Steam extraction and heat supply system capable of flexibly cutting off low-pressure cylinder and control method

A technology of steam extraction for heat supply and control method, which is applied in the direction of steam application, steam engine device, combined combustion mitigation, etc. It can solve the problems of low heat supply capacity and poor operation adjustment flexibility of steam extraction heat supply units, so as to improve the heat supply capacity and peak shaving capacity and unit load adaptability, and the effect of economic transformation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

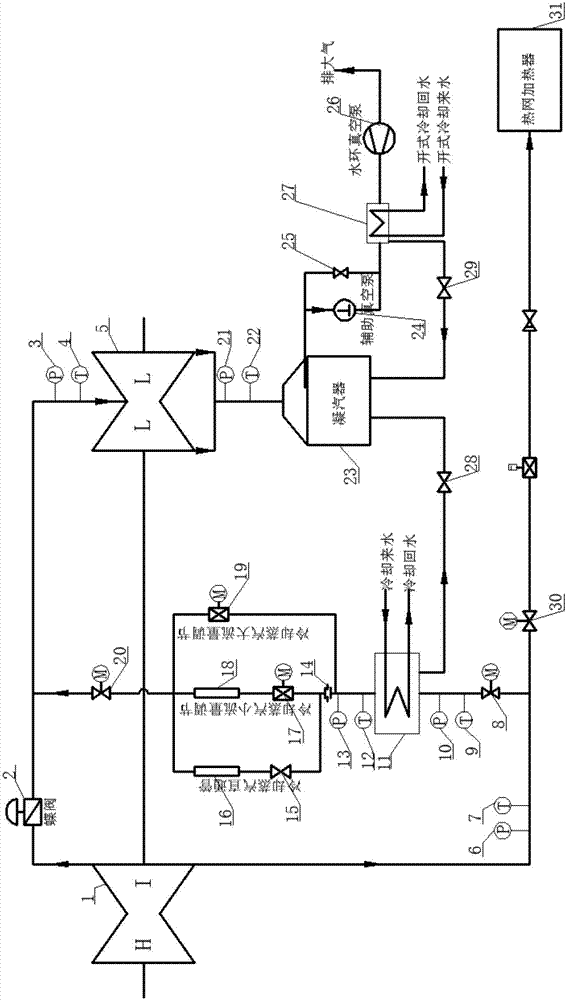

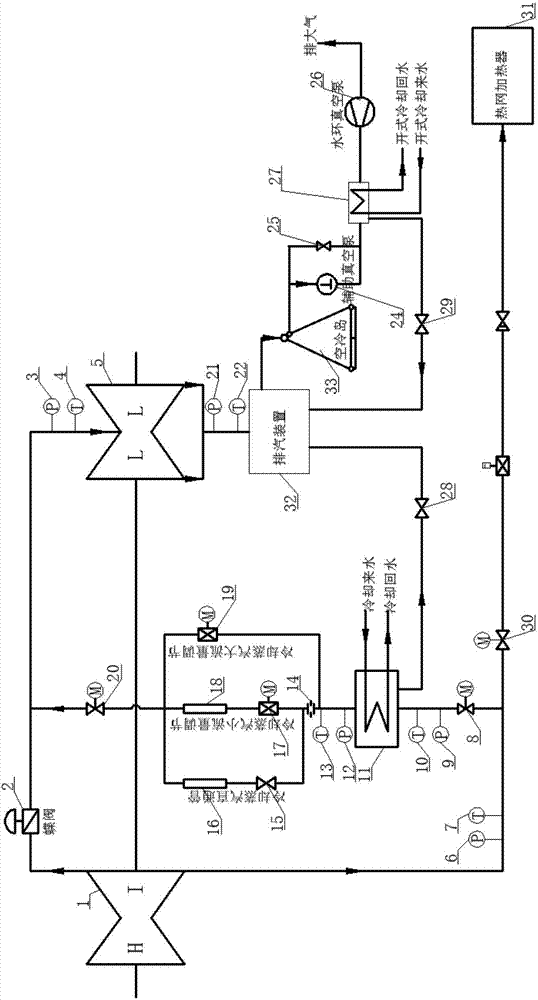

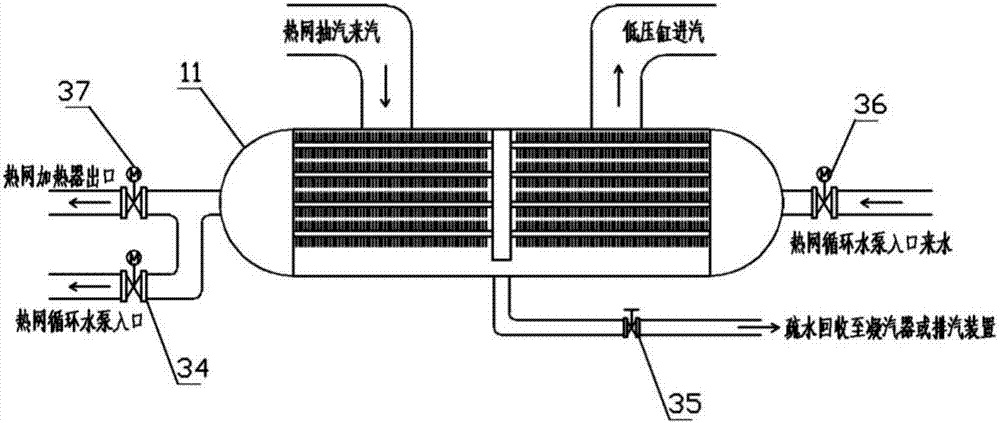

[0033]The steam extraction heating system of the prior art steam extraction heat supply unit directly supplies steam to the heating network heater, and the pressure of the heating and extraction steam is adjusted through the low-pressure cylinder steam inlet butterfly valve to ensure the safe operation of the low-pressure cylinder. During the hot period, the back pressure of the wet cooling unit is maintained at 4-6kPa, the back pressure of the air-cooling unit is maintained at 8-10kPa, and a single low-pressure cylinder guarantees a minimum intake cooling flow of 120-150t / h. At this time, the final blade of the low-pressure cylinder is already in a certain blowing operation state, the actual efficiency of the final blade of the low-pressure cylinder is lower than 30%, and the final stage of some units may also have negative work. Under such back pressure conditions, if the inlet steam flow rate of the low-pressure cylinder is further directly and greatly reduced, the blowing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com