position 53, and then the elastic component 51 bounces back to form an accommodation area together with the first clamping position 53, and the bullet-resistant component 52 restricts the rebound of the elastic component 51 itinerary. At this time, no matte...

Embodiment 3

[0028] Such as Figure 1-7 As shown, this embodiment improves the movable installation method of the decoupling device 50 and the sliding seat 40, the sliding seat 40 is provided with a fulcrum hole 41, the decoupling device 50 is provided with a fulcrum column 56, and the fulcrum The column 56 is arranged in the fulcrum hole 41 , and the decoupling device 50 rotates relative to the decoupling device 50 through the fulcrum column 56 , and the sliding seat 40 is also provided with a sliding guide boss 42 . The uncoupling device 50 takes the fulcrum column 56 as a fulcrum and rotates relative to the sliding seat 40 , but due to the effect of the spring 60 , the uncoupling device 50 is closely connected with the sliding seat 40 without being affected by other external forces. The guide boss 42 plays a role in making the sliding seat 40 move directionally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com